The demand for accurate cnc plastic machining prototype cost analysis continues to grow as industries rely on plastic components in aerospace, medical devices, electronics, automation, and precision prototypes. Understanding cnc plastic machining prototype cost helps manufacturers improve part performance, reduce waste, and optimize production budgets. This guide explains all cost factors, compares materials, reviews cnc plastic machining prototype price ranges, and introduces global CNC plastic standards with real application examples.

Why CNC Plastic Machining Prototype Matters

Plastic CNC machining supports functional prototypes, lightweight structures, and high-precision components across nearly all industries. Knowing each material’s behavior and cost impact allows engineers to select the best option while controlling cnc plastic machining prototype cost.

Key Benefits

- Tight tolerance capability

- Excellent wear resistance and chemical resistance

- Fast machining cycles with low tool wear

- Wide material selection for mechanical, optical, and electrical parts

CNC Plastic Materials & Their Application Parts

Below are the most common global plastic standards used in CNC machining, each influencing cnc plastic machining prototype cost.

ABS (Acrylonitrile-Butadiene-Styrene)

Features: Easy to machine, cost-effective, good toughness

Typical machined application parts:

- Consumer electronics housings

- Remote-control shells

- Automotive dashboard prototype pieces

- Light structural brackets

- General-purpose enclosures

ABS often results in one of the lowest cnc plastic machining prototype cost ranges.

PC (Polycarbonate)

Features: High strength, optical clarity

Typical machined application parts:

- Transparent protective covers

- Aerospace indicator windows

- Machine vision housings

- Medical display covers

- Impact-resistant guards

Higher toughness slightly increases cnc plastic machining prototype price.

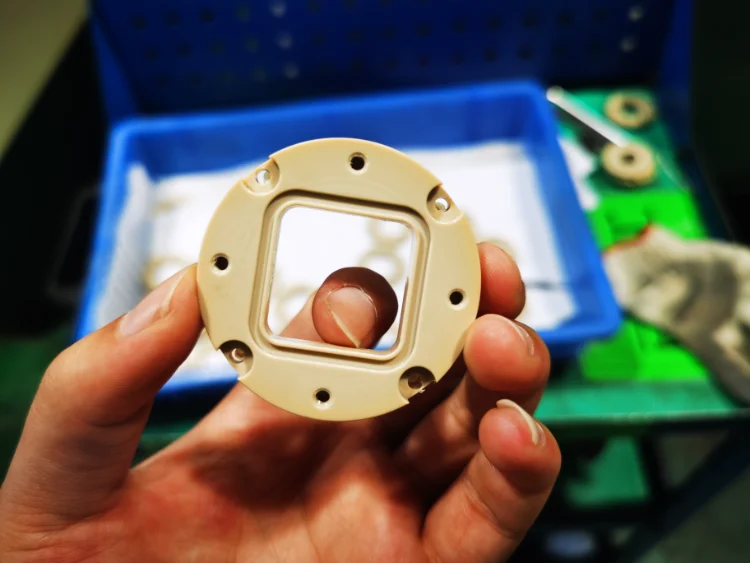

POM / Acetal / Delrin

Features: High precision, low friction, excellent stability

Typical machined application parts:

- Precision gears

- Bearings & bushings

- Robotic sliders

- Valve components

- Mechanical guide blocks

POM provides excellent tolerances with moderate cnc plastic machining prototype cost.

Nylon (PA6, PA66)

Features: Strong, durable, excellent impact resistance

Typical machined application parts:

- Wear pads

- Pulley wheels

- Cable clamps

- Industrial spacers

- Structural sliders

Moisture absorption may affect tolerance, influencing cnc plastic machining prototype price.

PTFE (Teflon)

Features: Near-zero friction, extreme chemical resistance

Typical machined application parts:

- Lab equipment components

- Valve seats

- Insulator washers

- Fluid sealing rings

- Anti-corrosion fittings

PTFE’s softness requires slower machining → higher cnc plastic machining prototype cost.

PEEK (Polyetheretherketone)

Features: Aerospace-grade engineering plastic, high-temperature capability

Typical machined application parts:

- High-temperature bushings

- Aircraft and UAV housings

- Semiconductor tooling

- Medical trial implants

- Oil & gas structural parts

PEEK machining difficulty makes it one of the highest cnc plastic machining prototype price tiers.

PMMA (Acrylic)

Features: Excellent transparency and optical polishability

Typical machined application prototype parts:

- Indicator covers

- Light guides

- Display windows

- Optical prototype blocks

- Transparent testing housings

Requires careful machining to avoid cracks.

UHMW-PE

Features: Extremely tough, high wear resistance

Typical machined application parts:

- Conveyor wear strips

- Dock bumpers

- Impact plates

- Food-grade machinery components

- Sliding structural pads

Toughness leads to higher cnc plastic machining prototype cost.

PEI (Ultem)

Features: High heat resistance, high strength

Typical machined application parts:

- Semiconductor machine brackets

- Aerospace insulation housings

- High-temp connectors

- Medical device components

- Electrical insulators

Often used where strength is critical.

PVC

Features: Chemically stable, inexpensive, well-balanced

Typical machined application parts:

- Fluid-handling fittings

- Prototype valves

- Electrical junction housings

- Pump system components

- Outdoor enclosures

PVC generally offers low cnc plastic machining prototype price.

PP (Polypropylene)

Features: Chemical-resistant, flexible, lightweight

Typical machined application parts:

- Laboratory caps and connectors

- Medical consumable prototypes

- Fluid-handling system parts

- Light-duty hinges

- Industrial testing fittings

A cost-friendly choice for chemical applications.

Key Factors Affecting CNC Plastic Machining prototype Cost

1. Geometry complexity

Thin walls, deep pockets, small radii, undercuts → higher cnc plastic machining prototype cost.

2. Tolerance requirements

- ±0.005 inch (standard plastics)

- ±0.002 inch (POM/PC)

- ±0.001 inch (PEEK precision parts)

Higher precision = higher cnc plastic machining prototype price.

3. Machine type

- 3-axis (lowest cost)

- 4-axis (medium)

- 5-axis (highest cost)

4. Batch size

Prototypes cost more per piece; volume orders reduce cost.

5. Surface finishing

Polishing, sanding, vapor polishing (Acrylic), painting → increases cnc plastic machining prototype cost.

Typical CNC Plastic Machining Prototype Price Ranges

Simple parts (ABS/POM)

$5–$20 per piece

Medium-complexity parts (PC/Nylon/PMMA)

$20–$80 per piece

High-performance parts (PEEK/PTFE/PEI)

$80–$300+ per piece

These values reflect average cnc plastic machining prototype price across global markets.

How to Reduce CNC Plastic Machining Prototype Cost

- Use machinable plastics (ABS, POM) for early-stage prototypes

- Avoid unnecessary thin walls and sharp corners

- Optimize tolerances only where performance requires

- Increase quantities to reduce setup cost

Industries Using CNC Plastic Machined Parts

- Aerospace lightweight structures

- Medical device housings

- Electronic enclosures

- Automotive interior components

- Food processing & automation equipment

- Chemical-resistant fittings

Why Choose Weldo Machining

Weldo provides:

- Multi-axis CNC machining

- Full material selection: ABS, PC, PEEK, PTFE, POM, PA, UHMW-PE, PMMA, PEI, PVC, PP

- Fast prototypes + mass production

- Tight tolerances and quality inspection

- Competitive cnc plastic machining prototype cost for global customers

if you want to know more details about cnc plastic machining prototype or get instant quote,you can feel free to contact with us.