Radius and Chamfer are two fundamental edge treatments in mechanical design and CNC machining. Although they may appear simple, proper use of Radius or Chamfer directly affects part strength, manufacturability, assembly efficiency, safety, and cost. This article explains what Radius and Chamfer mean in engineering, how Fillet and Chamfered edge features function, and how designers and buyers can apply them correctly in CNC machining projects.

Why Radius and Chamfer Matter in CNC Machining

In CNC machining, sharp edges rarely serve a functional purpose. The correct application of Radius and Chamfer improves both part performance and manufacturing efficiency.

Key reasons to apply Radius Chamfer include:

- Reducing stress concentration

- Improving fatigue strength

- Enhancing assembly alignment

- Eliminating sharp edges for safety

- Reducing machining difficulty

For precision components, Radius and Chamfer are not cosmetic features—they are engineering necessities.

Understanding Radius in Mechanical Design

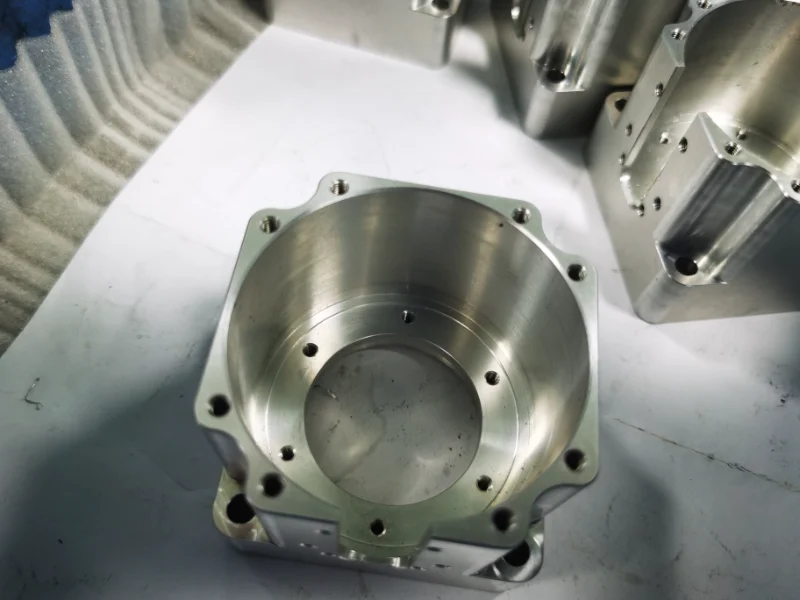

A Radius refers to a rounded edge or corner created by a circular arc. In CAD and engineering drawings, radius features are often referred to as Fillet.

Fillet and Radius Explained

- Radius (R): Dimensional definition (e.g., R2, R5)

- Fillet: Functional description of a rounded transition

Radius features can be applied as:

- Internal radius – inside corners

- External radius – outside edges

Both play a critical role in stress distribution and tool accessibility.

Internal Radius and External Radius: Functional Differences

Internal Radius

An Internal radius is applied to inner corners, pockets, and cavities.

Benefits:

- Reduces stress concentration

- Prevents crack initiation

- Matches CNC cutter geometry

In CNC machining, zero internal radius is impossible. Proper Radius or Chamfer planning avoids tool interference and unnecessary cost.

External Radius

An External radius smooths outer edges and transitions.

Benefits:

- Improves handling safety

- Enhances fatigue resistance

- Improves part appearance

External radius features are common on load-bearing and structural components.

Chamfer Explained: Purpose and Function

A Chamfer is a flat, angled surface applied to an edge, commonly at 45 degrees. In engineering documentation, it is often labeled as a Chamfered edge.

Common Chamfer Types

- C0.5, C1 (standard chamfer)

- 1 × 45° chamfer

- Custom angle chamfers

Compared to Radius and Chamfer alternatives, chamfers are simpler and faster to machine.

Radius and Chamfer: Key Differences in Engineering Use

Although they both modify edges, their functions differ.

| Feature | Radius / Fillet | Chamfer |

|---|---|---|

| Shape | Rounded arc | Flat angled surface |

| Stress reduction | Excellent | Limited |

| Assembly aid | Moderate | Excellent |

| Machining cost | Slightly higher | Lower |

| Typical use | Structural areas | Holes, edges, entries |

Understanding these differences helps engineers choose the correct Radius and Chamfer strategy.

Radius and Chamfer Impact on CNC Machining Cost

From a manufacturing perspective, Radius and Chamfer directly affect machining efficiency.

Radius Effects

- Requires specific cutter radii

- May need multiple tool passes

- Improves tool life by reducing chatter

Chamfer Effects

- Fast single-pass operation

- Low tooling cost

- Minimal cycle time impact

Optimizing Radius Chamfer selection can significantly reduce CNC machining cost without compromising function.

Design Guidelines for Radius and Chamfer in CNC Parts

Proper design standards improve consistency and manufacturability.

Recommended Radius Guidelines

- Internal radius ≥ cutter radius

- Avoid extremely small fillets (e.g., R0.1)

- Standardize radius values where possible

Recommended Chamfer Guidelines

- Use chamfered edge for assembly holes

- Apply default chamfer (C0.5 or C1)

- Avoid over-specifying chamfer angles

Following these rules ensures predictable Radius and Chamfer results.

Common Radius and Chamfer Design Mistakes

Improper use of Chamfer and Radius can increase cost and lead time.

Common mistakes include:

- Sharp internal corners with no radius

- Over-tight radius tolerances

- Using chamfer where stress relief is required

- Inconsistent edge treatment specifications

Clear Chamfer and Radius definitions prevent misinterpretation between designers and CNC suppliers.

Radius and Chamfer in High-Performance Materials

In materials such as stainless steel, titanium, Inconel, or Hastelloy, Radius or Chamfer become even more critical.

Benefits include:

- Reduced crack propagation

- Improved fatigue resistance

- Better machining stability

Weldo Machining frequently optimizes Radius and Chamfer features for difficult-to-machine alloys.

How CNC Suppliers Interpret Radius and Chamfer

A professional CNC supplier treats Radius + Chamfer as functional design elements, not default features.

At Weldo Machining:

- Internal radius is aligned with tooling capability

- Chamfered edge features are applied consistently

- Edge treatments are reviewed during DFM analysis

This ensures parts meet both performance and cost expectations.

Why Radius and Chamfer Improve Part Reliability

Well-designed Radius + Chamfer features contribute directly to part longevity.

Key reliability improvements:

- Lower stress concentration

- Reduced wear and fatigue

- Improved assembly repeatability

- Safer handling and operation

In mission-critical components, Chamfer and Radius decisions can influence long-term performance.

Conclusion: Applying Radius and Chamfer Correctly in CNC Machining

Chamfer and Radius are essential design features that influence strength, manufacturability, and cost. By understanding how Fillet, Internal radius, External radius, and Chamfered edge features function, engineers and buyers can avoid common design pitfalls and improve part quality. If you need expert guidance on applying Radius and Chamfer in CNC machining projects, contact Weldo Machining for professional support and competitive quotations.