Cnc machining prototyping plays a decisive role in transforming product concepts into validated, manufacturable designs with speed, accuracy, and cost control.

What Is CNC Machining Prototyping? Definition and Material Overview

Cnc machining prototyping refers to the use of CNC milling, turning, and drilling technologies to produce functional prototypes directly from CAD data. Unlike additive manufacturing, cnc machining prototype uses production-grade materials, making it ideal for testing real-world performance, tolerances, and assembly fit.

Main Material Categories in CNC Machining Prototyping

A professional cnc machining prototype service typically supports a wide range of materials:

Metal Materials

- Aluminum alloys (6061, 7075, 2024) – lightweight, easy to machine

- Stainless steel (304, 316, 17-4PH) – strength and corrosion resistance

- Carbon and alloy steel (1018, 4140) – structural and load-bearing tests

- Titanium (Grade 5) – aerospace and medical prototyping

- Brass and copper – electrical and thermal components

Plastic and Engineering Materials

- ABS – low-cost functional prototypes

- POM (Delrin) – precision gears and moving parts

- PA / Nylon – wear-resistant mechanical components

- PEEK – high-temperature and chemical resistance

- PTFE – low friction and sealing applications

Cnc machining prototyping allows engineers to evaluate material behavior before mass production.

10 Critical Considerations in CNC Machining Prototyping

Successful cnc machining prototyping depends on more than fast cutting. Below are ten essential considerations.

- Design intent clarity – Define whether the prototype is for form, fit, or function

- Tolerance realism – Avoid production-level tolerances too early

- Material availability – Select readily available prototype materials

- Surface finish requirements – Specify only what is necessary

- Wall thickness control – Prevent deformation and vibration

- Feature accessibility – Design features reachable by CNC tools

- Assembly interfaces – Validate mating and alignment early

- Revision management – Control drawing versions strictly

- Cost vs. iteration speed – Balance precision and iteration frequency

- Supplier feedback – Use DFM input from cnc machining prototype experts

Addressing these points significantly reduces rework and development delays.

How to Choose the Right Prototype Material for CNC Machining

Material selection is one of the most strategic decisions in cnc machining prototyping.

Match Material to Prototype Purpose

- Concept validation → ABS or aluminum

- Functional testing → PA, POM, or 6061 aluminum

- Load or stress testing → 7075 aluminum or steel

- Thermal testing → PEEK or stainless steel

- Chemical resistance → PTFE or PEEK

Consider Machinability and Lead Time

A good cnc machining prototype supplier will recommend materials that:

- Machine efficiently

- Maintain dimensional stability

- Reduce tool wear

- Lower overall prototype cost

Selecting production-like materials too early may increase cost without adding value.

When Is the Right Time to Use CNC Machining Prototyping?

Understanding the correct timing for cnc machining prototype maximizes ROI.

Ideal Stages for CNC Machining Prototyping

- After initial CAD design is completed

- Before tooling investment (molds or dies)

- During engineering validation testing (EVT)

- Prior to design freeze

- Before pilot or low-volume production

Cnc machining prototyping bridges the gap between digital design and full-scale manufacturing.

The Importance and Value of CNC Machining Prototyping

Technical Importance

- Validates tolerances and GD&T

- Confirms material performance

- Identifies machining risks early

- Improves final product quality

Business Value

- Reduces time to market

- Prevents costly tooling errors

- Accelerates investor and customer approval

- Supports agile product development

For high-precision industries, cnc machining prototype is not optional—it is essential.

CNC Machining Prototyping vs Other Prototyping Methods

| Method | Accuracy | Material Options | Functional Testing |

|---|---|---|---|

| CNC machining prototyping | High | Production-grade | Excellent |

| 3D printing | Medium | Limited | Moderate |

| Hand fabrication | Low | Limited | Poor |

Cnc machining prototype delivers the closest representation of final production parts.

Cost Factors in CNC Machining Prototyping

Key cost drivers include:

- Material type and size

- Machining time and complexity

- Tolerance requirements

- Surface finishing

- Quantity and revision frequency

Cost optimization strategies:

- Simplify non-critical features

- Use common material grades

- Combine features where possible

- Apply DFM recommendations early

An experienced cnc machining prototype partner helps manage these factors efficiently.

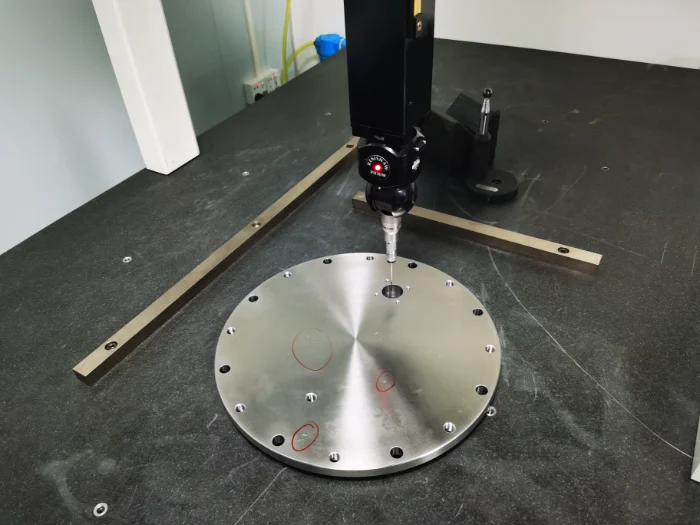

Quality and Confidentiality in Prototype Machining

Professional cnc machining prototype services include:

- First article inspection (FAI)

- Dimensional inspection reports

- Surface finish verification

- Non-disclosure agreements (NDA)

- Secure handling of CAD files

Confidentiality is critical for startups, OEMs, and new product launches.

Scaling from CNC Machining Prototyping to Production

One major advantage of cnc machining prototype is scalability. The same supplier can:

- Refine machining strategies

- Optimize cycle times

- Transition to low-volume production

- Support bridge manufacturing

This continuity reduces technical and supply chain risk.

Final Thoughts and Next Steps

Cnc machining prototyping is a strategic tool for validating design, material, and manufacturability before committing to mass production. By choosing the right materials, timing, and supplier, companies can significantly reduce risk while accelerating product development.

If you are looking for a reliable partner for cnc machining prototyping with rapid turnaround, production-grade materials, strict NDA protection, and engineering support, Weldo Machining offers comprehensive prototyping solutions, technical consultation, and competitive pricing. Contact us to discuss your prototype requirements and receive a detailed quotation.