As the demand for conductivity, thermal management, and structural complexity increases in advanced manufacturing sectors, copper components are becoming more vital across industries like new energy vehicles, 5G communications, and medical equipment. CNC machining has become the mainstream solution for copper part production, thanks to its precision and stability. Choosing a CNC copper machining manufacturer with systematic capabilities is now a key factor in ensuring product performance and delivery efficiency.

Complete CNC Copper Machining Process: From Design to High-Precision Delivery

CNC copper machining is not just about cutting; it involves an integrated process of material selection, design review, machining, surface treatment, and inspection. Understanding this process helps ensure quality and lead time control.

Engineering Review & DFM

The manufacturer evaluates part drawings for geometry, tolerance feasibility, and machining constraints. A proper Design for Manufacturability (DFM) review helps prevent costly revisions and low yield in production.

Copper Material Selection & Traceability

Choosing the right copper grade (e.g., C1100, H62, C17200) is crucial. Manufacturers provide material certification (RoHS, SGS) and maintain lot traceability to ensure consistent quality.

CAM Programming & Process Design

Using CAM software, machining paths, clamping strategies, and cutting sequences are optimized for accuracy, thermal management, and tool life. Simulations are often used to avoid collisions and undercuts.

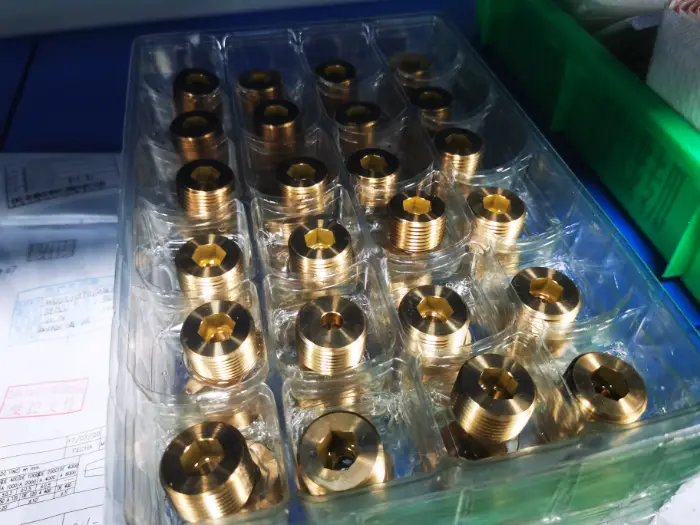

CNC Machining Execution

High-precision turning, milling, drilling, tapping, and 5-axis machining are applied. Heat management and tool wear are closely monitored to prevent deformation and burrs.

Surface Treatment & Secondary Finishing

Copper surfaces require plating or passivation to prevent oxidation. Key surfaces may need post-processing to restore tight tolerances after coating.

Inspection & Delivery

CMM, optical, and visual inspections are conducted. Final reports include dimensional data, material certifications, and batch tracking for full quality traceability.

Core Competencies of CNC Copper Machining Manufacturers

Different manufacturers vary not only in equipment but also in process experience, quality consistency, engineering support, and system maturity. These capabilities define whether a supplier is truly worth long-term cooperation.

- Deep understanding of copper’s machining behavior: softness, thermal expansion, and burr formation

- Advanced equipment: 5-axis machines, tool wear monitoring, climate-controlled workshops

- Engineering collaboration: support for design improvement, tolerance analysis, cost reduction

- Robust processes: ISO-certified, automated QC, and consistent performance across batches

How to Choose the Right Copper Material for CNC Machining?

Copper materials vary in conductivity, strength, machinability, and cost. Scientific material selection is crucial to achieving both function and efficiency.

| Material | Advantages | Limitations | Applications |

|---|---|---|---|

| C1100 (T2) | Excellent conductivity & ductility | Low strength, oxidizes easily | Busbars, electrodes, heat sinks |

| H62 Brass | Easy to machine, moderate strength | Lower conductivity, tarnishes | Pins, housings, fittings |

| C14500 | Excellent machinability | Weaker weldability | Terminals, precision turned parts |

| C17200 (BeCu) | High strength, fatigue resistance | High cost, dust safety precautions | Springs, aerospace connectors |

| C5191 (Phosphor Bronze) | Corrosion/abrasion resistance, springy | Hard to cut, tool wear | Contact parts, durable clips |

Precision Control in CNC Copper Parts: How to Meet International Tolerance Standards?

Tolerance control ensures fit, electrical performance, and batch consistency. Understanding ISO 2768, ISO 286, and IT grades helps you set functional tolerances and manage cost.

International Standards

- ISO 2768: General tolerances for linear and angular dimensions

- ISO 286: Defines IT grades for holes and shafts

- DIN 7168: German standard equivalent to ISO 2768

Machining Capabilities

| Process | Achievable Tolerance | IT Grade |

|---|---|---|

| CNC Turning | ±0.005 ~ ±0.01 mm | IT6–7 |

| CNC Milling | ±0.01 ~ ±0.02 mm | IT7–8 |

| Boring/Grinding | ±0.003 ~ ±0.005 mm | IT6 |

| 5-Axis Milling | ±0.003 mm | IT6 |

Best Practices

- One-time fixturing for critical dimensions: Minimizes misalignment during refixturing.

- 5-axis machining: Reduces work position errors by machining multiple faces in one setup.

- SPC + FAI + CMM: Statistical control, first article inspection, and coordinate measuring together ensure precision.

- Finish toolpaths & thermal compensation: Counteract temperature shifts and refine final dimensions.

How to Prevent Oxidation in Copper Parts? Common Surface Treatment Methods

Copper oxidizes rapidly. Suitable surface treatment not only prevents corrosion but improves solderability, appearance, and long-term reliability.

| Method | Function | Use Cases |

|---|---|---|

| Nickel Plating | Corrosion resistance, solderability | Electrical contacts |

| Silver/Tin Plating | Conductivity, solderability | Signal connectors, terminals |

| Polishing | Aesthetics, smooth assembly | Decorative or visible parts |

| Passivation | Anti-tarnish, mild protection | Internal parts, low-cost items |

Common Drawing Mistakes and Design Optimization for Manufacturability

Avoiding common design errors significantly improves yield and reduces trial costs.

| Design Mistake | Risk | Recommendation |

|---|---|---|

| Overly tight tolerances | Cost and machining difficulty | Limit critical tolerances to function zones |

| Sharp internal corners | Tool access, stress concentration | Use corner radii (e.g., R0.3–0.5 mm) |

| Deep/thin wall sections | Vibration, deformation | Increase wall thickness or redesign |

| No surface finish callout | Surface inconsistency | Specify Ra levels on key surfaces |

Quality Management System in CNC Copper Machining (ISO / IATF)

A robust quality system underpins stable production and high-end industry compliance. Leading CNC copper manufacturers adopt the following controls:

IQC: Incoming Quality Control

Verifies material certifications, physical condition, and chemical properties of raw copper or outsourced components. Prevents non-conforming inputs from entering production.

IPQC: In-Process Quality Control

Regular inspections during machining monitor tool wear, dimensional consistency, and surface finish. Early detection ensures continuous process stability.

OQC: Outgoing Quality Control

Final inspection of dimensional accuracy, coating integrity, and packaging quality. Accompanied by certificates and test reports before shipment.

FAI: First Article Inspection

Comprehensive inspection of initial part in a production run. Confirms setup, toolpaths, and machine programs meet specification. Reduces mass-production error risk.

Control Plan + Process Flowchart + PPAP

Defines how and where to inspect, at what frequency, and by whom. Flowcharts show process sequencing. PPAP documentation supports automotive/medical compliance, validating long-term stability and capability.

How to Choose a Reliable CNC Copper Machining Supplier?

Beyond price and appearance, a supplier’s real value lies in engineering insight, response speed, and process stability.

| Factor | Evaluation Tip |

|---|---|

| Equipment capability | 5-axis machining, CMM, automation availability |

| Copper expertise | Experience with multiple grades, burr control, plating |

| Engineering service | Provides DFM, tolerance tuning, cost reduction advice |

| Certifications | ISO 9001, IATF 16949, medical ISO 13485 as needed |

| Flexibility & delivery | Supports prototypes, small batch, rapid delivery |

Surface Roughness Standards for CNC Copper Parts

Surface finish (Ra) affects electrical flow, mating tolerance, and visual appeal. ISO 4287 & 1302 define Ra requirements by function.

| Roughness Grade | Ra (μm) | Appearance | Application |

|---|---|---|---|

| N1 | 0.025 | Mirror polish | Optical, RF-critical areas |

| N3 | 0.1 | Ultra-smooth | Electrical paths, sensors |

| N5–N6 | 0.4–0.8 | Standard CNC cut | Connectors, mechanical housing |

| N8 | 1.6–3.2 | Functional finish | Internal structural parts |

Machining method reference:

| Method | Typical Ra (μm) |

|---|---|

| Polishing | 0.025–0.1 |

| Grinding | 0.1–0.4 |

| CNC Milling | 0.4–1.6 |

| Sandblasting | ≥3.2 |

Conclusion

CNC copper machining is not just about equipment; it’s a combination of engineering precision, material knowledge, process control, and a robust inspection and management system. Choosing the right machining service provider ensures that your parts are fully functional, reliable, and can seamlessly transition from prototyping to mass production. In today’s highly competitive market, your CNC machining service provider should be an integral part of your product development team.