Other Manufacturing Services

Overview

Our “Other Manufacturing Services” provide flexible, cost-effective production options beyond CNC machining — including aluminum extrusion, sheet metal fabrication, and 3D printing. These complementary capabilities help you build complex parts, optimize cost, and accelerate prototyping or production.

Tolerance: Up to 0.005 inch.

Material: Engineer plastic,metal,polymer.

Application:Aerospace,automotive,medical device,Consumer electronics,new energy.

Delivery time: 1-10 days

Price: 5-200 usd/PCs

MOQ: From prototype to small batch(mass production)

What Are Our Other Manufacturing Services?

This category covers three core custom-part production methods used across automotive, electronics, consumer products, industrial equipment, and prototyping applications:

Aluminum Extrusion – Ideal for long, lightweight, durable profiles

Sheet Metal Fabrication – Perfect for enclosures, brackets, housings, and structural parts

3D Printing (Additive Manufacturing) – Best for rapid prototyping, complex geometries, and small-batch parts

These services complement machining, molding, and other core processes to give customers a complete manufacturing ecosystem.

Aluminum Extrusion Services

Custom Profiles & Structural Components

Aluminum extrusion produces continuous profiles with excellent strength-to-weight performance. It is widely used in frames, heatsinks, rails, lighting systems, and industrial structures.

Capabilities include:

Custom die extrusion

Post-machining & CNC finishing

Cutting, drilling, tapping

Surface finishing (anodizing, powder coating)

This process delivers consistent dimensional stability and high-volume production efficiency.

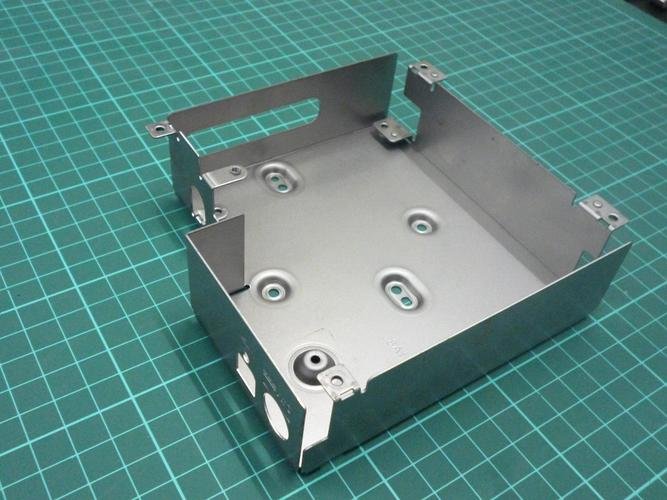

Sheet Metal Fabrication Services

Precision-Formed Metal Components

Sheet metal manufacturing transforms steel, aluminum, and stainless materials into accurate, durable parts through bending, cutting, stamping, and welding.

Capabilities include:

Laser cutting, turret punching

CNC bending & forming

MIG/TIG welding

Deburring, grinding, surface finishing

Assembly and hardware integration

Sheet metal is ideal for enclosures, automotive brackets, industrial housings, and structural components.

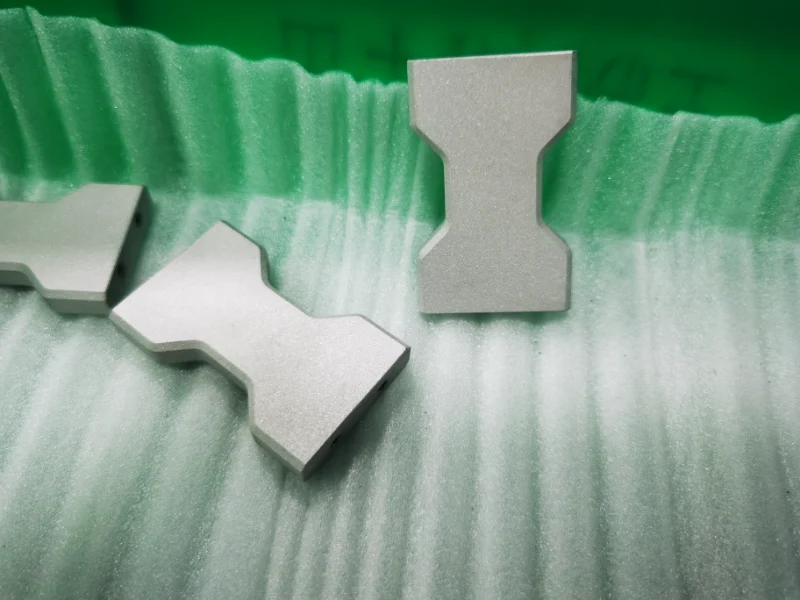

3D Printing Services

Rapid Prototyping & Complex Geometry Solutions

3D printing enables fast turnaround and design freedom unmatched by subtractive processes.

Supported technologies:

FDM、SLA、SLS、MJF

Material options:

Nylon / PA12、Resin、ABS-like materials、Flexible TPU

3D printing reduces development time and makes small-batch custom parts cost-effective.

Why Choose Our Other Services?

Integrated Production Ecosystem

All three processes—extrusion, sheet metal, and additive manufacturing—are managed within one manufacturing workflow, reducing complexity and improving project efficiency.

Faster Development Cycles

From rapid prototypes to validated production parts, our services shorten lead times and accelerate product launch.

Flexible Low-Volume & Scalable Production

Whether you need a single prototype or thousands of components, our production network adapts to your volume and budget.

Quality & Material Versatility

With standardized processes and experienced engineering support, we ensure consistent quality regardless of material or geometry.

Typical Applications Across Industries

Consumer product enclosures & frames

Automotive brackets, lighting parts, EV components

Machinery structures and guide rails

Electronic housings, heatsinks, mounting plates

Rapid prototypes for concept validation

Surface finish for other manufactured parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various manufactured parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

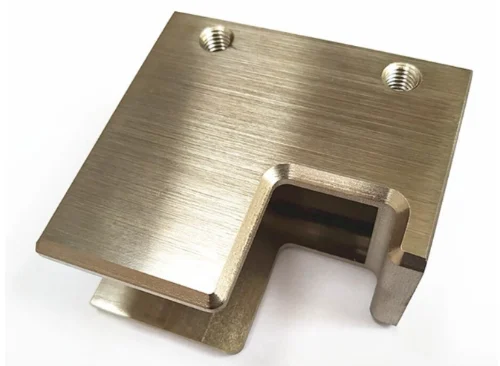

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

FAQ of other service manufacturing

What types of projects are best suited for aluminum extrusion?

Aluminum extrusion is ideal for long, lightweight profiles such as frames, rails, heatsinks, and structural components.

Can sheet metal fabrication support complex geometric shapes?

Yes, with CNC cutting and multi-axis bending, sheet metal can create detailed and highly precise geometries.

Do you offer finishing services for aluminum and sheet metal parts?

Yes, options include anodizing, powder coating, plating, polishing, brushing, and painting.