“What’s the biggest fear when turning a product from design to reality? It’s definitely ‘the finished product doesn’t match the specifications!’ Redesigning, rework, wasting materials—time and money are all wasted. That’s where prototype cnc machining comes in—it’s like a ‘fast, accurate, and efficient translator’—give a 3D drawing, and it can turn your idea into a physical object in just a few hours, with a precision of up to 0.01 millimeters. Surface smoothness and roughness can be adjusted! Phone case curvature, medical parts, lightweight aircraft structures—all can be molded in one go without repeated modifications. Designers can quickly verify, engineers can correct errors in advance, and bosses can save on trial production costs. In short, Fast cnc machining is the key to ‘avoiding pitfalls and speeding up’ innovation!”

Process Types and Accuracy Characteristics of Prototype CNC Machining

Multi-Axis Prototype CNC Machining Technology Characteristics

3 Axis CNC machining achieves planar or simple curved surface machining through X/Y/Z 3-axis linkage, with an accuracy of ±0.01~0.03mm. It is suitable for structural verification prototypes such as electronic housings. Its technical advantages lie in low equipment cost and simple programming.

4 Axis CNC machining adds an A-axis rotation function to the 3-axis model, realizing the machining of complex contours such as eccentric holes and gear blanks, improving the accuracy to ±0.005~0.02mm.

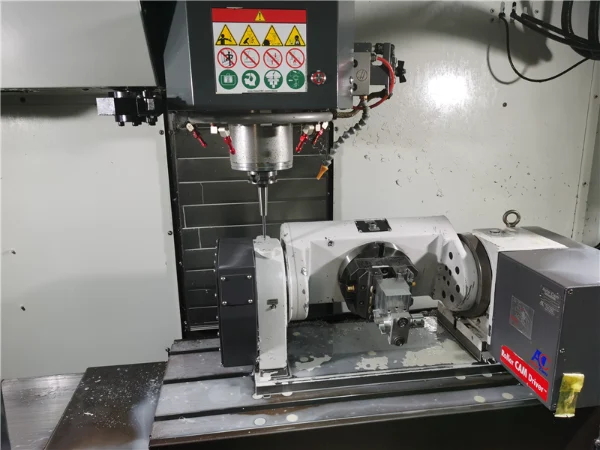

5 Axis CNC machining uses A/C dual rotary axis linkage, achieving an accuracy of ±0.002~0.01mm, meeting the needs of multi-faceted prototype machining and complex curved surface prototypes. Our Weldo machine center, using Haas and Hurco 5-axis CNC machines, can perform precision milling on prototypes of various sizes, achieving positioning accuracy of 0.002mm and surface roughness of Ra 0.08μm.

Ordinary milling machines, through manual or motorized X/Y/Z axis feed, perform multi-blade intermittent cutting on workpieces, producing planes, grooves, stepped surfaces, and simple curved surfaces, with machining accuracy of ±0.05~0.1mm and surface roughness Ra 3.2~6.3μm.

Ordinary cnc lathes, through the coordination of workpiece rotation and tool linear motion, achieve machining of rotating parts, with form and position tolerances: roundness ±0.02mm and cylindricity ±0.05mm. Surface roughness: Ra 1.6~6.3μm.

CNC Turning and Milling Table Process Characteristics

CNC lathe spindle speed: 800-2000rpm, machining accuracy: IT7-IT8 grade (±0.015-0.03mm), suitable for machining shaft prototypes such as motor shafts.

Ordinary milling lathes are operated manually/semi-automatically, with an accuracy of ±0.05~0.1mm, suitable for low-precision, high-speed prototyping such as mechanical supports. Although their machining efficiency is lower than that of CNC equipment, the equipment cost is only 1/5 of that of a 3-axis machining center, making them suitable for production processing with lower precision requirements and smaller production quantities.

Accuracy-Complexity-Cost Three-Dimensional Comparison

| Process Types | Accuracy Range | Typical Scenarios | Cost Levels (per Hour) |

| 3-Axis CNC | ±0.01~0.03mm | Electronic casings, simple structure verification | $20~45 |

| 5-Axis CNC | ±0.002~0.01mm | Turbine blades, precision molds | $80~200 |

| CNC lathe | ±0.015~0.03mm | Motor shafts, disc-type parts | $15~30 |

| CNC mills | ±0.05~0.1mm | Mechanical supports, low-precision frames | $10~20 |

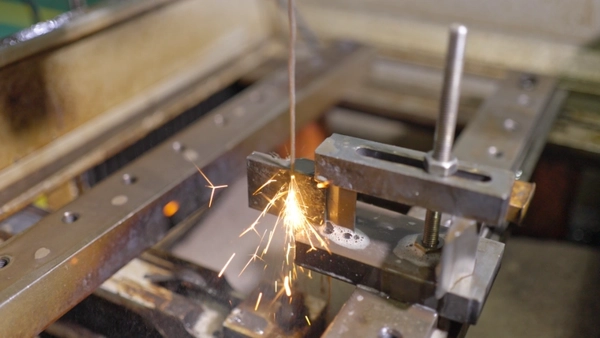

Wire EDM, as a specialized process, achieves a precision of ±0.002mm and a surface roughness of Ra0.4μm with slow wire EDM, making it suitable for prototypes of difficult-to-machine materials such as cemented carbide. Medium wire EDM, through multiple cutting techniques (roughing 120mm²/min + finishing 40mm²/min), achieves a balance between precision and efficiency of ±0.005mm.

Material Compatibility of Metal and Plastic Prototypes

Metal Prototype Material Compatibility

Metal prototype machining requires matching process parameters based on material properties. The core material compatibility is as follows:

Aluminum (6061-T6): Suitable for 3/4-axis machining, cutting speed 150-300 m/min, UTS up to 260-310 MPa, surface finish Ra≤1.6 μm.

Stainless Steel (304): Recommended for 4-axis or CNC turning, cutting speed 80-120 m/min. Requires carbide tools with efficient cooling to avoid work hardening. Its corrosion resistance is suitable for medical stents and food equipment, with an accuracy of ±0.005 mm.

Titanium Alloy (TC4): Requires 5-axis machining with -10℃ cold air cooling, accuracy control ±0.005 mm. Due to poor thermal conductivity (7.2 W/m·K), low-speed cutting (800-1500 rpm) and special grinding wheels are required.

Brass (H62/C26000): Cutting speed 120-250 m/min, UTS 320-380 MPa, surface Ra≤0.8μm, suitable for 3/4-axis machining of high-precision decorative parts and corrosion-resistant components.

Bronze (Tin Bronze QSn6.5-0.1): Cutting speed 80-150 m/min, UTS 400-500 MPa, high wear resistance, specifically designed for rigid 3-axis machining of heavy-duty gears and bearing bushings.

Magnesium Alloy (AZ91D): High-speed cutting 300-600 m/min, UTS 220-280 MPa, significant lightweight advantage, suitable for high-efficiency 3-axis machining of 3C housings and aerospace structures.

Alloy steel (42CrMo4/AISI 4140): Low-speed hard machining at 60-120 m/min, UTS 980-1080 MPa, high strength and fatigue resistance, suitable for 4/5-axis precision forming of drive shafts and mold mandrels.

Plastic Prototype Material Compatibility

Plastic prototypes require a balance between machining efficiency and thermal deformation control. Typical material processing characteristics are as follows:

ABS: Suitable for 3-axis milling, easy to paint and electroplate, cost $2-5/kg. Its butadiene composition can form loose pores, and the electroplating adhesion reaches grade 5B.

PEEK: High temperature resistance up to 260℃, requires 5-axis machining for complex medical prototypes, price $50-150/kg. Compressed air cooling and vibration damping tool holders are required during machining to ensure dimensional stability of thin-walled parts.

POM: Low coefficient of friction (0.08), suitable for turning gear prototypes, tolerance control ±0.03mm. Cutting temperature must be controlled to avoid melting; carbide tools and coolants are recommended.

PC: Suitable for 3/5-axis high-speed milling, with high surface hardness (pencil hardness 2H-3H), excellent impact resistance, and a cost of $8-15/kg. Its bisphenol A structure gives the material high light transmittance (over 90%) and heat distortion temperature (130-140℃), achieving 4B adhesion after spraying, making it suitable for optical lenses and weather-resistant structural components.

PMMA: Suitable for 3-axis precision cutting, with a surface gloss of over 92% and light transmittance of 92-93% (close to glass), and a cost of $3-8/kg. Its methyl methacrylate monomers polymerize to form dense molecular chains, achieving 5B electroplating adhesion (requires pretreatment activation), and is widely used in display racks and light guide plate processing.

Material cost is positively correlated with performance: ordinary plastics (ABS, POM) cost $2-5/kg, while high-performance plastics (PEEK) cost $50-150/kg.

Cost-Benefit Analysis of Prototype CNC Machining

Cost Composition Analysis: The core costs of prototype CNC machining consist of equipment depreciation, tool consumption, and labor costs. Regarding equipment, the annual depreciation rate for 3-axis CNC is 15%, while for 5-axis equipment it reaches 25% due to rapid technological iteration. Furthermore, the hourly rate for 5-axis CNC (US$75-150) is significantly higher than that of 3-axis (US$40-75). In terms of tool costs, carbide tools have a lifespan of approximately 800-1200 pieces/cutting edge. Labor costs can be reduced by 60% through automated machining.

Benefit Comparison Model: Constructing a “precision-cost-cycle” triangle model reveals that the cost per piece for 3-axis machining is 20-50 usd, with a cycle time of 1-3 days, suitable for proof-of-concept. While the cost for 5-axis machining reaches 100-300 usd and the cycle time is 3-7 days, clamping errors are reduced by more than 50%, improving the reliability of functional verification. Material selection directly impacts efficiency: the cost of a 6061 aluminum alloy prototype (±0.1mm accuracy) is 1-3 usd per piece, while the processing cost of titanium alloy is 8-10 times higher. Yield is cost-sensitive; in one case, a 95% yield rate reduced material waste costs by 23% compared to an 80% yield rate.

Optimization Strategy Practices:

Process Substitution: Using “3-axis milling + manual grinding” reduces costs by 30% compared to pure 5-axis machining.

Material Optimization: Replacing titanium alloy with aluminum shortens processing time by 40%, and the cost of anodizing 6061 aluminum alloy is only 1/4 that of 7075 aluminum alloy.

Design Improvement: Modular design reduces processes by 30%.

Application of Prototype cnc machining

Prototyping, utilizing computer-aided design and CNC machine tool technology, rapidly produces product prototypes to validate designs, and is widely used in the following fields:

Automotive Industry

Parts Testing: Prototype parts are manufactured for load and vibration testing to identify design issues early and reduce costs.

Lightweight Design: Lightweight materials such as aluminum and magnesium alloys are machined to reduce part weight while maintaining strength.

Aerospace

High Precision Requirements: Machining parts with stringent material and structural requirements ensures aircraft safety and reliability.

Complex Shape Machining: Multi-axis CNC machine tools are used to machine complex geometric parts to meet design requirements.

Medical Devices

Precision Compliance: Producing precision parts that meet medical standards (such as surgical instruments and implants) ensures safety.

Rapid Time to Market: Accelerating product prototype testing and validation shortens the medical device development cycle.

Consumer Goods Industry

Appearance Evaluation: Rapidly creating product appearance models for design effectiveness evaluation and improvement.

Customized Production: Supporting small-batch, high-precision parts machining to meet personalized needs.

Other Fields

Electronic Products: Testing the casing and internal structure to ensure product reliability and stability.

Arts and Culture: Used for the reproduction of cultural relics, the design and manufacture of sculptures and arts and crafts.

Technological Trends and Optimization Directions of Prototype CNC Machining

Prototype CNC machining is achieving breakthroughs in high precision and efficiency through technological integration, forming a complete closed loop of “technological foundation – application practice – future trends”. In multi-axis and additive hybrid manufacturing, the “3D printed blank + CNC precision machining” model shortens the prototype cycle of aerospace brackets by 57% (from 7 days to 3 days) and reduces material waste by 50%, making it particularly suitable for rapid prototyping of complex aerospace structural parts. Intelligent prototype development relies on an AI-driven process parameter library (such as automatic matching of 1500-3000rpm speed for 6061 aluminum alloy) and digital twin technology (prediction error ±0.003mm) to achieve autonomous programming and pre-simulation of machining deformation. Integrated material-process design, through DFM review and optimization of the structure (thin-walled ≥1.5mm to prevent deformation), combined with the “anodic oxidation + laser etching” composite process, solves the surface quality problems of complex prototypes and reduces mass production process adjustment costs by 30%.

FAQ of prototype cnc machining

What is Prototype CNC Machining?

Prototype CNC machining is a rapid manufacturing method based on computer numerical control (CNC) technology. It uses pre-programmed software to control a machine tool, precisely cutting and shaping materials such as metals and plastics to obtain functional prototypes or parts that meet design requirements. Its advantages include high precision (±0.01mm), high repeatability, the ability to machine complex geometries, and support for multiple materials. It is a key technology for verifying design feasibility during the product development phase.

What are the commonly used materials for prototype CNC machining?

Metal materials: Aluminum (such as aerospace aluminum), stainless steel, steel, brass, etc. Aerospace aluminum can achieve a machining precision of 0.01mm, suitable for high-strength structural prototypes.

Plastic materials: ABS, nylon (PA11/PA12), polyoxymethylene (POM), polycarbonate, etc. Soft plastics (such as PVC) are prone to sticking to the tool and require special treatment.

Composite materials: Fiber-reinforced plastics, etc., require specialized tools and machining parameters. Different materials have significantly different machining characteristics. For example, the surface roughness of stainless steel after mirror polishing can reach Ra 0.05μm, and POM machining requires controlling internal stress to prevent deformation.

What is the typical workflow and cycle time for prototype CNC machining?

Workflow: Design and modeling → Programming → Material clamping → Machining → Post-processing.

Programming: Mainstream software such as Mastercam and Siemens NX; professional tools such as HyperMill for multi-axis machining.

Cycle Time: Simple 2D parts: a few hours; complex 3D/5-axis parts (such as turbine disks): several days, depending on part complexity, material hardness, and surface quality requirements.

Post-processing: Sandblasting, anodizing, electropolishing, etc., accounting for 20%-30% of the total cycle time.

How to solve common problems in prototype CNC machining?

Insufficient accuracy: Calibrate machine tool levelness, optimize fixtures, control rotary axis indexing errors (4-axis machining ≤ ±0.015°).

Surface roughness: Adjust cutting parameters, replace worn tools, electropolishing (Ra can be reduced to below 0.05μm).

Material deformation: Layered cutting for plastic parts; stress relief treatment before machining metal parts, such as annealing of aluminum alloys.

Cost Comparison of CNC Machining for Prototypes with Other Molding Technologies?

Small Batch Prototypes (1-50 pieces): CNC machining has a cost advantage.

Equipment Costs: 4-axis vertical milling machines vary in price depending on configuration, suitable for small and medium-sized enterprises.

Unit Cost: Simple metal prototypes cost approximately 8-30 usd/piece; complex structures (such as medical surgical instruments) may exceed 80 usd, depending on material utilization and processing time.

Post-Processing Costs: Anodizing, electroless nickel plating, etc., increase total costs by 15%-30%, while basic processing such as sandblasting has lower costs (silicon sand approximately 4-8 usd/piece). For ultra-complex structures or ultra-large batch requirements, CNC may be replaced by 3D printing or injection molding, but the design flexibility and precision advantages of the prototyping stage remain significant.