Slow wire EDM machining

Experience unparalleled precision with our Slow Wire EDM Machining—perfect for intricate designs and tight tolerances that demand excellence. Contact us now for a customized quote and elevate your project’s accuracy and quality!

What is slow wire EDM machining

The principle of slow wire EDM machining involves an electrode wire reaching instantaneous temperatures exceeding 6000°C under pulse power supply, causing localized erosion of the workpiece through high heat.

The electrode wire in our Weldo slow wire EDM machines is typically copper or coated wire. According to our technicians, the wire diameter ranges from approximately 0.05 to 0.3 millimeters. The wire feeds at a slow speed of several millimeters per second.This ensures stability during workpiece machining and reduces processing errors.

Material for slow wire EDM machining

Slow wire EDM (Electrical Discharge Machining) is primarily used for machining conductive materials, especially those that are hard, brittle, or difficult to process with conventional cutting tools. Here are the main types of materials suitable for slow wire EDM:

Material :

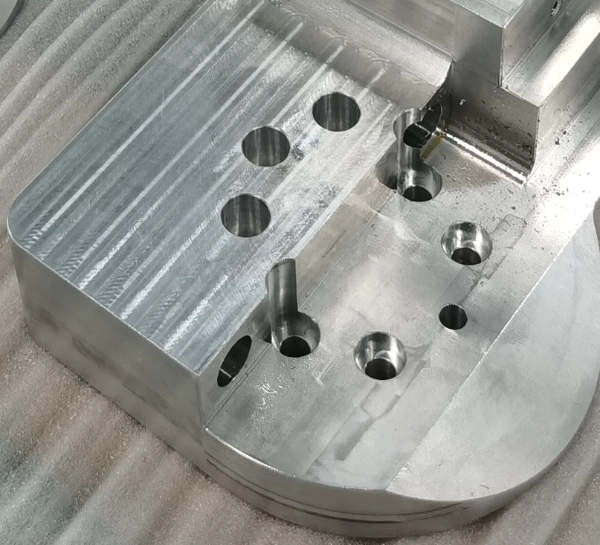

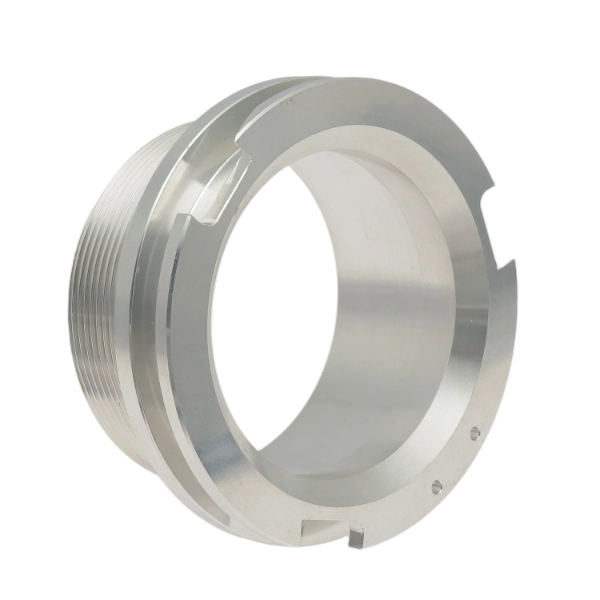

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

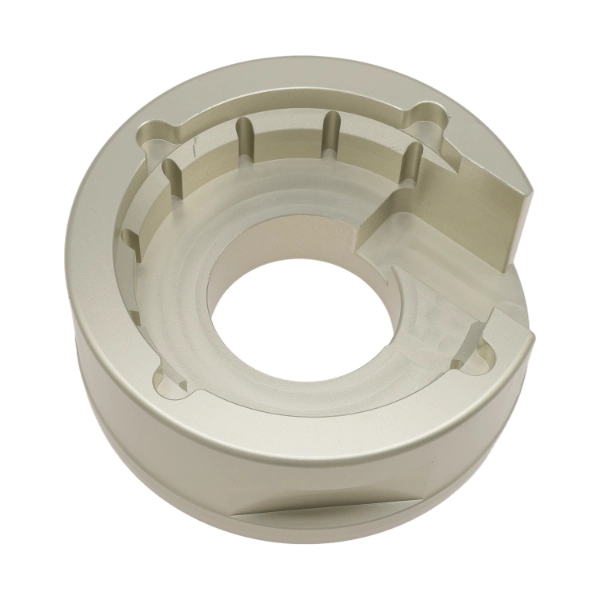

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

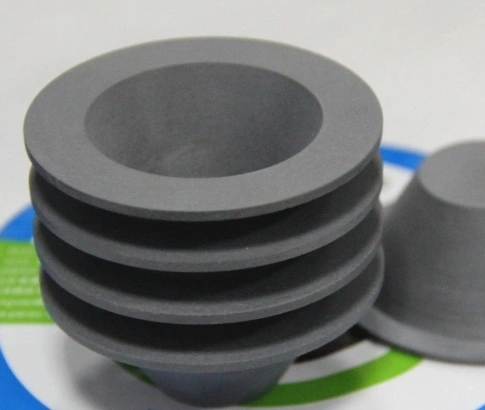

Graphite

Graphite conductivity is used for precision molding to avoid dust pollution caused by machining. It is mainly used for electrode manufacturing and EDM molds.

Color : Black.

Surface finish : Mechanical cutting, pickling, electrolytic treatment, coating, polishing, EDM surface strengthening.

Delivery time : 3-5 days

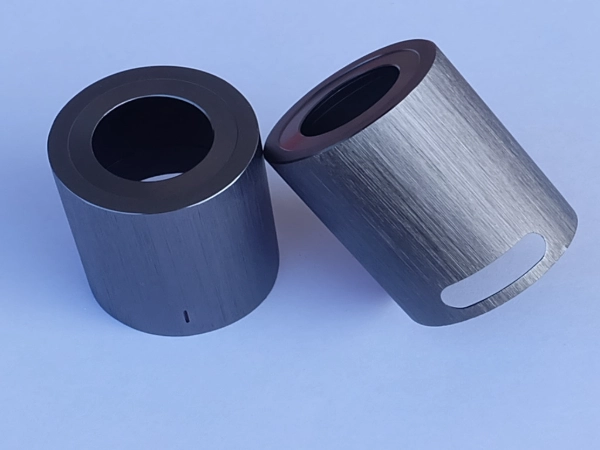

Conductive ceramic part

Conductive ceramics are used in aerospace and other fields due to their high hardness, brittleness, and excellent chemical stability, but they are difficult to process. Using pulsed discharge to generate high temperatures (approximately 10,000°C) to partially melt the ceramic allows for contactless processing, avoiding stress concentration and cracking caused by mechanical processing.

Type : Oxide/non-oxide conductive ceramics, composite conductive ceramics

Color : white, gold, pink black, etc.

Delivery time : 3-5 days

Surface finish for slow wire EDM machining part

For accessories processed by Slow wire EDM machined part, surface treatment options include mechanical, chemical, coating, polishing, and EDM surface strengthening. The specific options and operating points are as follows:

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals such as aluminum, magnesium, and titanium.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Electropolish

Removes microscopic protrusions from metal surfaces through electrochemical anodic dissolution, creating a smooth, dense surface free of residual stress and highly corrosion-resistant. Capable of processing complex metals and conductive materials.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, this process enhances hardness, strength, toughness, and wear resistance. It is suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Slow wire EDM machining capability

| Machining Accuracy | ±0.001~0.005mm |

| Surface Roughness | Ra 0.1~0.8μm |

| Accuracy Control | Constant temperature environment of 20±0.5°C, thermal deformation compensation ≤±1μm |

| First Article Inspection | Three-coordinate measurement CPK≥1.67, key dimension CPK≥2.0 |

| Dual-wire Processing | Rough cut 0.25mm + precision cut 0.1mm automatic switching |

Slow wire EDM machining guide

| Fire Extinguishing Equipment | Two 4kg ABC powder fire extinguishers configured within 30 meters of the processing area |

| Exhaust Gas Treatment | Local exhaust (air volume ≥800m³/h) is enabled during brass wire processing, and the activated carbon filter is replaced every 150 hours |

| Grounding System | TN-S three-phase five-wire system is adopted, grounding resistance ≤4Ω, verified monthly with a resistance tester |

| Overload Protection | Main circuit configured with a 30mA residual-current device, response time <0.1s |

| Electrode Wire Installation | Insulating gloves (voltage resistance 1000V), protective goggles |

| Equipment Maintenance | Anti-smash safety shoes (steel toe impact resistance 200J) |

| Common Fault Elimination | Dust-proof mask (KN95 level), anti-static clothing |

| Machining Accuracy Anomaly | Dimension deviation >0.005mm, use anhydrous ethanol to clean the optical, scale ruler and recalibrate the origin |

| Surface Streaks (Z-axis Direction) | Wire guide wear (radial runout) >0.01mm), replace the wire guide (recommended replacement every 500 hours) |

| Corner Overcutting | Servo gain setting too high, reduce X/Y axis gain to 80%, enable corner deceleration |

| Electrode Wire-related Faults | Frequent wire breakage |

| Frequent Wire Breakage | Check tension fluctuation (allowable range ±0.5N), replace tension sensor (accuracy ±0.1N) |

| Automatic Wire Threading Failure | Clean the wire threading path (compressed air pressure 0.4MPa), check electrode wire diameter consistency (deviation ≤0.002mm) |

Advantage of slow wire EDM machining

Ultra-high precision: Positioning accuracy ±0.001~0.005mm, surface roughness Ra 0.1~0.8μm, no secondary polishing required

Wide material adaptability: Capable of machining difficult-to-cut materials such as cemented carbide (HRC65+) and titanium alloys, heat-affected zone ≤10μm

Superior Stability: Unidirectional wire feed (0.001–0.25 m/s) + single-use electrode wire, processing consistency CPK ≥ 1.67

High Process Integration: Dual-wire auto-switching (coarse wire efficiency 80 mm²/min + fine wire precision 10x improvement)

Application of slow wire EDM machining part

Aerospace: Engine blade molds (titanium alloy TC4, contour error ≤ 0.003 mm)

Medical: Artificial joint molds (cobalt-chromium alloy, surface roughness Ra 0.3μm)

Semiconductor: Chip packaging molds (minimum groove width 0.05mm, perpendicularity error ≤0.001mm/m)

Premium Automotive: Transmission gear molds (7075 aluminum alloy, dimensional stability ≤0.002mm)