Internal grinding

Our precision internal grinding services deliver IT5-grade accuracy (±0.001mm) and Ra 0.2μm surface finish for critical components in aerospace, automotive, and medical industries. Contact us now for customized machining solutions and receive a detailed quote within 24 hours.

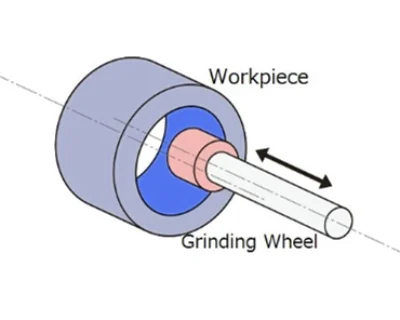

What is Internal Grinding ?

Internal Grinding is a composite process that simultaneously covers the finishing of both internal bores (inner circles) and outer cylindrical surfaces. By integrating specialized grinding wheels with high-precision control systems, it enables simultaneous dimensional control of both internal and external features on shafts, sleeves, mating surfaces, and similar components. This technology finds extensive application in industries such as hydraulic components, transmission systems, precision instruments, and energy equipment.

Materials suitable for internal grinding

Our internal grinding services meet the precision machining demands of over 80 types of metallic and non-metallic materials, encompassing diverse substances such as high-hardness alloys, brittle ceramics, lightweight non-ferrous metals, and engineering plastics. We tailor optimal material solutions and machining processes based on your part’s functional requirements (e.g., wear resistance, corrosion resistance), operating environment (e.g., high temperature, high pressure, corrosive media), cost control objectives, and surface quality specifications (e.g., surface roughness, roundness accuracy).

Metal material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

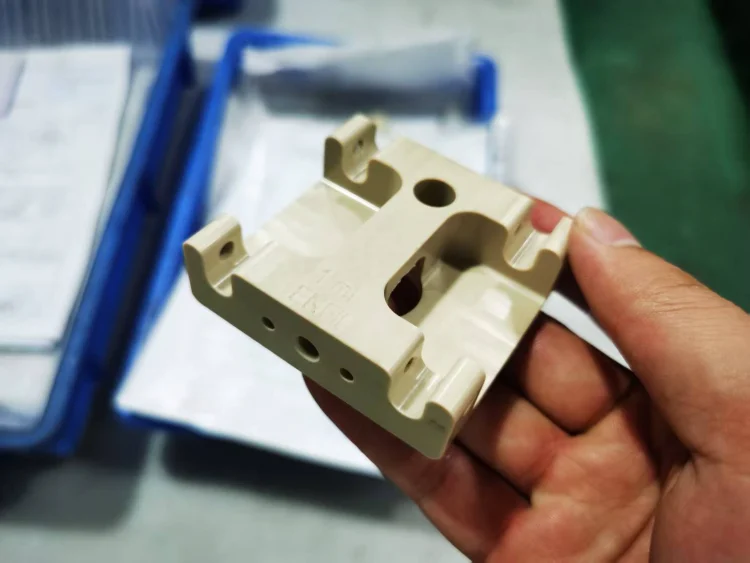

Plastic material :

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

Internal Grinding Capabilities

| Item | Specification |

|---|---|

| Roundness | ≤0.001mm (precision grade), ≤0.005mm (medium precision grade) |

| Cylindricity | ≤0.002mm/m (precision grade) |

| Surface Roughness | Ra 0.025μm (mirror grinding) ~ Ra 3.2μm (rough grinding) |

| Maximum Machining Diameter | ≤500mm (external) / ≤300mm (internal) |

| Maximum Machining Length | ≤2000mm |

| Minimum Machining Diameter | ≥0.5mm (external) / ≥2mm (internal) |

| Average Delivery Cycle | 5-7 days for precision parts, 3-5 days for regular parts |

| Process Capability Index | CPK≥1.33 (key dimensions) |

Guide to Internal Grinding

Grinding Wheel Selection Recommendations

| WORKPIECE MATERIAL | RECOMMENDED ABRASIVE | CHARACTERISTICS |

|---|---|---|

| Carbon steel, alloy steel | White corundum | High hardness, low heat generation, suitable for precision grinding |

| Stainless steel/titanium alloy | Cubic boron nitride | Good thermal stability, wear resistance is 100 times that of corundum |

| Aluminum alloy/brass | Green silicon carbide | High sharpness, avoids chip clogging |

| Ceramics/glass | Diamond | Superhard abrasive, suitable for hard and brittle materials |

Coarse grinding (Ra 1.6-3.2μm): 24#-60# grit size, soft grade (G-J) grinding wheel

Precision grinding (Ra 0.4-0.8μm): 80#-120# grit size, medium grade (K-M) grinding wheel

Super-precision grinding (Ra≤0.2μm): 150#-240# grit size, hard grade (N-P) grinding wheel

Processing Parameters for Common Workpiece Materials

Appropriate processing parameters are essential for achieving stable quality, dimensional accuracy, and consistent surface finish. The following parameters apply to both external grinding and internal grinding, covering key factors such as grinding wheel speed, feed speed, grinding depth, cooling method, and surface roughness.

The tables below provide recommended grinding parameters for metallic and non-metallic workpiece materials.

| MATERIAL | GRINDING WHEEL SPEED (M/S) | FEED SPEED (MM/MIN) | GRINDING DEPTH (MM) | COOLING METHOD |

|---|---|---|---|---|

| 45# steel | 30 – 35 | 100 – 150 | 0.05 – 0.1 | Emulsion high – pressure spraying |

| 304 stainless steel | 25 – 30 | 80 – 120 | 0.03 – 0.08 | Extreme – pressure cutting fluid + internal cooling |

| 7075 aluminum alloy | 20 – 25 | 150 – 200 | 0.1 – 0.2 | Kerosene spray cooling |

| NON – METALLIC MATERIAL | GRINDING WHEEL TYPE | FEED SPEED (MM/MIN) | SURFACE ROUGHNESS TARGET |

|---|---|---|---|

| POM | Atmospheric pore resin grinding wheel | 60 – 100 | Ra 0.8μm |

| PEEK | CBN grinding wheel | 40 – 60 | Ra 0.4μm |

| GFRP | Carbonized silicon grinding wheel | 80 – 120 | Ra 1.6μm |

Advantage Of Internal Grinding

High Precision Machining

Internal and external grinding achieves dimensional accuracies of ±0.001mm and roundness tolerances ≤0.0005mm, making it ideal for components with strict geometric and dimensional requirements, such as aerospace engine shafts and hydraulic valve cores.Superior Surface Quality

Through precision grinding processes, surface roughness can reach below Ra0.04μm, with ultra-precision grinding achieving mirror-like finishes as fine as Ra0.01μm. This meets demanding standards for optical components, mold cavities, and other high-surface-quality applications.Broad Material Compatibility

The process supports a wide range of materials, including metals (e.g., stainless steel, titanium alloys, hardened steel), non-metals (e.g., ceramics, glass, engineering plastics), and composite materials, covering hard, brittle, and soft properties.High Efficiency

CNC internal and external grinding machines enable continuous, stable machining. Combined with high-speed grinding technologies (e.g., CBN wheels), they significantly boost productivity and shorten cycle times.Process Flexibility

The method integrates rough, semi-finish, finish, and ultra-finish grinding in a single setup. Grinding parameters (e.g., feed rate, wheel speed) can be flexibly adjusted to accommodate varying batch sizes and part complexities.

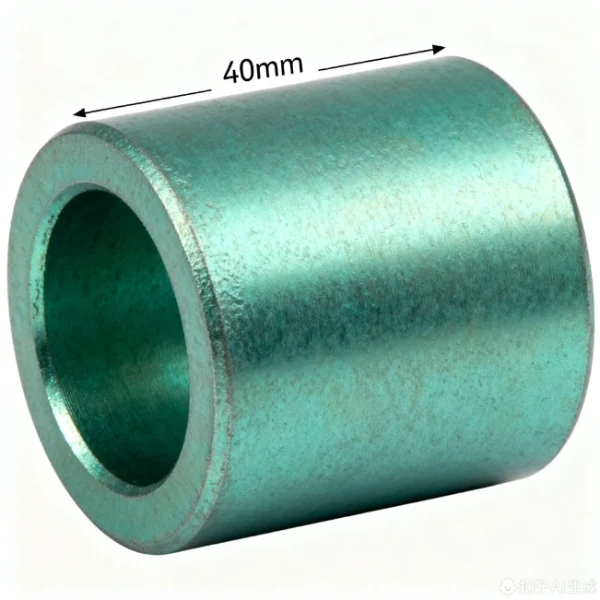

Application Fields for Internal Grinding

1.Aerospace

Typical Components: Turbine shafts, engine blades, landing gear struts, navigation system precision shafts.

Requirements: Withstands high temperatures, pressures, and rotational speeds, demanding exceptional material strength, wear resistance, and dimensional accuracy.

2.Automotive Manufacturing

Typical Components: Crankshafts, camshafts, transmission gears, hydraulic cylinder blocks, steering system bushings.

Requirements: High-volume production balancing efficiency and surface quality to ensure durability and reliability.

3.Mold and Die Making

Typical Components: Plastic mold cores/cavities, stamping die guide posts/bushings, die-casting mold bores.

Requirements: Demands high precision and low surface roughness to reduce mold wear and enhance product forming quality.

4.Medical Devices

Typical Components: Artificial joints (hip/knee), surgical instruments (drills, mills), implant bores.

Requirements: Must meet biocompatibility, corrosion resistance, and ultra-precision standards to ensure safety and longevity.

FAQ of internal grinding

What factors affect the surface roughness in internal - external cylindrical grinding, and how to adjust them?

Several factors influence surface roughness. The grinding wheel’s grit size is a key factor. A finer grit size generally produces a smoother surface as it can remove smaller amounts of material per pass. However, it may also result in a slower material-removal rate. The workpiece material also plays a role. Softer materials are more likely to be smear-ground, potentially leading to a rougher surface if not properly managed. To adjust surface roughness, you can change the grinding wheel to one with a different grit size. For example, if a smoother surface is required, switch to a grinding wheel with a finer grit. Additionally, optimizing the grinding parameters such as the feed speed and grinding depth can help. A slower feed speed and a smaller grinding depth usually contribute to a better surface finish.

How to choose the appropriate grinding wheel for internal - external cylindrical grinding?

When selecting a grinding wheel for external cylindrical grinding, factors such as the workpiece material, hardness, and the required surface finish should be considered. For hard-material workpieces like hardened steel, a cubic boron nitride (CBN) grinding wheel is often a good choice due to its high hardness and wear resistance. For softer materials, a corundum grinding wheel may be more suitable. For internal cylindrical grinding, the size of the inner hole is crucial. The grinding wheel must be small enough to enter the hole and have sufficient strength for effective grinding. For small-diameter inner holes, a thin and small-sized grinding wheel is required.

What are the common surface defects that may occur during internal - external cylindrical grinding and how to prevent them?

Common surface defects include scratches, burns, and chatter marks. Scratches can be caused by impurities on the grinding wheel surface or improper feeding. Prevent scratches by regularly dressing the grinding wheel and ensuring stable feed speed. Burns result from excessive grinding heat; use effective cooling methods like high-pressure coolant spraying and control grinding parameters. Chatter marks may result from unbalanced grinding wheels or poor workpiece clamping; balance the grinding wheel and improve clamping methods.

How to control the dimensional accuracy during internal - external cylindrical grinding?

Dimensional accuracy is controlled through precise measurement using instruments like micrometers. Optimize grinding parameters (wheel speed, feed speed, grinding depth) based on material and accuracy requirements. For high precision, use smaller grinding depths and slower feed speeds. Ensure machine stability through regular maintenance and calibration to reduce vibrations.

What are the advantages of using CNC technology in internal - external cylindrical grinding?

CNC technology enables high-precision, consistent results through accurate control of wheel and workpiece movement. It improves production efficiency via automated operations and continuous grinding processes. CNC machines store multiple programs, allowing easy switching between workpiece types and grinding requirements, providing flexibility in diverse manufacturing environments.