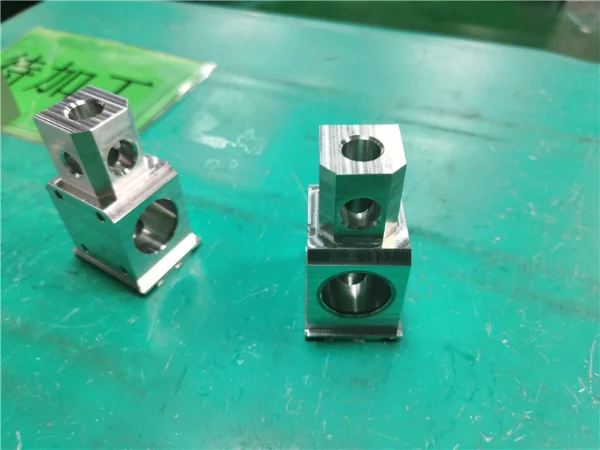

Wire EDM (Electrical Discharge Cutting) achieves non-contact machining through pulsed discharge between a molybdenum wire electrode and the workpiece, splitting the conductive workpiece in half while significantly reducing stress and deformation during the splitting process and removing excess material. The following is about wire EDM service introduction.

Key Advantages of wire edm service:

Precision Control: Laser positioning accuracy reaches ±0.002mm, and surface roughness Ra ≤ 0.4μm, meeting the stringent requirements of aerospace parts.

Material Compatibility: It can process conductive materials with hardnesses above HRC60, such as titanium alloy (TC4) and high-temperature alloys (Inconel 718), as well as other difficult-to-cut materials.

Stress-Free Machining: Non-contact discharge minimizes material deformation, and the heat-affected zone is kept to within 5μm, making it particularly suitable for machining thin-walled parts

The main categories of wire EDM service

In the field of precision machining, EDM (electrical discharge cutting) primarily encompasses medium-wire and slow-wire cutting, representing different high-precision cutting methods. To optimize machining processes, it’s important to understand the differences in speed, precision, and other aspects of medium-wire, slow-wire, and the overall concept of EDM.

Comparison of core technical parameters

| Technical Indicator | Medium wire EDM service | Slow wire EDM service |

|---|---|---|

| Wire Travel Method | Reciprocating wire travel (1~12 m/s) | Unidirectional wire travel (0.001~0.25 m/s) |

| Electrode Wire Characteristics | Molybdenum wire (diameter 0.18~0.25mm, reusable 3~5 times) | Brass/coated zinc wire (diameter 0.02~0.3mm, disposable) |

| Working Fluid | Emulsion (concentration 5%~8%) | Deionized water (conductivity 15~30 μS/cm) |

| Machining Accuracy | ±0.005~0.01 mm | ±0.001~0.005 mm |

| Surface Roughness | Ra 0.8~3.2 μm | Ra 0.1~0.8 μm |

| Equipment Cost | 50~150 million yuan | 300~800 million yuan |

Comparison of processing performance and efficiency

Material adaptability

| Material Type | Medium-Speed Wire EDM Parameters | Slow-Speed Wire EDM Parameters |

|---|---|---|

| Mold Steel Cr12 (50mm thick) | Rough cutting efficiency 120 mm²/min, 3 cuts to achieve Ra0.8 μm | Rough cutting efficiency 60~80 mm²/min, 5 cuts to achieve Ra0.4 μm |

| Titanium Alloy TC4 (30mm thick) | Peak current 4~6 A, kerosene-based working fluid | Peak current 3~5 A, IPG-DPS pulse power technology |

| Hard Alloy WC (15mm thick) | Not applicable (prone to wire breakage) | 5 finishing passes, surface roughness Ra0.8 μm |

Precision control capability

Medium Wire EDM:

Precision is achieved through multiple cuts (rough cut + two finishing passes), with a heat-affected zone of approximately 10-15 μm. Compensation parameters are manually adjusted, resulting in a CPK value of 1.33-1.67 for batch processing.

Slow Wire EDM:

Closed-loop control using a linear encoder achieves a full-stroke positioning accuracy of ±2 μm. AI-powered adaptive control systems (such as GF Machining Solutions’ Variocut) optimize discharge parameters in real time.

Service process and quality control

Drawing Analysis: Import DXF/DWG files, and AI automatically optimizes cutting paths (e.g., machining irregular holes in medical components).

Process Parameter Matching: Select electrode wire diameter (0.1-0.3mm) and discharge parameters based on material thickness (0.1-300mm).

Process Execution: Utilizes dual-drive linear motors to achieve 45° taper cutting (e.g., machining mold cavity slopes).

Quality Inspection and Delivery: Full-dimensional inspection using a 3D measuring instrument, with ISO 9001 quality reports.

Typical application of wire edm service

Medium Wire EDM Applications

Automotive Molds: Transmission Gear Cavity (Material: 20CrMnTi, Accuracy: ±0.01mm, Surface Ra: 1.6 μm)

Hardware: Motor Silicon Steel Sheet (Thickness: 0.3mm, Lamination Factor: ≥98.5%)

Mass Production: Air Conditioning Compressor Blades (Daily Production: 3,000 pieces, Qualified Product Rate: 99.2%)

Slow Wire EDM Applications

Aerospace: Turbine Blade Film Holes (TC4 Titanium Alloy, Hole Diameter Tolerance: ±0.003mm)

Medical Implants: Acetabulum Prosthesis (Ti-6Al-4V, Surface Ra: 0.4 μm, Burr-free)

Precision Molds: Semiconductor Packaging Molds (Material: Tungsten Carbide, Cutting Accuracy: ±0.001mm)

Comparison of operating costs and efficiency analysis

| Technical Indicator | Medium wire EDM service | Slow wire EDM service |

|---|---|---|

| Wire Travel Method | Reciprocating wire travel (1~12 m/s) | Unidirectional wire travel (0.001~0.25 m/s) |

| Electrode Wire Characteristics | Molybdenum wire (diameter 0.18~0.25mm, reusable 3~5 times) | Brass/coated zinc wire (diameter 0.02~0.3mm, disposable) |

| Working Fluid | Emulsion (concentration 5%~8%) | Deionized water (conductivity 15~30 μS/cm) |

| Machining Accuracy | ±0.005~0.01 mm | ±0.001~0.005 mm |

| Surface Roughness | Ra 0.8~3.2 μm | Ra 0.1~0.8 μm |

| Equipment Cost | 50~150 million yuan | 300~800 million yuan |

Market Trends and Technological Innovation

Intelligent Upgrade: GF Machining Solutions‘ CUT S 400 utilizes an AI-powered adaptive control system, increasing machining efficiency by 30%.

Green Manufacturing: The Sodick AL600P achieves 70% consumables recovery and reduces energy consumption by 26%.

Hybrid Processing: Laser-EDM hybrid technology triples tungsten carbide mold machining efficiency.

Summary of wire edm service introduction

Learn more about our wire EDM services introduction! We offer professional wire EDM (Electro-Discharge Machining) with both medium-speed and slow-speed wires. Leveraging advanced equipment and sophisticated craftsmanship, we can meet diverse machining needs, from routine parts to high-precision, complex molds. Medium-speed wire machining balances efficiency with precision, making it suitable for mass production and applications requiring medium-precision precision. Slow-speed wire machining, renowned for its ultra-high precision and excellent surface quality, is widely used in high-end applications such as aerospace and medical devices.

If you have wire EDM needs, regardless of project size, please feel free to contact us for a detailed quote. We will provide customized solutions and precise quotes tailored to your specific requirements.

FAQ of wire EDM service introduction

How do I choose electrode wire material?

Brass wire (cost-effective, suitable for ordinary steel parts); galvanized molybdenum wire (for high-precision machining, such as aviation parts)

How do I calculate the machining cycle?

For a 100×100mm stainless steel part, for example, fast wire cutting takes 4 hours, while slow wire cutting (Ra 0.4μm) takes 8 hours.

How do I remove the white layer on the surface?

Using the EDM finishing process, the white layer thickness can be controlled to less than 2μm