When comparing Anodizing vs Alodine, engineers and product designers are choosing between two major aluminum finishing methods used across aerospace, automotive, medical, electronics, and CNC machining industries. Although both are conversion coatings, they provide different levels of protection, serve different functions, and vary in cost, durability, and appearance.

This guide summarizes what CNC engineers, procurement teams, and product developers need to know about Anodizing vs Alodine, including how each process works, suitable materials, key performance differences, and how to select the right finish for your application.

Whether you’re producing aluminum brackets, housings, enclosures, UAV parts, or consumer electronics, understanding these two finishes helps you achieve better corrosion resistance, durability, and overall product quality.

1. What Is Anodizing?

Anodizing is an electrolytic oxidation process used primarily for aluminum and aluminum alloys, though titanium and magnesium can also be anodized. During anodizing, the aluminum part is submerged into an acid electrolyte bath and subjected to an electric current. This artificially thickens the natural oxide layer on the metal surface, creating a hard, wear-resistant ceramic-like coating that is integral to the aluminum itself.

1.1 Key Characteristics of Anodizing

- Produces a hard, dense, corrosion-resistant oxide layer

- The coating is non-conductive (insulating)

- Offers excellent wear resistance and scratch resistance

- Provides aesthetic options such as black, clear, red, blue, gold, green, and more

- Great for parts requiring durability and mechanical stress resistance

- Works exceptionally well with 6061-T6, 6063, 7075, 2024, and 5052 aluminum

- Available in Type I, Type II, and Type III (hard anodizing)

1.2 Suitable Materials for Anodizing

- Aluminum (most common)

- Aluminum alloys (6000, 7000, 5000 series)

- Titanium

- Magnesium

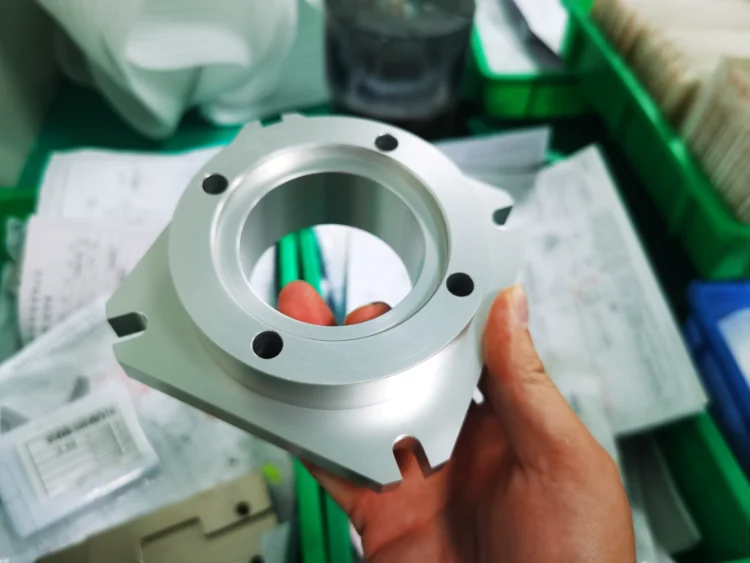

1.3 Anodizing in CNC Machining

In CNC machining, anodizing is typically chosen for:

- Camera and drone housings

- Aerospace components

- Heat sinks and electronic chassis

- Medical instruments

- Consumer electronics shells (like Apple-style finishes)

- High-strength structural parts

Because CNC-machined aluminum parts are often used in demanding environments, anodizing aluminum is one of the most desirable protective finishes.

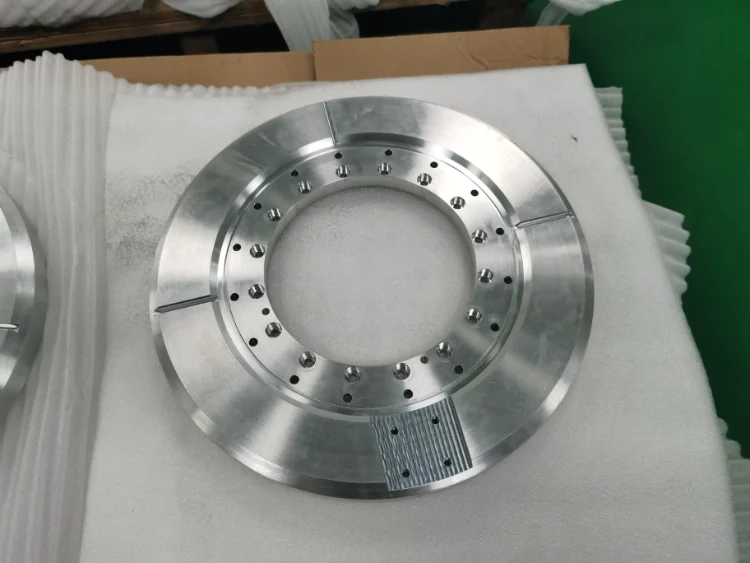

1.4 Types of Anodizing

Type II (Decorative Anodizing)

- Thickness: 5–25 µm

- Good for aesthetics + corrosion resistance

- Best for consumer products

Type III Hard Anodizing (Hardcoat)

- Thickness: 25–100 µm

- Ultra-high durability

- Excellent wear and abrasion resistance

- Common in aerospace, military, robotics, industrial machinery

1.5 Advantages of Anodizing

- Strong corrosion protection

- Hard, scratch-resistant surface

- Colorful cosmetic finishes

- UV and chemical resistance

- Extended part lifespan

1.6 Limitations of Anodizing

- Non-conductive (not suitable for grounding parts)

- More expensive compared to Alodine

- Can cause slight dimensional changes (important for tight tolerances)

2. What Is Alodine? (Chromate Conversion Coating)

Alodine, also known as chromate conversion coating, is a chemical surface treatment primarily applied to aluminum to enhance corrosion resistance while maintaining electrical conductivity. Common trade names include Alodine, Iridite, and Chem Film.

2.1 Key Characteristics of Alodine

- Produces a thin protective chromate film on aluminum

- Available in gold or clear finishes

- Maintains electrical conductivity

- Provides corrosion resistance but not significant wear resistance

- Often used as a paint or powder-coating primer

- Much cheaper than anodizing

- Does not alter dimensional tolerances

2.2 Suitable Materials for Alodine Coating

- Aluminum and aluminum alloys

- Magnesium (in certain formulations)

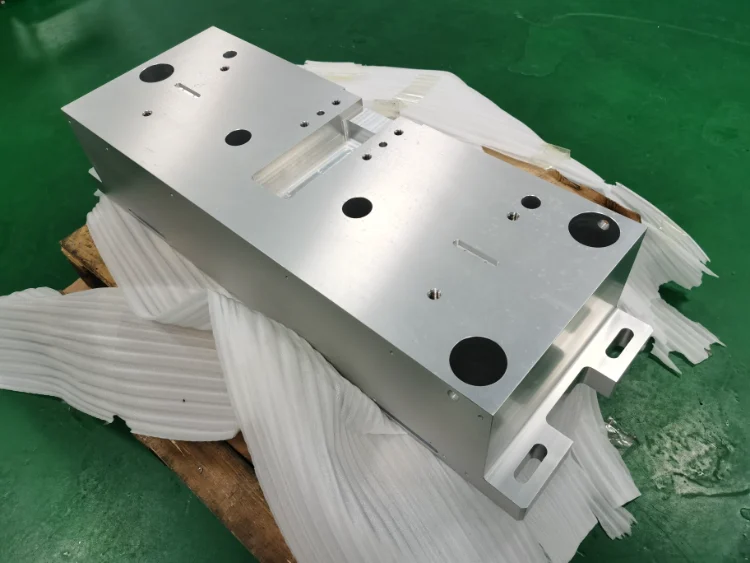

2.3 Alodine in CNC Machining

Alodine coating is extremely common in aerospace CNC components requiring:

- Low electrical impedance

- Lightweight corrosion protection

- Surface prep before painting

- Minimal dimensional impact

Also widely used for:

- Chassis and grounding components

- Enclosures requiring conduction

- EMI shielding components

2.4 Types of Alodine

Alodine 1200 (Gold Chromate)

- High corrosion resistance

- Conductive

- Golden surface

Alodine 1000 (Clear Chromate)

- Clear appearance

- Suitable for cosmetic projects requiring a natural metal look

2.5 Advantages of Alodine

- Inexpensive

- Fast processing

- Conductive surface

- No dimensional change

- Ideal primer for paint

2.6 Limitations of Alodine

- Lower wear resistance

- Not as durable as anodizing

- Limited color choices

3. Anodizing vs Alodine: Side-by-Side Comparison

To meet your request for the keyword Anodizing vs Alodine (density 3%), below is a detailed comparison table.

| Feature | Anodizing | Alodine |

|---|---|---|

| Process | Electrolytic oxidation | Chemical conversion |

| Durability | High (ceramic-like) | Moderate |

| Conductivity | Non-conductive | Conductive |

| Corrosion Resistance | Excellent | Good |

| Color Options | Many (black, red, blue, etc.) | Gold or clear |

| Thickness | 5–100 µm | <1 µm |

| Wear Resistance | Strong | Minimal |

| CNC Machining Use | High-strength parts | Grounding parts, chassis |

| Cost | Higher | Low-cost |

| Dimensional Change | Yes (small) | None |

4. Cost Comparison: Anodizing vs Alodine

4.1 Anodizing Cost

Common cost ranges:

- Type II anodizing: $60–$200 per batch, or $2–$10 per part

- Type III hard anodizing: $80–$300 per batch, or $5–$20 per part

Factors affecting anodizing cost:

- Part size

- Thickness requirement

- Color

- Alloy type (7075 costs more than 6061)

- Surface area

- Tolerance adjustment

4.2 Alodine Cost

- Much cheaper than anodizing

- Typical cost: $1–$3 per part, or $20–$80 per batch

Why cheaper?

- Faster process

- No coloring

- No electrical current needed

4.3 Which Is Cheaper?

Alodine is significantly cheaper.

If a CNC project has a large volume or does not require wear resistance, Alodine is the more cost-effective choice.

5. How to Choose Between Anodizing vs Alodine

Choose Anodizing if:

- You need strong wear resistance

- You want colored finishes

- You need long-term durability

- The part will face abrasion, heat, or harsh environments

- You are producing consumer-grade aluminum products

Choose Alodine if:

- You need electrical conductivity

- You want to keep dimensional accuracy

- You need a fast, low-cost finish

- The part requires painting or powder coating

- Aerospace regulations require chromate conversion coating

This selection method ensures proper function, extended part lifecycle, and cost efficiency.

6. Applications of Anodizing vs Alodine in CNC Machining

Industries using anodizing:

- Aerospace

- Robotics

- Consumer electronics

- Industrial tooling

- Medical device parts

- Automotive aftermarket components

Industries using Alodine:

- Aerospace (FAA-approved finishes)

- Defense systems

- Electrical housings

- Heat dissipation components requiring grounding

- Automotive body components

7. Final Recommendation for CNC Machined Aluminum

If your aluminum CNC parts need:

- Decorative finish → Choose Anodizing

- Structural reliability → Type III Hard Anodizing

- Conductivity → Choose Alodine

- Low cost → Alodine coating

- Corrosion prevention + painting prep → Alodine

- Luxury appearance → Anodizing

- High hardness → Hardcoat anodizing

For many projects, customers actually use both:

- Alodine for internal chassis

- Anodizing for external surfaces

8. Why Choose Weldo Machining for Surface Finishing?

At Weldo Machining, we provide:

- High-precision aluminum CNC machining

- Full finishing options including Anodizing, Hard Anodizing, Alodine, Electropolish, Powder coating, Bead blasting, and more

- Tight tolerances up to ±0.01 mm

- Professional quality control and material certifications

- Fast lead times and competitive U.S.-oriented pricing

If you’re unsure which surface treatment is best, our engineering team can analyze your application and provide the perfect recommendation.

Contact Weldo Machining today for expert guidance, accurate quotations, and premium aluminum finishing solutions for your next CNC project.