Deburring in machining is an essential finishing step that removes sharp edges and unwanted burrs created during CNC milling, turning, drilling, tapping, and other manufacturing processes. Because burrs can compromise functionality, safety, and accuracy, deburring in machining ensures that components meet the required quality standards for assembly, performance, and durability. Understanding which materials form burrs, how chamfering works, and which tools are used for edge preparation helps manufacturers and engineers make informed finishing decisions.

Why Deburring in Machining Is Important

Even a small burr can cause serious issues—misalignment, premature wear, electrical interference, sealing failure, or operator injury. Deburring in machining improves dimensional consistency, protects sensitive edges, and ensures components perform as intended in high-precision industries.

Materials That Commonly Require Deburring

Metals

- Aluminum – Prone to micro-burrs during high-speed cutting; used in electronics, brackets, covers, and precision frames.

- Stainless steel – Harder burrs that require stronger tools; common in medical, food-processing, and valve components.

- Carbon steel & alloy steel – Produces aggressive burrs; used for gears, shafts, automotive fittings, and bearing housings.

- Brass & copper – Must have clean edges for electrical conductivity; used in contact terminals and inserts.

Plastics

- ABS, POM, Nylon, PEEK, PC – Develop light fuzz burrs; used in consumer goods, medical prototypes, and mechanical guides.

Deburring in machining ensures these materials remain functional and safe during assembly and service.

Deburring Techniques in CNC Manufacturing

Manual Deburring

Blades, scrapers, files, abrasive stones—ideal for prototypes or deep pockets that machines cannot easily reach.

Mechanical Deburring

Abrasive wheels, tumbling, vibratory finishing, and rotary brushes are used for medium-to-large batches requiring uniform edge control.

Chamfering and Edge Rounding

Chamfering removes sharp corners while rounding softens the edge transition. It enhances assembly smoothness, sealing reliability, and fatigue resistance.

CNC-Integrated Deburring in Machining

Automated chamfer passes, corner-rounding tools, and deburring mills reduce labor, improve repeatability, and maintain edge consistency.

Thermal or Brush Deburring

Thermal deburring removes internal burrs in passages, while brush deburring ensures fine finishing for electronics and aerospace components.

Common Tools Used for Chamfering & Edge Processing

Chamfering tools are an important part of deburring in machining because they control the edge geometry accurately:

V-Shaped Chamfer Mills

Creates consistent 45° or 60° chamfers; widely used for aluminum, steel, and stainless steel.

Carbide Deburring Tools

High-strength tools suitable for stainless steel, titanium, and other hard metals.

Countersink Cutters

Used for screw holes and edge refinement around drilled openings.

Corner-Rounding End Mills

Used to soften edges and reduce stress concentration on structural components.

Deburring Wheels & Rotary Brushes

Ideal for smoothing aluminum and brass edges without altering dimensions.

These tools ensure chamfers remain uniform and stable across prototypes and mass-production runs.

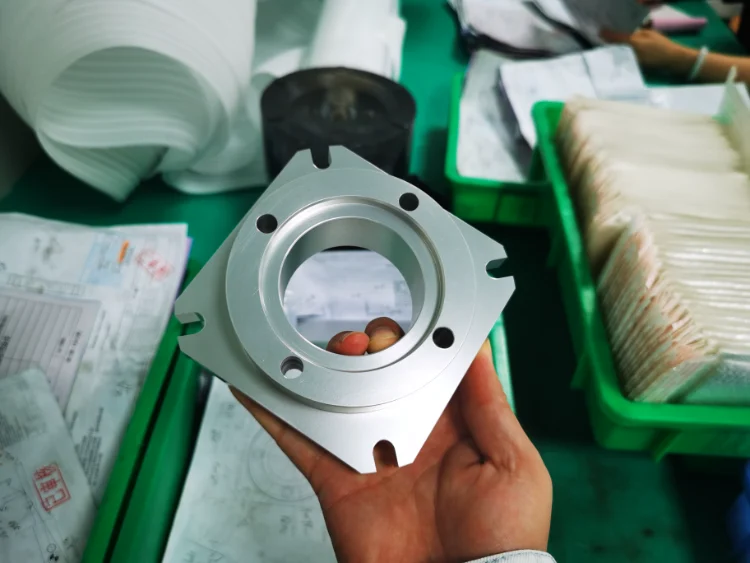

Parts That Commonly Need Edge Treatment

- Gears, pulleys, splines

- Shafts, pins, axles

- Hydraulic manifolds and valve bodies

- Frames, brackets, machine covers

- Electronic device housings

- Aerospace and medical components

Deburring in machining ensures these parts maintain accurate mating surfaces and safe handling.

How to Choose the Right Deburring Method

Based on Material

- Aluminum: CNC chamfering + brush finishing

- Stainless steel: mechanical wheel deburring

- Brass/copper: fine manual deburring for clean conductive edges

- Plastics: low-heat blade finishing to avoid melting

Based on Application

- Aerospace & medical: strict edge uniformity and reliable surface integrity

- Automotive: consistent deburring for moving components

- Electronics: smooth conductive edges to prevent micro-arcing

Based on Geometry

Internal channels, small holes, thin walls, and intersecting cavities require more precise deburring in machining to avoid damage or deformation.

Best Practices for Quality Deburring

- Define chamfer or radius size in engineering drawings

- Use radius-friendly transitions to reduce burr formation

- Coordinate finishing requirements early

- Use controlled toolpaths for high-volume production

- Avoid over-rounding that may alter the mating surface

Conclusion

Deburring in machining plays a vital role in ensuring quality, safety, and consistent performance in CNC-manufactured components. With the right combination of tools, techniques, and material-specific strategies, manufacturers can achieve precise edges and reliable functionality across prototypes and mass production. For expert machining support, advanced chamfering solutions, and high-quality finishing services, contact Weldo Machining for professional guidance and fast quotations.

FAQ of Deburring in Machining

Can deburring improve coating adhesion?

Yes—clean edges allow anodizing, plating, or painting to bond more evenly.

Is machine-integrated deburring more accurate than hand deburring?

Yes, CNC-based deburring ensures uniform edges and lower human variation.

Do burrs affect sealing surfaces?

Even small burrs can cause leaks in hydraulic or pneumatic components.

Which parts benefit most from edge rounding?

Structural components under load, as rounded edges reduce stress risers.

Can deburring be customized for medical-grade parts?

Yes—medical components often need finer deburring with strict surface validation.