Stainless steel CNC machining prototype is an essential process for creating high-precision parts used in various industries. This technology offers remarkable versatility and is widely used for producing prototypes, custom parts, and products that require exact dimensions and high durability. In this blog, we’ll explore the different types of stainless steel used for CNC machining, the industries where they’re applied, post-processing options, and how to lower the costs of prototyping and mass production.

What is Stainless Steel CNC Machining?

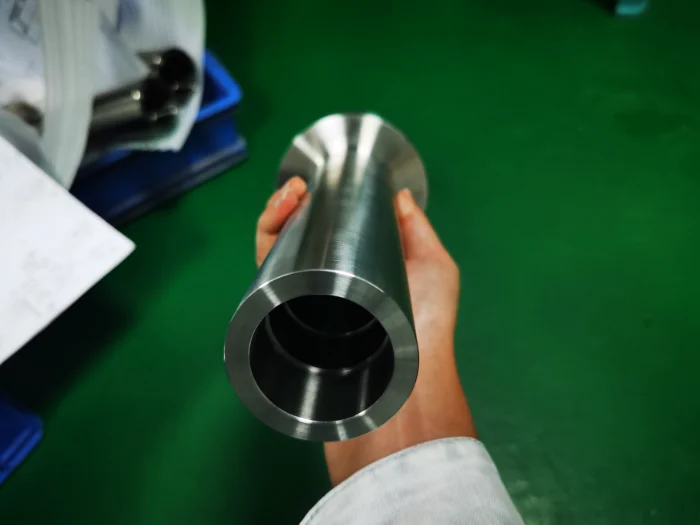

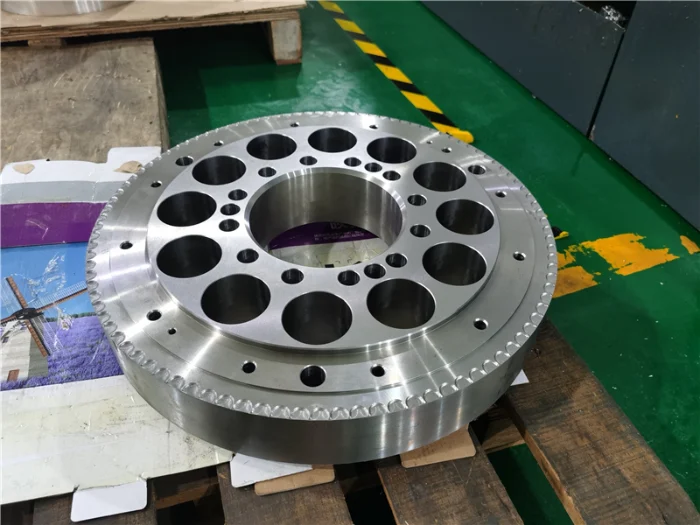

Stainless steel CNC machining refers to the use of computer-controlled machinery to fabricate stainless steel parts based on precise specifications. CNC machines are capable of creating complex geometries and intricate designs, making them perfect for manufacturing stainless steel prototypes and parts that require tight tolerances.

Types of Stainless Steel Used in CNC Machining

When selecting stainless steel for CNC machining, several types and grades are available. The most common include:

- 304 Stainless Steel

- The most commonly used grade, known for excellent corrosion resistance and weldability.

- Ideal for general-purpose applications such as food processing equipment and medical parts.

- 316 Stainless Steel

- Offers superior resistance to corrosion, especially in harsher environments like marine applications or chemical processing.

- Often used for high-strength components in the aerospace and medical industries.

- 17-4 PH Stainless Steel

- A precipitation-hardening steel known for its high strength and hardness.

- Used in high-performance applications like aerospace, valves, and gear systems.

- 410 Stainless Steel

- A martensitic steel that offers high wear resistance and can be hardened by heat treatment.

- Commonly used for parts like cutting tools and industrial machinery.

- 420 Stainless Steel

- Known for its ability to be hardened for high wear resistance.

- Often used in tooling and medical device applications.

Common Industries and Applications for Stainless Steel CNC Machining

The versatility of stainless steel CNC machining makes it ideal for various industries. Some common applications include:

- Aerospace: Aircraft parts, engine components, and structural elements.

- Automotive: High-strength parts, exhaust components, and engine components.

- Medical: Surgical tools, implants, and medical devices.

- Food Processing: Food handling equipment, sterilization parts, and storage systems.

- Marine: Marine hardware, valves, and fittings.

Post-Processing Options for Stainless Steel CNC Machining

Post-processing refers to the additional finishing processes that can be applied to CNC machined parts to improve their surface appearance, strength, and overall functionality. Some common surface finishes techniques for stainless steel CNC machining include:

1. Polishing

- Improves the aesthetic quality of the part, creating a smooth, shiny surface.

- Often used for parts exposed to high visibility or for medical and food-grade components.

2. Passivation

- Enhances corrosion resistance by removing free iron from the surface of stainless steel, increasing durability.

- Particularly important for parts used in harsh environments or sensitive industries.

3. Anodizing

- Used mainly on aluminum but can be applied to stainless steel for color and additional corrosion protection.

- Ideal for decorative finishes and adding extra layers of protection to stainless steel.

4. Heat Treatment

- Used to modify the hardness and strength of stainless steel parts.

- Ideal for parts that need to withstand high pressures or wear.

Factors Affecting the Cost of Stainless Steel CNC Machining prototype

Several factors contribute to the cost of stainless steel CNC machining, including:

- Material Grade: High-grade stainless steels like 316 or 17-4 PH can be more expensive than 304 due to their superior properties.

- Part Complexity: More intricate designs and detailed features require specialized tooling, leading to higher machining costs.

- Batch Size: Larger production runs often result in a lower cost per part, as the setup and tool changes are amortized over more units.

- Tolerances and Finishes: Tight tolerances and advanced finishes increase machining time and require higher-skilled labor or more advanced equipment.

- Tooling and Setup Costs: Custom tooling or longer setup times can add significant costs, particularly for low-volume runs or prototypes.

How to Reduce Prototyping and Mass Production Costs

1. Optimize Design for Manufacturability (DFM)

The earlier the design incorporates DFM principles, the easier it is to reduce production costs. Simplifying part geometries, using standard sizes, and minimizing unnecessary features can drastically lower costs. Additionally, DFM ensures that parts are designed with machining constraints in mind, minimizing tooling changes and improving part orientation on the CNC machine.

2. Choose the Right Material

Choosing a more cost-effective stainless steel grade, such as 304 stainless steel, for less demanding applications can help reduce material costs. For parts requiring higher strength or corrosion resistance, opt for the appropriate material based on the application to prevent over-specifying.

3. Invest in Efficient Machinery

Upgrading to more efficient CNC machines can reduce processing times and increase throughput, leading to lower per-part costs, especially in high-volume production. Consider advanced multi-axis machines that offer greater precision and faster cycle times for complex parts.

4. Reduce the Number of Operations

Minimizing the number of machine setups or operations reduces production time and machine wear, which ultimately lowers overall costs. CNC milling or turning processes should be optimized to complete as much of the machining as possible in a single operation.

5. Batch Production vs. Prototyping

Prototyping often incurs higher costs due to lower volume, specialized tooling, and setup. However, for mass production, consider producing parts in larger batches to reduce setup costs and take advantage of economies of scale.

Get a Quote for Custom Stainless Steel CNC Machining

At Weldo Machining, we specialize in custom CNC aluminium machining for prototypes and mass production. Our team of experts ensures that your stainless steel CNC machining parts are designed for manufacturability and produced with precision at competitive prices. Contact us today for a detailed quote and to discuss your stainless steel CNC machining needs.

FAQ of stainless steel cnc machining prototype

How long does it take to produce a stainless steel prototype?

Prototypes can typically be completed in a few days to a week, depending on the part complexity and the number of operations required.

What factors affect the price of CNC machining?

Price is influenced by material type, part complexity, tolerances, batch size, post-processing needs, and tooling setup.

How can I reduce the cost of stainless steel CNC machining?

To reduce costs, simplify the design, use standard material grades, increase batch size, and optimize machining operations to minimize tool changes and setup time.