Choosing a reliable cnc 316L inner housing manufacturer is critical for industries that demand corrosion resistance, dimensional accuracy, and long-term reliability. Inner housings often serve as core structural or functional components, operating in enclosed, pressurized, or corrosive environments. This page explains why 316L stainless steel is widely used for inner housings, how CNC machining ensures precision, and what to consider when selecting a cnc 316L inner housing manufacturer.

Why 316L Is Ideal for CNC Inner Housings

316L stainless steel is a low-carbon austenitic stainless steel known for its excellent corrosion resistance and mechanical stability. For inner housing components, material performance directly impacts product safety and service life.

Key advantages of 316L include:

- Superior corrosion resistance

- Excellent performance in humid and chemical environments

- Good weldability and formability

- Stable mechanical properties

A professional cnc 316L inner housing manufacturer understands how to machine 316L efficiently while maintaining tight tolerances.

What Is a CNC 316L Inner Housing?

A CNC 316L inner housing is a precision-machined internal enclosure or structural shell made from 316L stainless steel. These components often protect sensitive internal parts or provide structural alignment within an assembly.

Common functions include:

- Structural support

- Fluid or gas containment

- Internal alignment and positioning

- Protection of sensitive components

A qualified cnc 316L inner housing manufacturer ensures consistent quality across all production stages.

CNC Machining Capabilities for 316L Inner Housings

CNC machining is the preferred manufacturing method for complex inner housings made from 316L stainless steel.

Typical processes include:

- CNC milling for complex geometries

- CNC turning for cylindrical housings

- Multi-axis machining for internal features

- Precision boring and threading

An experienced cnc 316L inner housing manufacturer uses optimized cutting parameters to manage work hardening and tool wear.

Mechanical Properties of 316L Stainless Steel for Inner Housings

Understanding material properties is essential when selecting a cnc 316L inner housing manufacturer.

Key mechanical properties of 316L:

- Tensile strength: ~485 MPa

- Yield strength: ~170 MPa

- Excellent toughness at low temperatures

- High resistance to pitting and crevice corrosion

These properties make 316L ideal for demanding inner housing applications.

Design Considerations for CNC 316L Inner Housings

Design quality directly affects machining efficiency and part cost.

Important design factors include:

- Wall thickness uniformity

- Internal corner radii

- Tolerance specification

- Surface roughness requirements

A professional cnc 316L inner housing manufacturer provides DFM feedback to optimize both performance and cost.

Surface Finishing Options for CNC 316L Inner Housings

Surface finishing plays a critical role in both performance and compliance.

Common surface finishes include:

- As-machined finish

- Passivation for enhanced corrosion resistance

- Polishing for smooth internal surfaces

- Electropolishing for medical and hygienic applications

A reliable cnc 316L inner housing manufacturer selects finishes based on functional requirements rather than appearance alone.

CNC 316L Inner Housing Applications

316L inner housings are used across multiple high-value industries.

Typical applications include:

- Medical devices and surgical equipment

- Pharmaceutical processing systems

- Food and beverage machinery

- Semiconductor equipment

- Chemical and fluid handling systems

In these sectors, choosing the right cnc 316L inner housing manufacturer is essential for compliance and reliability.

CNC 316L Inner Housing Cost Factors

The cost of CNC-machined 316L inner housings depends on several factors.

Key cost drivers:

- Part complexity and internal features

- Tolerance and surface finish requirements

- Machining time and tool wear

- Production volume

An experienced cnc 316L inner housing manufacturer helps balance cost and performance through smart engineering decisions.

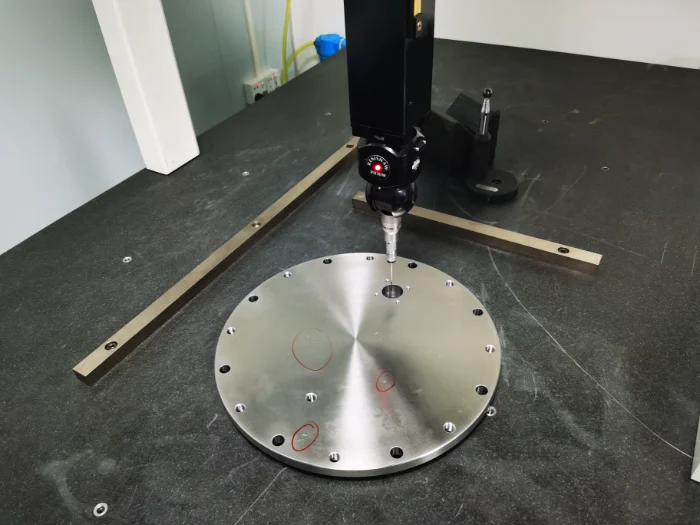

Quality Control in CNC 316L Inner Housing Manufacturing

Quality assurance is critical for inner housing components.

Typical inspection methods include:

- Dimensional inspection with CMM

- Surface roughness measurement

- Material certification and traceability

- Visual and functional inspection

A trusted cnc 316L inner housing manufacturer follows strict quality control procedures.

Prototype and Production Support

A capable cnc 316L inner housing manufacturer supports both prototyping and production.

Benefits include:

- Fast turnaround for prototypes

- Stable quality for repeat production

- Scalable manufacturing capacity

- Engineering support throughout the project lifecycle

This flexibility reduces development risk and accelerates time to market.

Why Choose Weldo Machining as Your CNC 316L Inner Housing Manufacturer

Weldo Machining is an experienced cnc 316L inner housing manufacturer specializing in precision stainless steel components for demanding applications.

Our advantages include:

- Expertise in 316L CNC machining

- Advanced multi-axis CNC equipment

- Strict quality control standards

- Competitive pricing and responsive support

We work closely with customers to deliver reliable, high-precision inner housing solutions.

Conclusion: Selecting the Right CNC 316L Inner Housing Manufacturer

Choosing the right cnc 316L inner housing manufacturer ensures product reliability, corrosion resistance, and long-term performance. With the right material expertise, machining capability, and quality control, CNC-machined 316L inner housings meet the highest industry standards. Contact Weldo Machining to discuss your application requirements and receive a detailed quotation.