Nylon/PA CNC machining

Overview:

Nylon CNC machining is widely used for producing lightweight, wear-resistant, and cost-effective engineering plastic components. As a polyamide (PA) material, nylon offers an excellent balance of mechanical strength, machinability, and price, making it a popular choice for industrial, medical, and automation applications.

Tolerance : up to 0.002 inch

MOQ : prototype welcomed

Price: 10-200 USD/PCs

Delivery time: 1-5 days

Application: For gears, bushings, rollers, insulators, and lightweight structural components where wear resistance, low friction, and cost efficiency are required.

What Is Nylon in CNC Machining?

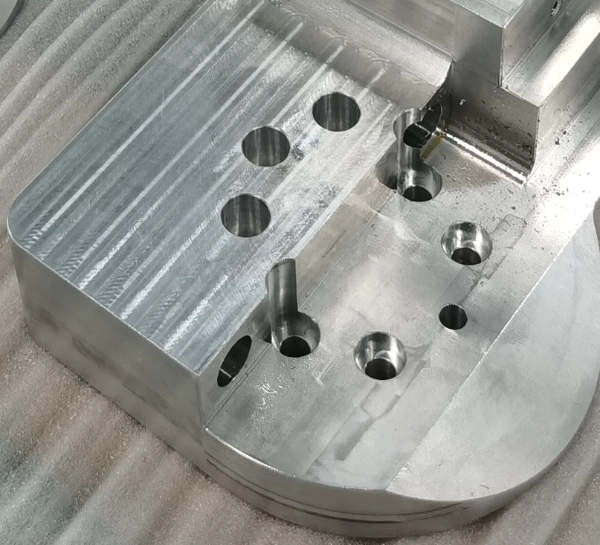

In CNC machining, nylon refers to polyamide (PA) materials commonly processed from solid plastic stock. Nylon machining produces precision components with tight tolerances and smooth surfaces.

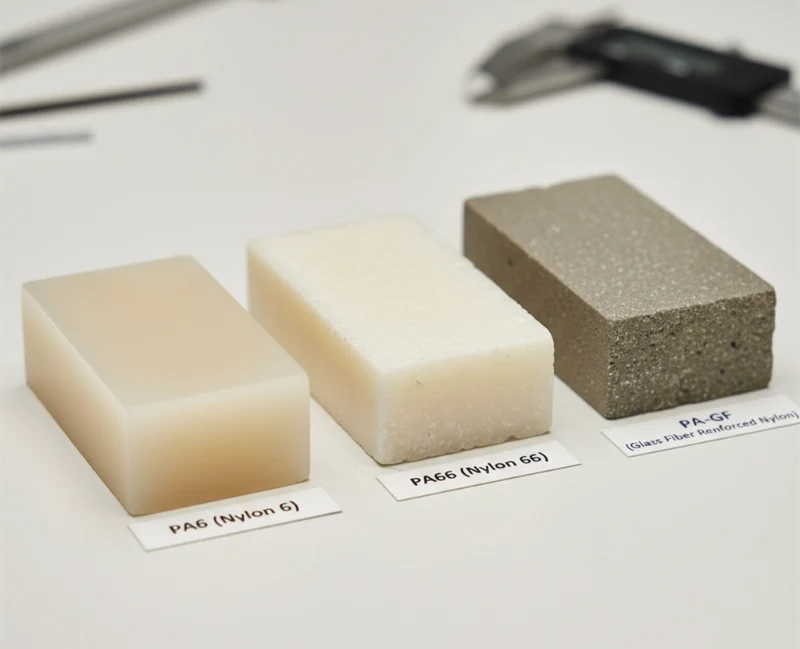

Common nylon grades used in CNC machining:

PA6 (Nylon 6)

PA66 (Nylon 66)

Glass-filled nylon (PA-GF)

Each grade affects machinability, strength, and cost.

Nylon Material Properties for CNC Machining

Understanding material properties is essential for successful nylon machining.

Mechanical Properties of Nylon

Density: ~1.13–1.15 g/cm³

Tensile strength: ~60–90 MPa

Good fatigue resistance

High impact strength

Excellent wear resistance

These properties make nylon CNC machining ideal for moving and load-bearing plastic components.

PA6 vs PA66 in Nylon CNC Machining

PA6 CNC Machining

Better toughness and flexibility

Lower material cost

Slightly higher moisture absorption

PA6 is commonly used for general-purpose nylon machined parts.

PA66 CNC Machining

Higher stiffness and wear resistance

Better dimensional stability

Higher strength at elevated temperatures

PA66 is preferred when tighter tolerances and higher mechanical performance are required.

Design Considerations for Nylon CNC Machining

Design directly impacts the success and cost of nylon CNC machining.

Key design guidelines:

Avoid overly thin walls to prevent deformation

Allow for moisture-related dimensional changes

Use generous internal radii

Specify realistic tolerances

Proper DFM (Design for Manufacturability) review improves part quality and reduces CNC machining cost.

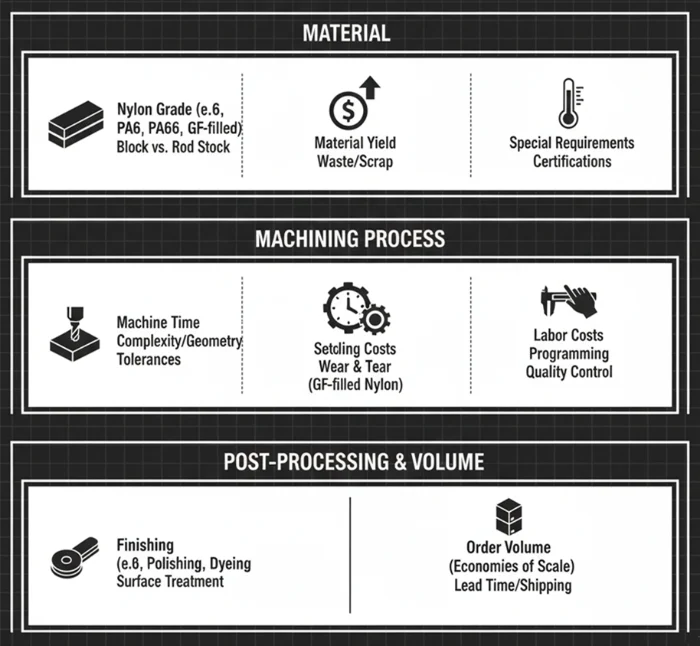

Nylon CNC Machining Cost Factors

The cost of nylon CNC machining depends on several variables.

Primary cost drivers include:

Part size and geometry

Machining time

Tolerance requirements

Order quantity

Compared to metal parts, nylon machining typically offers 30–60% lower total machining cost.

Typical Nylon CNC Machining Cost Range (USD)

For reference purposes only:

Simple nylon CNC machined parts: USD 25–80 / part

Medium complexity nylon parts: USD 40–120 / part

High-precision nylon CNC components: USD 80–180 / part

Larger production volumes significantly reduce unit cost.

Surface Finish Options in Nylon CNC Machining

Surface finish selection affects both performance and appearance in nylon machining part.

Unlike metals, nylon machining usually requires minimal post-processing, helping control cost.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals such as aluminum, magnesium, and titanium.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Electropolish

Removes microscopic protrusions from metal surfaces through electrochemical anodic dissolution, creating a smooth, dense surface free of residual stress and highly corrosion-resistant. Capable of processing complex metals and conductive materials.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, this process enhances hardness, strength, toughness, and wear resistance. It is suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Nylon CNC Machining vs Metal CNC Machining

Nylon CNC is often chosen over metal when:

Weight reduction is critical

Corrosion resistance is required

Electrical insulation is needed

Lower machining cost is desired

In many applications, nylon CNC replaces aluminum or steel without compromising function.

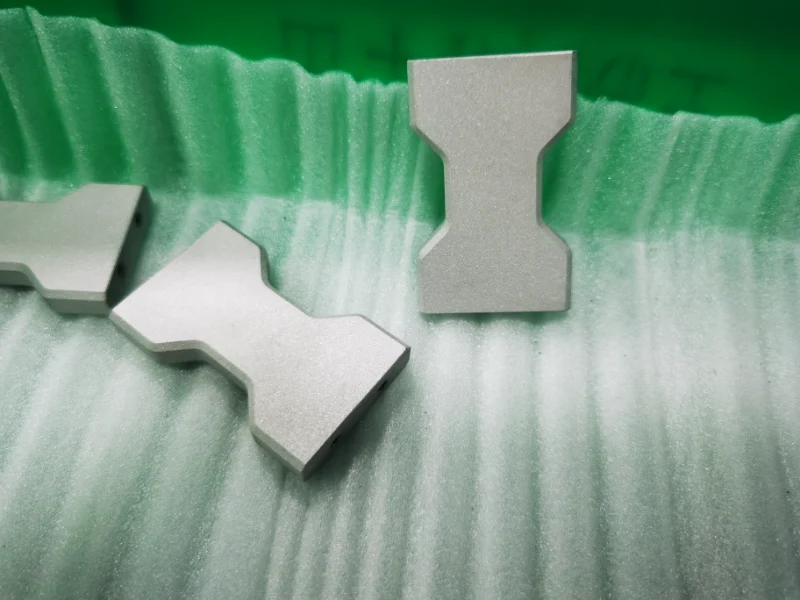

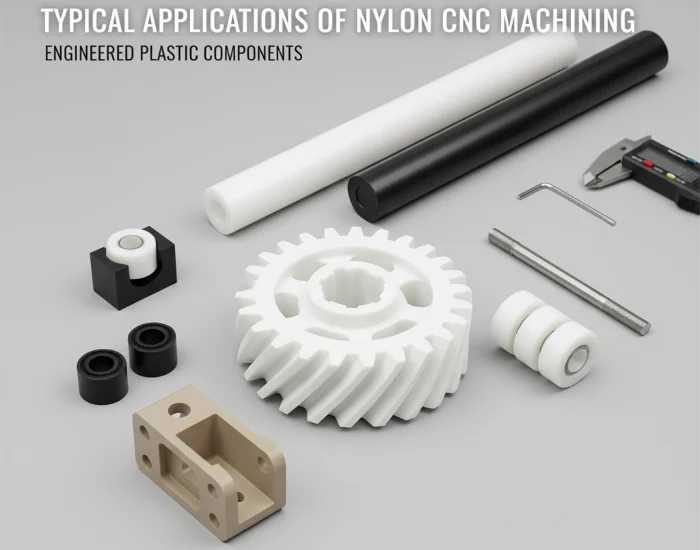

Typical Applications of Nylon CNC Machining

Nylon CNC machining is widely used across industries.

Common applications include:

Gears and bushings

Rollers and wear pads

Spacers and insulators

Mechanical housings

Automation and robotics components

These applications benefit from nylon’s wear resistance and low friction.

Quality Control in Nylon CNC Machining

Precision nylon CNC machining requires proper inspection and process control.

Quality measures include:

Dimensional inspection

Surface finish verification

Material traceability

Moisture control during machining

Professional CNC suppliers ensure consistent quality across batches.

Why Choose Weldo Machining for Nylon CNC Machining

Weldo Machining specializes in nylon machining and other engineering plastic solutions. We help customers select the right nylon grade, optimize designs, and control machining cost.

Our capabilities include:

PA6 and PA66 CNC machining

Tight tolerance plastic machining

Prototype and production support

Competitive pricing and fast lead times

Conclusion: When Nylon CNC Machining Is the Right Choice

Nylon CNC machining offers a cost-effective, lightweight, and durable solution for a wide range of industrial applications. By choosing the correct nylon grade and working with an experienced CNC supplier, manufacturers can achieve reliable performance at a lower cost than metal alternatives. Contact Weldo Machining to discuss your CNC machining project and receive a detailed quotation.