Fast wire EDM

Overview:

Looking to efficiently achieve high-precision part machining? Choose our Fast Wire EDM ! With advanced equipment and specialized expertise, we can process complex shapes while ensuring precision and surface finish. Enjoy short lead times and cost-effective solutions. Ideal for molds, precision components, and more—contact us today for a customized plan!

Tolerance: 0.005-0.01 mm

MOQ:1-500 PCs

Price: 10-50 USD/PCs

Fast wire edm machining Material

Fast wire EDM is suitable for machining electrically conductive materials such as carbon steel, alloy steel, stainless steel, copper, and aluminum, and is widely used for tooling, fixtures, and general industrial parts.

Material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

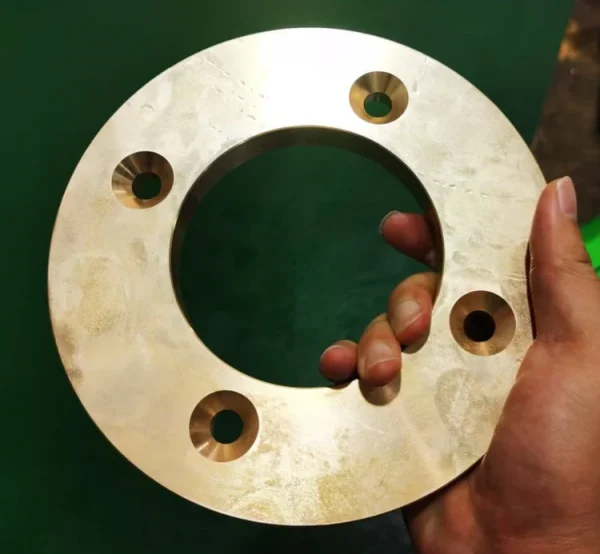

Bronze

Bronze is a copper–tin alloy with good fluidity and corrosion resistance, widely used for bearings, gears, valves, and marine components such as propellers and pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Steel is an iron–carbon alloy with adjustable strength, toughness, and wear resistance, widely used for bolts, shafts, gears, cutting tools, and engine components.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium is a lightweight metal with low cutting force, excellent thermal conductivity, and a high strength-to-weight ratio. Its superior vibration damping makes it well suited for aerospace, automotive, and electronics applications.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

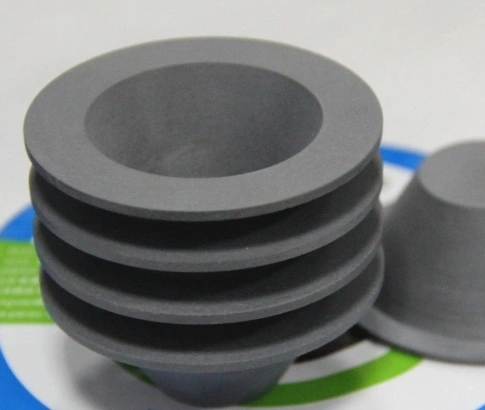

Graphite

Graphite conductivity is used for precision molding to avoid dust pollution caused by machining. It is mainly used for electrode manufacturing and EDM molds.

Color : Black.

Surface finish : Mechanical cutting, pickling, electrolytic treatment, coating, polishing, EDM surface strengthening.

Delivery time : 3-5 days

Conductive ceramic part

Conductive ceramics are used in aerospace and other fields due to their high hardness, brittleness, and excellent chemical stability, but they are difficult to process. Using pulsed discharge to generate high temperatures (approximately 10,000°C) to partially melt the ceramic allows for contactless processing, avoiding stress concentration and cracking caused by mechanical processing.

Type : Oxide/non-oxide conductive ceramics, composite conductive ceramics

Color : white, gold, pink black, etc.

Delivery time : 3-5 days

Fast wire edm machining capability

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.01 ~ ±0.02 mm |

| Repeat Positioning Accuracy | ≤ 0.005 mm |

| Single Cut Surface Finish | Ra 2.5 ~ 3.2 μm |

| Multiple Cuts Surface Finish | Ra 1.6 ~ 0.8 μm |

| Process Optimization | Emulsion (concentration 8–10%) + Ø0.18 mm molybdenum wire, Ra value can be reduced by ~30% |

| Conventional Material Cutting Rate | 120 ~ 180 mm²/min |

| High Hardness Material Cutting Rate | 80 ~ 100 mm²/min |

| Maximum Efficiency | 200 mm²/min |

| Minimum Corner Radius | R 0.05 mm |

| Maximum Taper | ±3° / 100 mm |

| Minimum Slot Width | 0.23 mm |

Guide of fast wire EDM machining

Proper wire selection and routine maintenance are essential for stable wire EDM machining. The following tables summarize recommended wire parameters, common wire breakage causes, and maintenance guidelines.

Electrode Wire Selection

| Processing Type | Wire Diameter (mm) | Tension (N) | Wire Feed Speed (m/s) |

|---|---|---|---|

| Rough Processing (Efficiency Priority) | 0.25 | 10–15 | 10–12 |

| Precision Processing (Accuracy Priority) | 0.18 | 8–10 | 6–8 |

Causes of Wire Breakage and Countermeasures

| Fault Phenomenon | Possible Cause | Solution |

|---|---|---|

| Sudden wire breakage during machining | Excessive molybdenum wire tension (>15 N) | Adjust tension to 8–12 N; replace with new wire (recommended every 8 hours) |

| Wire breakage during direction change | Guide wheel bearing wear | Replace guide wheel assembly (recommended every 3 months) |

| Wire breakage in thick workpiece area | Insufficient working fluid concentration (<8%) | Replenish emulsion to 10% concentration; clean filter screen |

Regular Maintenance Schedule

| Maintenance Cycle | Item | Standard Requirement |

|---|---|---|

| Weekly | X/Y-axis ball screw lubrication | Apply lithium grease; manually lubricate throughout the stroke |

| Monthly | Guide wheel runout detection | Radial runout ≤ 0.003 mm; replace bearing if exceeding tolerance |

| Quarterly | Working fluid replacement | Fully drain old fluid and clean inner wall of the tank |

FAQ of fast wire EDM machining

What is fast wire cutting (fast WEDM), and how does it work?

Fast Wire Electrical Discharge Machining (Fast WEDM) uses a rapidly moving thin wire as an electrode to cut conductive materials through controlled electrical sparks. The wire erodes material without direct contact, enabling precise cutting of complex shapes.

What materials can be processed using fast wire cutting?

Suitable for conductive materials including steel, aluminum alloys, copper, tungsten carbide, and other electrically conductive metals. Non-conductive materials cannot be processed.

What are the advantages of fast wire cutting compared to conventional machining?

Advantages include high precision (±0.01~±0.02mm), ability to cut complex shapes, no mechanical stress, and cost-effectiveness for low-volume/custom parts.

What factors affect cutting speed and surface quality?

wire tension/feed speed, pulse parameters (energy/duration), workpiece material/thickness, and dielectric fluid condition.

How often should maintenance be performed on fast wire cutting machines?

Clean tanks, check wire tension. Weekly: Lubricate screws. Monthly: Check guide wheel runout. Quarterly: Replace dielectric fluid.