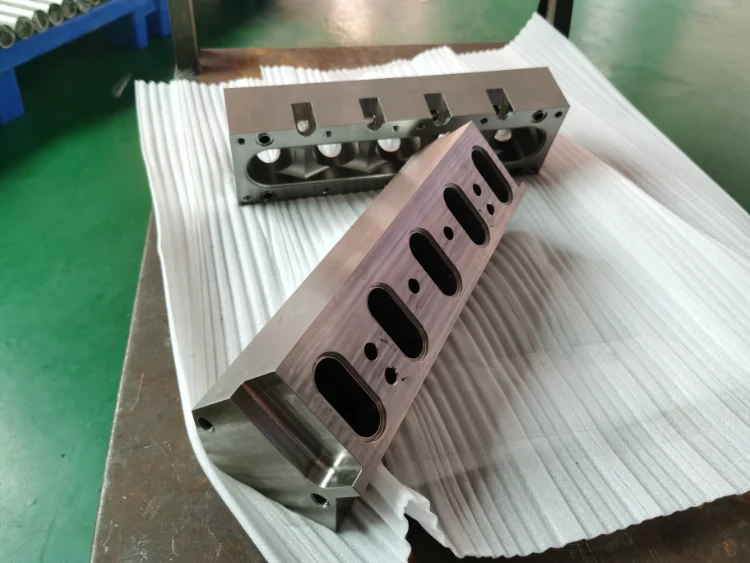

In high-end cnc engine block machining, the cylinder block, as a core component, directly impacts performance and lifespan due to its material and machining precision. Recently, our company received a stainless steel engine cylinder block machining project. Through a composite process of “3-axis roughing + 5-axis finishing + EDM,” we achieved a critical dimensional accuracy of ±0.01mm, greatly assisting the client’s automotive powertrain modification and upgrade.

Material Breakthrough: Performance Advantages and Challenges of Stainless Steel Cylinder Blocks

Material Advantages

Based on the client’s requirements, this cylinder block uses 347 high-strength stainless steel, possessing three core advantages:

Corrosion Resistance: The surface oxide film’s corrosion resistance is 5 times that of cast iron, adapting to humid and high-temperature environments;

High-Temperature Stability: Long-term operating temperature up to 816℃, short-term withstand temperature up to 900℃, melting point 1398℃ to 1446℃, and thermal deformation reduced by 70% compared to aluminum alloys;

Structural Strength: Tensile strength 520-550 MPa, meeting the requirements of high loads and high speeds.

Machining Challenges and Solutions

The high hardness (HRC28-35), low thermal conductivity, and work-hardening properties of stainless steel present challenges:

Tool Wear: Using TiAlN coated end mills at cutting speeds of 80-120 m/min extends tool life by 3 times;

Cutting Force Control: A strategy of “small depth of cut (0.2 mm), high feed rate (0.15 mm/r)” reduces spindle load by 40%;

Thermal Deformation Suppression: Spraying 5-10℃ low-temperature cutting fluid during machining ensures dimensional stability.

Precision Machining Process Synergy

3-Axis Machining Center: Efficient Roughing

The roughing stage utilizes a high-rigidity 3-axis vertical machining center:

Layered Milling: Single-layer depth of cut 2 mm, total allowance controlled within 1.5 mm;

Dynamic Feed Adjustment: Feed rate adjusted in real-time according to material hardness (80-120 mm/min);

Chip Removal Optimization: Spiral chip chute combined with high-pressure air gun purging avoids secondary cutting.

Upon completion of this stage, the uniformity of allowance in key cylinder block components reaches ±0.05mm, laying the foundation for precision machining.

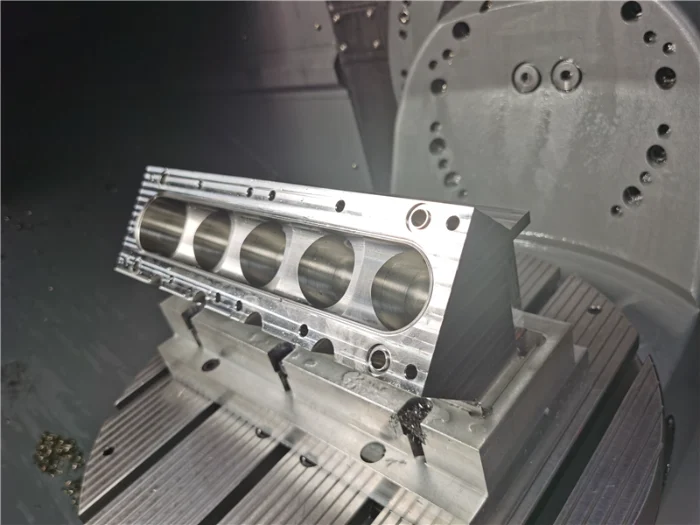

5-Axis Machining: Surface Carving

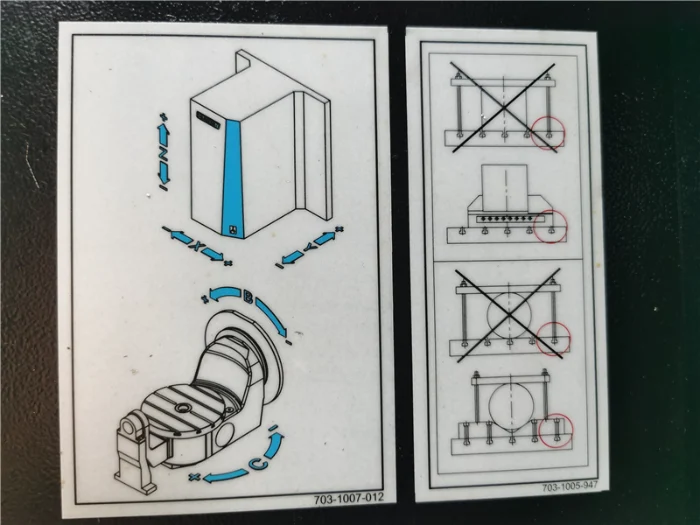

The precision machining stage utilizes a 5 axis machining center (such as Haas and Hurco 5 axis cnc machining center):

Cylinder bore precision boring: Diamond-coated boring tools are used with a feed rate of 0.05mm/r to achieve a cylindricity ≤0.005mm;

Water jacket machining: 5-axis linkage control of the tool angle achieves a surface roughness of Ra0.8μm for the flow channel, increasing heat dissipation efficiency by 20%;

Crankshaft bore coaxiality: Using the two locating pin holes on the bottom surface as a reference, 5-stage hole machining is completed in a single setup, with an error ≤0.008mm.

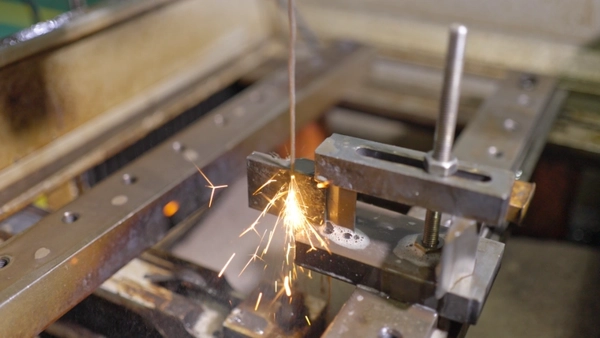

EDM wire machining: Micron-Level Finishing

For machining imperfections on cylinder blocks (such as intersection lines of holes and narrow slots), a medium wire EDM machine is introduced:

Precision Compensation: The online measurement system provides real-time data feedback and automatically adjusts the discharge energy (voltage 20-100V, current 2-10A), stabilizing the kerf width at 0.1±0.01mm;

Surface Quality: Multiple cutting processes (roughing → semi-finishing → finishing) reduce the surface roughness from Ra6.3μm to Ra1.6μm, preventing micro-cracks;

Efficiency Optimization: Intelligent pulse power supply control increases the cutting speed to 120mm²/min, improving efficiency by 40%.

CNC Engine Block Machining Material Option

Aluminum Alloy : Common materials include aluminum-silicon alloys. Lightweight, they effectively reduce the overall weight of the engine, improving fuel economy. They also have good thermal conductivity, aiding in engine cooling.

Stainless Steel : Excellent corrosion resistance, protecting the engine block from corrosion in harsh environments. High strength ensures stability under high pressure. However, stainless steel is more expensive and relatively difficult to machine.

Car Engine Block Machining Surface finish:

Phosphating : Forms a phosphate chemical conversion film on the cylinder block surface. This film improves corrosion resistance, preventing rust during storage and use. It also enhances the adhesion between the cylinder block and subsequent coatings, providing a good foundation for subsequent painting and other surface treatment processes.

Anodizing (for Aluminum Alloy Cylinder Blocks) : Forms a dense oxide film on the aluminum alloy cylinder block surface, significantly improving surface hardness, wear resistance, and corrosion resistance. This oxide film can also be dyed to give the cylinder block different colors to meet certain aesthetic requirements.

Coating : For example, spraying a high-temperature resistant coating can improve the cylinder block’s resistance to oxidation and thermal shock in high-temperature environments, protecting the internal structure. Spraying an anti-friction coating can reduce friction between moving parts such as the piston and the cylinder block, reducing energy loss and improving engine efficiency.

Electroplating : For example, chrome plating can give the cylinder block surface extremely high hardness and wear resistance, while also improving surface smoothness, which helps reduce friction and wear. Zinc plating is mainly used to improve the cylinder block’s corrosion resistance and prevent rust.

Quality Control: Closed-Loop Inspection Throughout the Process

Online Measurement and Closed-Loop Control

The machining center integrates a laser interferometer and a contact probe for 100% online inspection of key dimensions such as cylinder bore diameter and crankshaft bore position. If the detected value deviates from the tolerance zone (±0.01mm), the system automatically corrects the machining path for the next workpiece, achieving a closed loop of “detection-feedback-correction”.

Final Inspection via Coordinate Measuring

The finished cylinder block undergoes rigorous inspection using a coordinate measuring machine (such as the Hexagon PC-DMIS). This primarily tests areas that cannot be measured by vernier calipers, micrometers, or ordinary height gauges, generating a comprehensive dimensional data report.

Conclusion of cnc engine block machining

From stainless steel material selection to 3-axis roughing, 5-axis finishing, and micron-level precision finishing via EDM, our company has built a complete technological barrier with “0.01mm accuracy” as its core. This technology has been applied in fields such as aero-engines, high-performance racing cars, and industrial gas turbines, providing customers with lighter, more durable, and more efficient power solutions. In the future, with the integration of AI process optimization and ultra-precision technology, our company Weldo will continue to lead stainless steel cylinder block manufacturing to even higher standards.

FAQ of cnc engine block machining

What level of precision can be achieved in CNC machining of engine blocks?

CNC machining of engine cylinder blocks offers high precision, with dimensional accuracy in key areas reaching ±0.01 mm or even higher. Computer-controlled machine tools, combined with advanced cutting tools and measuring systems, ensure precise machining of components such as cylinder bore diameters, guaranteeing efficient engine operation.

What materials are commonly used in CNC machining of engine cylinder blocks?

Common materials include cast iron (gray cast iron, ductile iron) and aluminum alloys. Gray cast iron offers vibration damping, wear resistance, and good thermal conductivity; ductile iron boasts superior strength and ductility; aluminum alloys are lightweight and improve fuel efficiency. Material selection depends on engine performance, cost, and vehicle model.

How long does it take to complete the CNC machining of an engine cylinder block?

Machining time varies depending on the complexity of the cylinder block design, the number of machining features, machine tool type, and process parameters. Rough machining and partial finishing of a simple cylinder block may be completed in a few hours, while complex cylinder blocks may require tens of hours or even longer for all processes.

What are the key steps in CNC machining of engine cylinder blocks?

The key steps include blank preparation, clamping and positioning, rough machining, semi-finishing, and finishing. After the blank is clamped and positioned, rough machining removes excess material, semi-finishing prepares the way for finishing, and finishing ensures the final dimensions and surface quality.

How to ensure the quality of the engine block after CNC machining?

Strictly review and simulate the program before machining; select appropriate tools and check and replace them regularly; monitor dimensions in real time during machining; after machining, comprehensively inspect dimensions and surface roughness and perform non-destructive testing to ensure the cylinder block meets standards.