Understanding cnc turning parts price is essential for buyers sourcing precision cylindrical components for automotive, aerospace, medical, industrial machinery, and electronics applications. CNC turning is one of the most efficient machining processes for round, shaft-type, and rotational parts, but the final cnc turning parts price can vary significantly depending on material, geometry, tolerance, quantity, and finishing requirements.

This guide explains how cnc turning parts price is calculated, which factors matter most, typical price ranges, and how to reduce total cost without compromising quality.

What Is CNC Turning and Why Price Matters

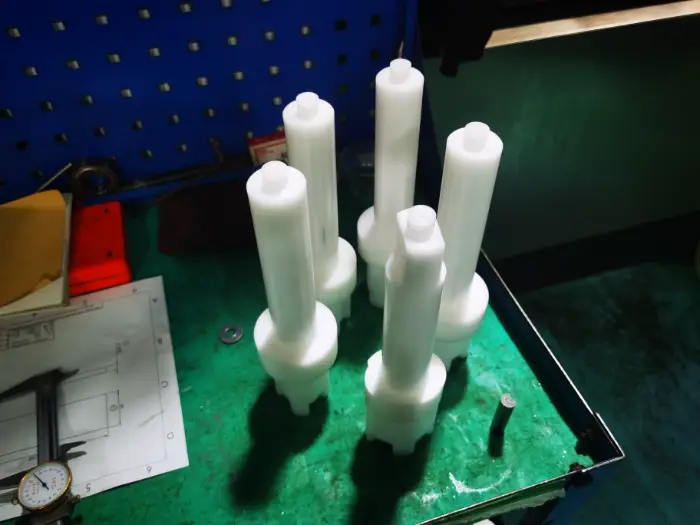

CNC turning uses computer-controlled lathes to remove material from rotating workpieces, producing accurate circular features such as shafts, bushings, pins, sleeves, and threaded parts. Because the process is highly automated, cnc turning parts price is often lower than CNC milling for similar-sized components, especially in medium to high volumes.

However, cnc turning parts price is not fixed. Understanding the pricing model allows buyers to make smarter design and sourcing decisions.

Key Factors That Affect CNC Turning Parts cost

Material Selection

Material is one of the largest contributors to cnc turning parts price.

- Aluminum (6061, 7075): Low machining resistance, lower cost

- Carbon steel (1018, 1045): Moderate price, good machinability

- Stainless steel (304, 316, 17-4PH): Higher cost and longer machining time

- Titanium alloys: High material and machining cost

- Engineering plastics (POM, PTFE, PEEK): Material-dependent pricing

Harder materials increase tool wear and machining time, raising cnc turning parts price.

Part Geometry & Complexity

Simple cylindrical parts have a much lower cnc turning parts price than complex geometries.

Price increases when parts include:

- Multiple diameters and steps

- Deep grooves and undercuts

- Tight internal bores

- Precision threads or micro-features

- Secondary milling operations (turn-mill parts)

The more tool changes and toolpaths required, the higher the cnc turning parts price.

Tolerances & Precision Requirements

Precision directly affects cnc turning parts price.

- Standard tolerance: ±0.05–0.10 mm

- High-precision tolerance: ±0.01–0.02 mm

- Ultra-precision tolerance: ±0.005 mm

Tighter tolerances require slower feeds, better tooling, additional inspection, and sometimes temperature-controlled machining, all of which increase cnc turning parts price.

Surface Finish Requirements

Surface finish impacts both appearance and function.

Common finishes include:

- As-machined

- Polishing

- Brushing

- Anodizing

- Passivation

- Plating

Cosmetic or functional finishing can add 10–50% to the total cnc turning parts price depending on process and parts size.

CNC Turning Parts Price vs CNC Milling Cost

In many cases, cnc turning parts price is more competitive than milling.

When Turning Is Cheaper

- Round or axis-symmetric parts

- Long shafts or rods

- Large batch production

- Simple stepped geometries

When Milling Is Needed

- Complex prismatic features

- Flat surfaces or pockets

- Multi-axis holes

Hybrid turn-mill machining combines both but increases cnc turning parts price compared to pure turning.

Volume & Batch Size Impact on CNC Turning Parts Price

Prototype & Small Batch (1–20 pcs)

- Higher unit cnc turning parts price

- Setup and programming cost spread over fewer parts

- Ideal for testing and validation

Medium Volume (50–500 pcs)

- Optimal balance between cost and flexibility

- Lower unit cnc turning parts price

- Stable production consistency

High Volume (1000+ pcs)

- Lowest unit cnc turning parts price

- Requires stable design and long-term planning

Batch quantity is one of the fastest ways to reduce cnc turning parts price.

Typical CNC Turning Parts Price Range

| Part Type | Material | Approx. Price (USD/pc) |

|---|---|---|

| Simple shaft | Aluminum | $5 – $15 |

| Precision pin | Steel | $8 – $25 |

| Threaded bushing | Stainless steel | $15 – $40 |

| Complex turned part | Titanium | $40 – $150 |

| Plastic turned part | POM / PTFE | $6 – $30 |

Actual cnc turning parts price depends on tolerances, quantity, and finishing.

Cost Structure Behind CNC Turning Parts Price

Material Cost

Raw material cost varies by alloy and global market conditions.

Machining Time

Cycle time is the main cost driver in cnc turning parts price.

Tooling & Tool Wear

Harder materials consume tools faster.

Setup & Programming

Higher impact on small-batch production.

Inspection & Quality Control

Tight tolerances increase inspection time and cost.

How to Reduce CNC Turning Parts Price

Optimize Part Design

- Avoid unnecessary tight tolerances

- Use standard diameters and threads

- Minimize secondary operations

Choose the Right Material

Use aluminum or machinable steel when performance allows.

Increase Batch Quantity

Higher volume significantly lowers unit cnc turning parts price.

Simplify Surface Finish

Only specify required functional finishes.

Use DFM Support

Design-for-manufacturability reviews often reduce cnc turning parts price by 10–30%.

Industries Using CNC Turning Parts

- Automotive: shafts, pins, bushings

- Aerospace: fasteners, connectors, sleeves

- Medical: cylindrical device components

- Industrial machinery: spacers, rollers, couplings

- Electronics: precision housings and connectors

Each industry places different demands on cnc turning parts price and precision.

Conclusion

The cnc turning parts price depends on material choice, part geometry, tolerances, volume, and finishing requirements. By understanding these factors and applying smart design and sourcing strategies, buyers can achieve high-precision turned parts at competitive prices. CNC turning remains one of the most cost-effective manufacturing methods for cylindrical components across many industries.if you want know more details or get a quote,please feel free to contact with us.