Prototype CNC machining has become one of the most essential methods for turning early design concepts into accurate, functional physical parts. With fast turnaround, multi-material compatibility, and exceptional dimensional precision, it enables engineers and product designers to validate geometry, test performance, and move quickly toward mass production.

Why Prototype CNC Machining Is Essential in Modern Product Development

Prototype CNC machining provides designers with a reliable way to create functional test parts before committing to expensive tooling or molds. Compared to other manufacturing methods, CNC machining offers superior accuracy, smoother surfaces, and consistent material performance.

Benefits of CNC Machining Prototyping

The growing demand for cnc machining prototyping comes from the need for:

- High dimensional accuracy

- Fully functional prototypes

- Material properties identical to final production parts

- Fast engineering iteration cycles

This makes prototype CNC processes ideal for industries such as aerospace, medical devices, automotive systems, robotics, energy equipment, and consumer electronics.

From Design to Prototype in Days

Because CNC machining does not require molds, engineers can quickly modify designs, upload updated CAD files, and produce improved prototypes within days. This flexibility is the reason many companies rely on supply cnc machining prototypes when developing their new products.

Material Options for Prototype CNC Machining

One of the major strengths of prototype cnc machining is its compatibility with a wide range of metals and plastics. Choosing the right material ensures structural strength, stability, and test validity.

Metal Materials for CNC Machining Prototypes

Below are the most commonly used metals for early-stage product verification.

Aluminum for Prototype CNC Machining

Aluminum cnc machining prototypes are popular due to:

- Lightweight strength

- Excellent machinability

- High thermal stability

- Cost-effective prototyping

Aluminum grades such as 6061, 5052, and 7075 are widely used in housings, brackets, mechanical parts, and lightweight structural components.

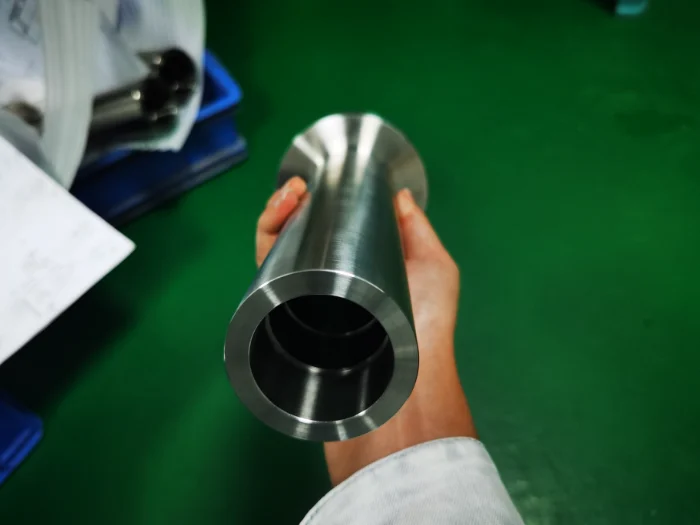

Stainless Steel

Stainless steel provides high strength, corrosion resistance, and reliability—ideal for mechanical assemblies, wearable hardware, medical fixtures, and high-load components.

Brass and Copper

These metals offer superior conductivity and are often used in electrical components, precision connectors, and thermal-transfer parts.

Plastic Materials for CNC Prototype Machining

Many prototype projects rely on plastics due to their stability, low weight, and affordability. CNC machining supports a large variety of engineering-grade plastics.

POM/Delrin

Known for its low friction and high stiffness, ideal for gears, movement mechanisms, and structural guides.

ABS

Strong, lightweight, cost-efficient, and suitable for housings, fixtures, and functional components.

Polycarbonate (PC)

Transparent, highly impact-resistant, and machinable—perfect for lenses, covers, and visualization prototypes.

PEEK

Advanced high-performance plastic used in medical, aerospace, and high-temperature applications.

These options demonstrate the flexibility provided by cnc plastic machining prototype solutions.

Applications of Prototype CNC Machining Across Industries

Electronics & Consumer Products

- Device housings

- Button components

- Internal structure frames

Medical Devices

- Surgical instrument prototypes

- Diagnostic housing parts

- Precision testing fixtures

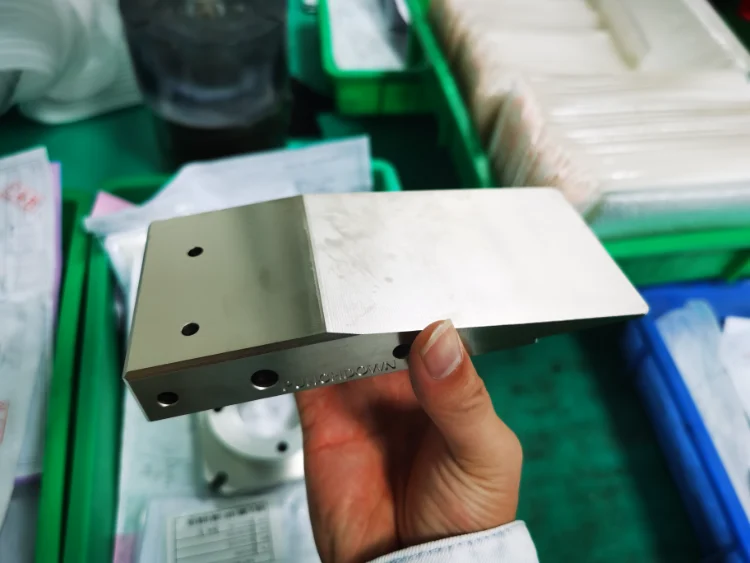

Automotive and Aerospace

- Metal brackets

- Fluid system connectors

- Structural evaluation components

Robotics and Automation

- Gear prototypes

- Positioning blocks

- Customized mechanical components

Prototype CNC machining is essential whenever real mechanical function must be validated before production.

Advantages of Using Prototype CNC Machining for Early Development

High Accuracy and Tight Tolerance

CNC machining provides the precision required to validate assembly, function, and fit during early testing.

Fast Iteration Cycles

Design can change rapidly, and CNC machining supports quick updates without tooling limitations.

Multi-Material Compatibility

Both plastics and metals can be machined under the same manufacturing process.

Keeps Design Intent Consistent

Prototypes produced with CNC machining behave almost identically to the final production parts.

Ideal for Functional Testing

Prototype CNC parts can be used for:

- Structural load tests

- Fatigue performance evaluation

- Assembly and movement testing

How Companies Supply CNC Machining Prototypes at Scale

A qualified manufacturer offering supply cnc machining prototypes must support:

- Fast quoting

- Multi-axis machining

- Accurate tolerance control

- Material consistency

- High repeatability

- Scalable production from 1 piece to hundreds

By combining engineering analysis and optimized machining parameters, prototype CNC machining ensures each part meets its testing requirements.

Aluminum CNC Machining Prototypes for Lightweight Industries

Because weight is a major concern for aerospace, automotive, and electronics, aluminum cnc machining prototypes are widely used during design verification.

Benefits of Aluminum Prototype Parts

- Strong but lightweight

- Smooth and stable surfaces

- Highly consistent internal structure

- Suitable for coating, anodizing, or polishing

- Useful for heat-dissipating components

Aluminum prototypes help engineers validate both mechanical and thermal factors before moving to mass production.

Request Prototype CNC Machining Quotes — Contact Weldo

A dependable manufacturing partner is critical for achieving reliable prototype quality. As an experienced provider of prototype cnc machining, Weldo offers precision machining for both metal and plastic prototypes, fast turnaround, and engineering feedback to improve manufacturability. Whether you need housing prototypes, mechanical test parts, functional assemblies, or structural verification samples, Weldo can support your needs from concept to production.

Contact Weldo today for accurate pricing, technical advice, and professional guidance on any prototype CNC machining project.

FAQ of prototype cnc machining

What is prototype CNC machining used for?

It is used to create accurate, functional prototypes that validate product geometry, mechanical performance, and assembly design before mass production.

Which materials are suitable for prototype CNC machining?

Common materials include aluminum, stainless steel, brass, ABS, POM, PC, and PEEK, depending on strength, appearance, or heat resistance needs.

How fast can CNC machining produce prototypes?

Most prototypes can be produced within 2–5 days depending on part complexity, quantity, and finishing requirements.

Why choose CNC machining prototyping over 3D printing?

CNC machining offers better accuracy, stronger materials, smoother surfaces, and prototypes that closely match final production performance.