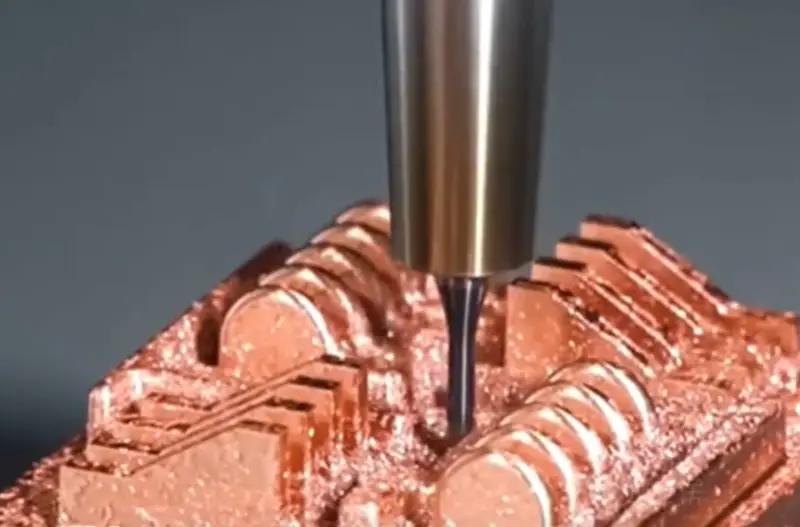

In modern manufacturing, brass components are widely used in industries such as automotive, electronics, medical, and aerospace due to their excellent corrosion resistance, good mechanical properties, and ease of machining. For many companies, choosing the right CNC machining supplier is key to ensuring product quality and production efficiency. With the rise of on-demand manufacturing and rapid prototyping technologies, many professional CNC machining suppliers around the world offer high-precision, fast-turnaround brass machining services. This article provides a detailed analysis of the Top 10 Brass CNC Machining Suppliers, helping you better understand the characteristics, advantages, and limitations of each company so that you can make an informed choice.

1. Protolabs

Establishment Time / Background

Protolabs, founded in 1999 in the United States, is a global rapid manufacturing supplier offering rapid prototyping and mass production parts, including CNC machining, 3D printing, injection molding, and sheet metal services.

Main Machining Capabilities

- CNC milling and turning (including 3-axis and 5-axis)

- Fast quoting system and real-time manufacturing analysis

- Accepts plastic and metal materials, including brass and other metals.

Other Information

Protolabs has multiple factories and a collaborative manufacturing network globally, serving industries such as medical, aerospace, and consumer electronics.

Advantages

✔ Rapid delivery, with shipment possible in as fast as 1 day

✔ Global services + digital quoting and analysis

✔ Suitable for rapid prototyping and small to medium batch production

Limitations

⚠ For extremely complex or oversized parts, Protolabs may rely on partner networks rather than its own capacity

⚠ Prices may be higher than traditional machining factories (especially for standard batches).

2. MSP Industries (USA)

Establishment Time / Background

MSP Industries began producing precision machined parts in 1948 and is a long-established CNC machining supplier in the United States.

Main Machining Capabilities

- CNC 5-axis, Swiss ultra-precision machining, multi-spindle machining

- Precision milling, turning, grinding, drilling, and tight tolerance control

- Can machine a variety of materials, including brass, aluminum, steel, etc.

Other Information

ISO 9001:2015 certified, offering broad industry services (automotive, defense, medical, HVAC, etc.).

Advantages

✔ Over 70 years of industry experience

✔ Strong high repeatability and high tolerance control

✔ Local production and fast response advantages

Limitations

⚠ Mainly serves heavy industry and large-volume needs, and may not be as flexible for small batch, precision projects as digital manufacturing platforms.

3. Fictiv

Establishment Time / Background

Fictiv is a digital manufacturing platform (similar to on-demand manufacturing markets) that provides CNC, injection molding, 3D printing, and other services.

Main Machining Capabilities

- CNC milling and turning

- Multiple material options, including brass, aluminum alloy, stainless steel, bronze, etc.

- Digital quoting, DFM analysis, and global supply network.

Other Information

Fictiv’s platform is ideal for engineering teams to carry out rapid prototyping and mass production deployments.

Advantages

✔ Digital experience allows for rapid pricing and order management

✔ Flexible supply network covering multiple regions

✔ Suitable for remote collaboration

Limitations

⚠ Does not directly produce, actual machining depends on partner suppliers

⚠ Control of industrial-grade repetitive batches is not as strong as in-house factories.

4. Weldo

Establishment Time / Background

Founded in 2012, Weldo operates its own factory industrial park providing CNC machining services, covering a range of materials including aluminum alloy, brass, bronze, stainless steel, alloy steel, and cast iron. They also support machining of over 20 types of engineering plastics (ABS, POM, PMMA, PEEK, PP, PC, PA, PTFE, fiberglass, carbon fiber, etc.), and support over 20 types of surface treatments, including anodizing, electroplating, sandblasting, engraving, and galvanizing.

Main Machining Capabilities

- CNC milling, turning, CNC grinding, drilling, and fast/slow wire EDM

- Parts precision up to 0.001″, large milling sizes up to 2000×1000×1000 mm.

Other Information

Services include injection molding, 3D printing, sheet metal, aluminum extrusion, and other manufacturing methods.

Advantages

✔ Covers a variety of machining methods and material processing

✔ Can handle large-size, precision machining

5. PCBWay

Establishment Time / Background

Founded in 2013–2014, PCBWay is a Chinese manufacturing platform that started with custom PCB processing and later expanded to CNC, 3D printing, and other services.

Main Machining Capabilities

- CNC milling and turning (3 to 5-axis)

- Supports machining of various metals, including brass

- One-stop services for PCB, PCBA, CNC, 3D printing, etc.

Other Information

PCBWay is popular for rapid prototyping and small batch manufacturing, while also offering quality control and global shipping support.

Advantages

✔ Integration of multiple manufacturing services (PCB + CNC + 3D printing)

✔ Ideal for electronic product developers and engineers

✔ Wide range of material options

Limitations

⚠ CNC is not the core business, less well-known compared to PCB/PCBA

⚠ May be more focused on prototyping rather than high-end manufacturing for extremely high-precision mechanical parts

6. Avanti Engineering

Avanti Engineering is a traditional American manufacturer with over 50 years of CNC experience.

Main Machining Capabilities

- CNC milling, turning, Swiss precision machining, multi-spindle machining

- Complex, tight-tolerance brass parts machining

- Suitable for prototyping, small batch, and high-volume production.

Other Information

ISO 9001:2015 certified with a rigorous process covering design evaluation to production support.

Advantages

✔ Deep industry experience and engineering support

✔ Specializes in tight tolerances and surface quality control

✔ Can handle complex geometries and medium to high-volume production

Limitations

⚠ Longer lead times compared to digital manufacturing platforms

⚠ Higher prices for low-volume orders due to brand value

7. McCormick Industries

Establishment Time / Background

McCormick Industries has been specializing in high-precision CNC machining since 1996, especially Swiss and precision parts.

Main Machining Capabilities

- Swiss precision machining (up to ±0.0001 inches)

- CNC turning, milling, and spindling

- Supports small, high-precision brass components.

Other Information

Extensive service to aerospace, medical, and industrial sectors, providing surface finishing and other value-added services.

Advantages

✔ Ultra-precision machining for critical industrial applications

✔ Experienced and suited for complex parts

✔ ISO certified with a strong quality system

Limitations

⚠ Not suitable for very large sizes or low tolerance applications compared to specialized 5-axis centers

8. The Federal Group USA (TFG)

Establishment Time / Background

The Federal Group was founded in 1980 and is a multi-process metal manufacturer (forging, casting, CNC, etc.).

Main Machining Capabilities

- Precision CNC milling, turning, and multi-axis machining (including brass CNC)

- Integration of forging, casting, and extrusion processes for complex product manufacturing.

Other Information

ISO 9001 certified, serving industries like construction, energy, and medical.

Advantages

✔ Process integration advantage (forging + casting + CNC)

✔ End-to-end manufacturing from raw material to finished products

✔ Strong capabilities for medium to high-volume parts

Limitations

⚠ CNC is just one of many business areas, possibly not as focused on precision as CNC-specialized suppliers.

9. DW Products, Inc.

Establishment Time / Background

DW Products has over 30 years of history, specializing in screw machining products and CNC parts.

Main Machining Capabilities

- CNC screw machining products

- CNC milling and turning services (through partner networks)

- Precision brass and other material parts.

Other Information

Services include prototyping to production-level parts, handling various materials.

Advantages

✔ Extensive experience in screw machining and CNC products

✔ Focused on standard mechanical part production

Limitations

⚠ Limited details available, and the website doesn’t provide extensive CNC brass machining capabilities

10. Xometry

Establishment Time / Background

Founded in 2013, Xometry is an on-demand manufacturing platform that connects customers with global suppliers.

Main Machining Capabilities

- CNC, 3D printing, injection molding, and other manufacturing methods

- Supports rapid quoting and production of brass machining parts

- Covers a global network of suppliers.

Other Information

AI-driven quoting and supply chain matching increase usability.

Advantages

✔ Global manufacturing network, fast and flexible

✔ Suitable for large batches and multi-region production

Limitations

⚠ Some processing is outsourced, and the quality may vary depending on suppliers

⚠ Mainly relies on platform matching, with process transparency dependent on the supply chain.

To help you make an informed decision, here is a summary comparison table of the advantages and disadvantages of major brass CNC machining suppliers. You can make the most suitable choice based on each supplier’s core strengths, suitable applications, and potential limitations.

| Supplier | Core Advantage | Suitable For | Limitations |

|---|---|---|---|

| Protolabs | Ultra-fast delivery + digital services | Rapid prototyping & small batches | Limited for extremely high precision or large parts |

| MSP Industries | Century-long experience + high repeatability | Industrial large volumes | Higher cost for small batch, precision projects |

| Fictiv | Digital quoting, flexible supply | Remote manufacturing collaboration | Does not produce in-house |

| Weldo | Multiple materials machining + surface treatments | Large-size/Multiple processes | |

| PCBWay | One-stop manufacturing integration | PCB and mid-low precision CNC | CNC is not the core business |

| Avanti Engineering | Deep industry experience | Tight tolerances & mid-high volume | Price & lead time |

| McCormick Industries | Swiss precision | Precision small parts | Few options for large parts |

| TFG USA | Multi-process integration | End-to-end manufacturing | CNC focus not as strong |

| DW Products | Screw machine products | Standard parts | Limited details available |

| Xometry | Global supply chain | Flexible, fast matching | Quality fluctuations from suppliers |

How to Choose the Right Machining Supplier

When selecting a brass CNC machining supplier, companies need to consider the following factors:

- Lead Time

For businesses with urgent time requirements, companies offering fast delivery services (like Protolabs, Fictiv, or Weldo) may be more suitable. - Machining Precision and Tolerances

For industries requiring high precision and tight tolerances, such as aerospace or medical, companies like McCormick Industries or Avanti Engineering, with strong experience in precision machining, may be ideal. - Batch Requirements

If small-batch production is required, choosing a digital manufacturing platform (like Fictiv, Weldo, or PCBWay) can provide more flexible services. For large-batch production, traditional manufacturers like Weldo may be more appropriate. - Material Selection and Technical Support

If various materials or additional technical support (such as surface treatments) are required, choosing a diversified manufacturing platform like PCBWay or TFG USA may be more suitable.

Recommendations Based on Regional Procurement Needs

- North American Market: Companies like Protolabs, MSP Industries, and McCormick Industries, which are based in the U.S., offer strong local support and fast response, making them ideal for businesses needing quick delivery and high-precision products.

- Asian Market: For businesses seeking low cost and flexible customization, companies like PCBWay and Weldo offer more comprehensive services at competitive prices.

- European Market: For customers with high-precision machining requirements, suppliers like Avanti Engineering and Xometry, which have a global presence and high-precision manufacturing capabilities, could be considered.

Considerations for Cooperation

- Clear Requirements: When communicating with suppliers, be sure to clearly articulate your specific requirements, including part dimensions, materials, machining precision, tolerance standards, and delivery timelines.

- Sign a Contract: Make sure to sign a clear contract before collaboration, specifying production standards, quality inspection processes, delivery timelines, and confidentiality agreements.

- Quality Control: Establish effective quality control processes with the supplier to ensure each part meets specifications. Consider obtaining regular samples or third-party inspection reports (with additional costs and time).

- Communication and Feedback: Maintain continuous communication with suppliers and provide timely feedback on progress or issues, so potential risks can be addressed early.

Conclusion of Top 10 Brass CNC Machining Suppliers

Selecting the right CNC machining supplier is crucial for any manufacturing project. By understanding the strengths and limitations of each supplier and considering your specific needs (such as lead time, machining precision, batch size), companies can make more informed decisions. In today’s globalized world, whether for local manufacturing or international procurement, businesses should flexibly choose the right supplier to ensure production efficiency and product quality. Establishing clear communication and quality control systems during collaboration will effectively avoid unnecessary risks and costs. We hope this article helps you in selecting the best brass CNC machining supplier, and assists you in finding the most suitable partner for high-quality product manufacturing.