Choosing a qualified 7050 Aluminum CNC Machining manufacturer is critical for aerospace, defense, and high-load structural applications that demand superior strength, toughness, and fatigue resistance. Compared with standard aluminum alloys, 7050 aluminum is specifically engineered for aircraft-grade performance, making the role of an experienced 7050 Aluminum CNC Machining manufacturer essential for achieving reliable tolerances and consistent material behavior.

This guide explains material properties, machining challenges, applications, surface treatments, and how to evaluate the right supplier.

What Makes 7050 Aluminum Unique for CNC Machining

7050 aluminum is a high-strength aluminum-zinc-magnesium-copper alloy developed for aerospace structures where stress corrosion resistance and mechanical reliability are critical.

Key Material Properties of 7050 Aluminum

- Very high tensile strength

- Excellent resistance to stress corrosion cracking

- Good fracture toughness

- Stable mechanical performance in thick sections

- Superior performance compared with 7075 in structural parts

A professional 7050 Aluminum CNC Machining manufacturer understands how these properties affect toolpath strategy and dimensional control.

CNC Machining Challenges of 7050 Aluminum

Although strong, 7050 aluminum is more demanding to machine than 6061 or 7075.

Machining Behavior

- Higher cutting forces

- Increased tool wear

- Requires rigid fixturing

- Sensitive to heat buildup

An experienced 7050 Aluminum CNC Machining manufacturer uses optimized carbide tooling and controlled cutting parameters to maintain precision.

Recommended Machining Practices

- Medium cutting speeds with stable feeds

- High-quality carbide or coated tools

- Adaptive roughing toolpaths

- High-pressure or mist coolant systems

These practices reduce deformation and ensure part consistency.

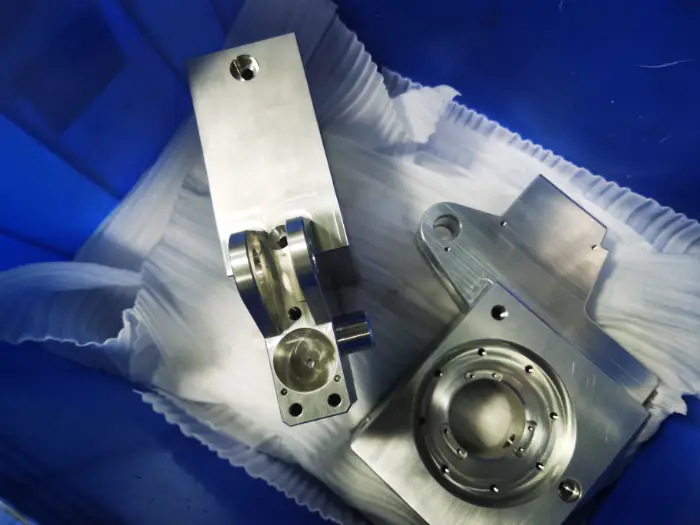

Typical Applications of 7050 Aluminum CNC Parts

Aerospace & Aviation

- Aircraft wing structures

- Fuselage frames

- Landing gear components

- High-stress brackets

Defense & Military

- Structural housings

- Load-bearing support frames

- Precision mounts

Industrial High-Load Equipment

- Heavy-duty machine arms

- Structural plates

- Stress-critical mechanical parts

Because of these requirements, OEMs rely on a proven 7050 Aluminum CNC Machining manufacturer with aerospace-level process control.

Tolerance Capability & Quality Control

Achievable CNC Tolerances

- Standard tolerance: ±0.05 mm

- High-precision tolerance: ±0.01–0.02 mm (geometry dependent)

A qualified 7050 Aluminum CNC Machining manufacturer applies in-process inspection, CMM measurement, and strict material traceability.

Surface Finishing Options for 7050 Aluminum

Common Surface Treatments

- Type II anodizing (corrosion protection)

- Type III hard anodizing (wear resistance)

- Alodine / chromate conversion coating

- Shot peening (fatigue life improvement)

Surface finishing must be carefully controlled to avoid degrading fatigue performance in critical components.

7050 Aluminum vs 7075 in CNC Machining

While often compared, 7050 aluminum offers:

- Better stress corrosion resistance

- More stable performance in thick plate sections

- Slightly improved fracture toughness

However, 7050 generally costs more and requires more advanced machining expertise, reinforcing the value of an experienced 7050 Aluminum CNC Machining manufacturer.

How to Choose the Right 7050 Aluminum CNC Machining Manufacturer

Key Evaluation Factors

- Proven aerospace aluminum machining experience

- Ability to machine large and thick sections

- Advanced CNC equipment (3-axis to 5-axis)

- Material certification and lot traceability

- Controlled environment and inspection capability

Selecting the right 7050 Aluminum CNC Machining manufacturer directly impacts part reliability and lifecycle performance.

Conclusion

7050 aluminum is a premium aerospace-grade material that demands advanced machining expertise. A professional 7050 Aluminum CNC Machining manufacturer ensures tight tolerances, consistent material behavior, and long-term structural integrity for critical applications. By combining optimized tooling, proper fixturing, and aerospace-level quality control, manufacturers can fully unlock the performance benefits of 7050 aluminum CNC parts.you can feel free to contact us Weldo machining for more details and quote.

FAQ of 7050 aluminum cnc machining

Is 7050 aluminum suitable for large CNC-machined structural parts?

Yes. 7050 aluminum performs especially well in thick plates and large cross-section components because it maintains stable mechanical properties and resists stress corrosion cracking under heavy load.

How does 7050 aluminum perform in fatigue-critical CNC applications?

7050 aluminum offers excellent fatigue resistance compared to many other aluminum alloys, making it ideal for high-load and cyclic-stress components such as aircraft structural fittings and load-bearing brackets.

Is 7050 aluminum suitable for complex 5-axis CNC machining?

Yes. 7050 aluminum is well suited for 5-axis CNC machining, especially for aerospace parts with complex geometries, pockets, and angled features. However, it requires precise toolpath planning to avoid chatter and deformation.