Production CNC machining is a manufacturing approach commonly used by teams and individuals when repeatable tolerances, stable capacity, and predictable unit costs are required, while avoiding early investment in tooling costs and lead time. In CNC machining, the objective is production speed and batch consistency, not merely producing a single qualified part. When properly executed, CNC machining provides scalable and reliable delivery for industries with high requirements for precision and traceability.

Processing Scope of Production CNC Machining

Production CNC machining achieves repetitive operations of the same design through coordinated processes such as CNC milling, CNC turning, CNC grinding, conventional lathes, conventional milling, and supporting secondary operations (such as electrical discharge machining for excess material removal and part separation), under optimized machining steps.

A typical production project usually includes:

- Verified toolpath programs

- Dedicated fixtures and reliable vises matched to the material

- Controlled tool life management

- Standardized inspection workshops

Unlike conventional “job-shop” machining, production CNC machining relies more heavily on standardized operations, change control, and statistical sampling inspection.

What Makes It “Production-Oriented”

In production CNC machining, you will typically see:

- Repeatable fixturing and clamping systems with stable datums

- Verified cutting parameters and designated tool life supervisors

- Process measurement (in-process inspection and sampling) with defined inspection frequency

- Optimization and change control of 3D models, drawings, and machining steps

Why Choose Production CNC Machining

Companies choose production CNC machining to maintain controlled tolerances and precision while gaining a flexible path to volume manufacturing. For many products, CNC machining can even serve as the long-term final process, as it enables stable mass production without the cost and lead time of molds.

Key Advantages

- Scalable precision: Production CNC machining maintains positional accuracy and consistent surface quality over long production cycles.

- Faster production start than tooling-based processes: Once material selection, fixturing, and program validation are complete, production can begin.

- Agile design iteration: Engineering changes are implemented through software and process adjustments, making it suitable for product iteration phases.

- Multi-material compatibility: Metals and engineering plastics can be processed within the same production system, reducing changeover costs.

When to Use Production CNC Machining

A practical guideline is to adopt production CNC machining when the design is stable enough to be standardized and production volume can amortize fixture and process validation costs. Many teams use production CNC machining during product ramp-up and later evaluate whether to transition to casting, stamping, or injection molding.

Optimal Triggers

Production CNC machining is more suitable under the following conditions:

- Monthly demand becomes predictable (hundreds to thousands of units)

- Critical dimensions require controlled capability rather than experience-based adjustment

- Complex geometry (multi-face features, thin walls, strict GD&T requirements)

- A need to bridge production before investing in hard tooling

- Market or field feedback may drive design revisions, where production CNC machining avoids tooling sunk costs

Core Processes in Production CNC Machining

Production CNC machining typically consists of a series of linked processes, focusing on reducing part repositioning and preserving positional relationships between features.

CNC Milling in Batch Production

For simple parts such as single-face milled components, 3-axis milling is commonly used to control costs. When reduced reorientation, curved cavities, or multi-face machining is required, 4-axis or 5-axis machining is introduced. Generally, fewer setups result in better geometric consistency and lower labor content.

CNC Turning and Mill-Turn

For shafts, bushings, sleeves, and threaded parts, CNC lathes with live tooling are commonly used. Mill-turn machines allow more features to be completed in a single setup, improving concentricity and enabling integrated turning and milling for one-stop component manufacturing.

Secondary Operations and Surface Treatments

A mature production CNC machining route often includes chamfering, deburring, bead blasting, anodizing, plating, passivation, heat treatment, laser marking, and light assembly. Since surface treatments may affect dimensions, drawings should clearly specify post-treatment dimensions where required to avoid batch dimensional deviations.

Common Raw Materials for Production CNC Machining

Materials determine performance and machinability. Qualified suppliers match inventory, heat treatment conditions, and surface treatment compatibility based on customer requirements and application scenarios to ensure long-term production stability.

Common Metal Materials

- Aluminum (6061, 7075, 6082): Lightweight and easy to machine, widely used for electronic enclosures, heat dissipation components, robotic structures, and aerospace brackets.

- Stainless Steel (303, 304, 316, 17-4PH): Corrosion-resistant, commonly used for medical devices, food equipment, deep-sea equipment, and hardware.

- Carbon Steel / Alloy Steel (1018, 4140): Balanced strength and cost, suitable for industrial fixtures and automotive structural parts.

- Brass and Copper Alloys: Used for bushings, fittings, electrical contacts, and heat-related components.

- Titanium (Grade 2, Grade 5): High strength-to-weight ratio and corrosion resistance, commonly used in aerospace and corrosion-resistant assemblies produced via production CNC machining.

Plastics and High-Performance Polymers

- ABS, Nylon (PA), Acetal (POM): Used for housings, spacers, and low-friction functional parts.

- PEEK, PTFE, UHMW: Used in chemical-resistant, wear-resistant, and high-temperature environments, commonly in semiconductor, medical, and laboratory equipment.

Application Industries and Typical Parts

Production CNC machining is suitable for industries that require high dimensional precision, consistency, and stable delivery.

Aerospace and Defense

Production CNC machining is used to manufacture brackets, sensor mounts, avionics housings, hydraulic manifolds, and structural connectors. Typical accessories include thread inserts, press-fit/self-locking fasteners, dowel pins, and precision bushings to ensure assembly consistency.

Automotive and New Energy Vehicles (EV)

In the automotive sector, production CNC machining is commonly used for engine components, motor mounts, transmission housings, battery tray hardware, suspension spacers, precision shafts, and thermal management plates. Retaining CNC machining during ramp-up avoids mold tooling scrap risks during iteration.

Medical and Laboratory Equipment

Production CNC machining is widely used for instrument housings, pump bodies, imaging fixtures, laboratory automation platforms, and surgical tool subassemblies. Accessories may include easy-to-clean fasteners, fluid fittings, and high-precision locating features that rely on consistent machining capability.

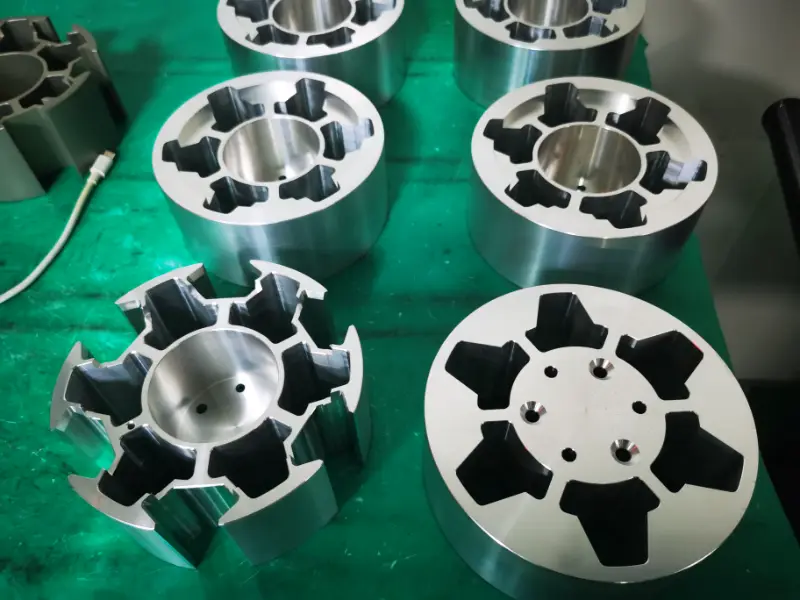

Industrial Automation and Robotics

Production CNC machining enables batch manufacturing of end effectors, grippers, bearing blocks, gearbox end plates, linear actuator components, and precision fixtures. These systems typically require strict flatness, hole position accuracy, and fit consistency.

Electronics and Telecommunications

Production CNC machining is commonly used for aluminum enclosures, RF shielding components, connector blocks, antenna mounts, and heat sinks. Typical features include O-ring grooves, EMI gasket channels, and threaded bosses.

Quality Control Key Points in Production CNC Machining

Quality is one of the core values of production CNC machining. A controlled inspection plan reduces variation and prevents long-term production drift.

Practical QC Components

- Incoming material verification and material certificate review

- In-process inspection (pin gauges, calipers, micrometers) for critical-to-quality (CTQ) dimensions

- Final inspection using vernier calipers, micrometers, height gauges, and projectors; CMM inspection for hard-to-measure features

- Corrective and response mechanisms when trends approach tolerance limits

Through these controls, production CNC machining maintains stable process capability across batches and workstations.

Cost Drivers and Cost Reduction Methods

The main cost drivers of production CNC machining include machining time, number of setups, tool wear, material size and utilization, and surface treatments. Clear requirements help suppliers optimize production CNC machining rather than adding risk premiums.

Common Cost Reduction Levers

- Relaxing tolerances on non-critical features

- Using standard hole sizes, standard threads, and reasonable fillets

- Combining operations and reducing setup changes to improve CNC machining efficiency

- Requiring higher surface finish standards only where function or appearance demands

- Providing accurate annual volume forecasts to amortize fixture and inspection tool investments

How to Select a Production CNC Machining Supplier

Production CNC machining competitiveness depends not only on equipment, but also on process systems and machining discipline. The right partner significantly reduces batch variation and delivery risk.

Supplier Evaluation Criteria

- Equipment capability (3/4/5-axis milling, EDM—both wire-cut and slow-wire, live-tool turning, conventional lathes and mills)

- Quality system maturity (ISO 9001; IATF 16949 for automotive projects)

- Tool life management, revision control, and standardized work documentation

- Surface treatment capability and clear, controllable packaging standards

- Ability to provide timely DFM feedback and continuously optimize production CNC machining outcomes

Conclusion

Production CNC machining is a practical path to scalable, repeatable, and high-consistency parts manufacturing. By selecting CNC machining at the right time and aligning material selection, inspection strategies, and surface treatment requirements with suppliers, stable mass production and controlled costs can be achieved across aerospace, automotive, medical, industrial automation, and electronics projects.

If you would like additional information or a machining quotation, please contact Weldom Machining.