In today’s manufacturing landscape, industries rely heavily on stainless steel CNC machining services to produce high-strength, wear-resistant, and dimensionally stable components. Stainless steel is one of the most requested materials in CNC machining due to its durability, resistance to corrosion, and superior performance in harsh environments. Whether used in aerospace, automotive, medical devices, energy equipment, or industrial machinery, precision CNC machining ensures stainless steel parts meet exact design requirements.

This article explores the capabilities, benefits, and cost considerations of stainless steel machining.

Understanding the Value of Stainless Steel CNC Machining Services

When companies choose stainless steel CNC machining services, they expect high precision and reliable performance. Stainless steel alloys—including 303, 304, 316, 410, and 17-4PH—are known for their exceptional hardness, stability under high load, and corrosion resistance. CNC machining enhances these natural advantages by providing accurate cuts, tight tolerance control, and smooth surface finishes.

CNC machining allows manufacturers to convert CAD models into physical components with minimal deviation. This is crucial for industries where stainless steel parts must maintain performance under heat, pressure, chemical exposure, or heavy mechanical stress.

Advantages of Using CNC Machining Parts Stainless Steel

Strength and Durability Benefits

One of the primary reasons engineers prefer CNC machining parts stainless steel is the material’s ability to withstand harsh operating conditions. Stainless steel resists oxidation, deformation, and corrosion, making it ideal for structural, mechanical, and fluid-handling components.

Consistent Performance in Demanding Applications

Industries such as oil & gas, aerospace propulsion, and medical diagnostics require parts that can last for years without failure. Stainless steel maintains its mechanical integrity, and when processed through advanced CNC equipment, the resulting parts achieve:

- Tight dimensional accuracy

- Excellent fatigue resistance

- Low deformation during machining

- High wear resistance

These qualities ensure reliable function in applications where failure is not an option.

303 Stainless Steel CNC Machining for High-Efficiency Processing

Why 303 Stainless Steel Is Popular

Among all stainless steel grades, 303 stainless steel CNC machining is widely requested due to its superior machinability. The addition of sulfur improves cutting performance, reduces tool wear, and lowers machining time.

This makes 303 stainless steel ideal for:

- Fast-turnaround mechanical parts

- Complex geometries

- High-volume production

- Components requiring smooth surface finishes

Applications of 303 Stainless Steel Components

Typical parts produced via 303 stainless steel CNC machining include:

- Fittings and connectors

- Sensor housings

- Fasteners and sockets

- Gears and bushings

- Small precision mechanical parts

Its cutting efficiency helps manufacturers reduce cost without sacrificing mechanical strength.

Custom CNC Machining Stainless Steel for Specialized Components

Tailored Solutions for Unique Projects

Many industries require custom CNC machining stainless steel for components that cannot be mass-produced. Custom machining allows customers to specify:

- Unique shapes and geometry

- Non-standard tolerances

- High-precision internal channels

- Complex threading requirements

- Micro-machined details

These custom capabilities are necessary for medical implants, aerospace detectors, defense systems, semiconductor machinery, and prototype development.

Additional Services Supporting Customization

Custom stainless steel CNC machining may also include:

- Heat treatment

- Passivation

- Electro-polishing

- Grinding and surface finishing

- Assembly and inspection

These additional processes ensure the final product meets strict functional and cosmetic standards.

Common Stainless Steel Grades Used in CNC Machining

Different stainless steels offer different performance characteristics. Key grades include:

303 Stainless Steel

Best machinability, ideal for high-volume production.

304 Stainless Steel

General-purpose, excellent corrosion resistance.

316 Stainless Steel

Superior chemical resistance, ideal for marine and medical industries.

410 Stainless Steel

Hard and wear-resistant, suitable for tools and mechanical components.

17-4PH Stainless Steel

High strength and stability after heat treatment.

Choosing the right material significantly influences cost, machining speed, and part performance.

How Stainless Steel CNC Machining Services Work

Key Steps in the Machining Process

Stainless steel machining involves several structured stages:

Material Preparation

Stainless steel bars, plates, or billets are selected based on the design.

CNC Programming

Toolpaths are optimized to reduce heat, tool wear, and cycle time.

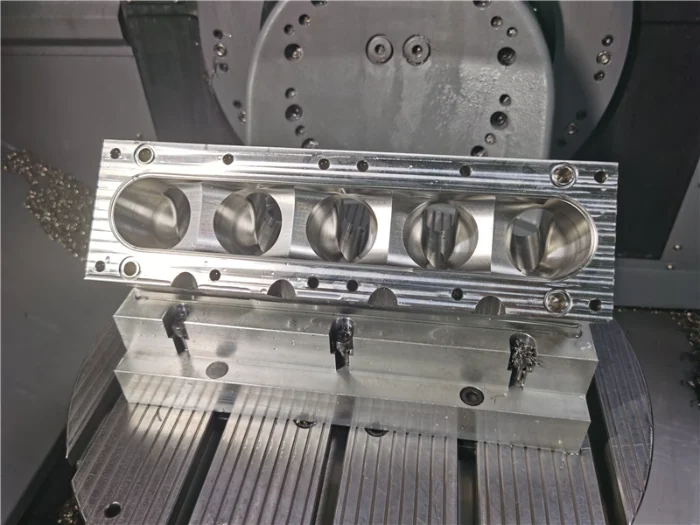

Rough Cutting and Milling

High-rigidity tools cut the general shape of the part.

Precision Finishing

Light cutting passes ensure tight tolerances and smooth surfaces.

Inspection & Quality Control

CMM (coordinate measuring machines) verify dimensional accuracy.

Surface finish

Polishing or passivation enhances corrosion resistance.

Tolerance Capabilities

High-end stainless steel CNC machining services can achieve tolerances as tight as ±0.005 mm depending on geometry and machine configuration.

Industries That Rely on Stainless Steel CNC Machining

Due to its strength and reliability, stainless steel is widely used in:

- Aerospace components

- Automotive powertrain parts

- Marine hardware

- Medical surgical tools

- Food processing equipment

- Electronic and sensor housings

- Energy and hydraulic systems

Meeting Strict Industry Standards

These applications require consistent precision and quality, which only advanced CNC machining can deliver.

Cost Factors Affecting Stainless Steel CNC Machining Services

Material Selection

Some materials, especially 316 or 17-4PH, are more difficult to machine and require additional tool wear management.

Geometry Complexity

Thin walls, deep channels, or multiple setups increase machining time.

Surface Finish Requirements

Polishing, grinding, or mirror finishing adds extra process steps.

Understanding these factors helps companies better estimate project budgets and timelines.

Conclusion: Why Stainless Steel CNC Machining Services Matter

As industries push for higher efficiency, reliability, and durability, the importance of stainless steel CNC machining services continues to grow. Whether producing CNC machining parts stainless steel, performing 303 stainless steel CNC machining, or developing high-end custom CNC machining stainless steel, choosing the right machining provider ensures precision, quality, and long-term performance.

Stainless steel remains one of the most versatile materials in modern manufacturing, and CNC machining unlocks its full potential for both standard and specialized applications.

FAQ of stainless steel cnc machining service

What industries benefit most from stainless steel CNC machining services?

Aerospace, medical devices, automotive, food processing, and industrial machinery rely heavily on stainless steel CNC parts for strength and corrosion resistance.

Is 303 stainless steel easier to machine than 304 or 316?

Yes. 303 stainless steel contains sulfur, which improves machinability and reduces tool wear, making it faster and more economical to machine.

Can stainless steel CNC machining achieve tight tolerances?

Absolutely. High-precision CNC machines can achieve tolerances as tight as ±0.005 mm depending on part geometry and grade of stainless steel.