5 axis cnc machining service

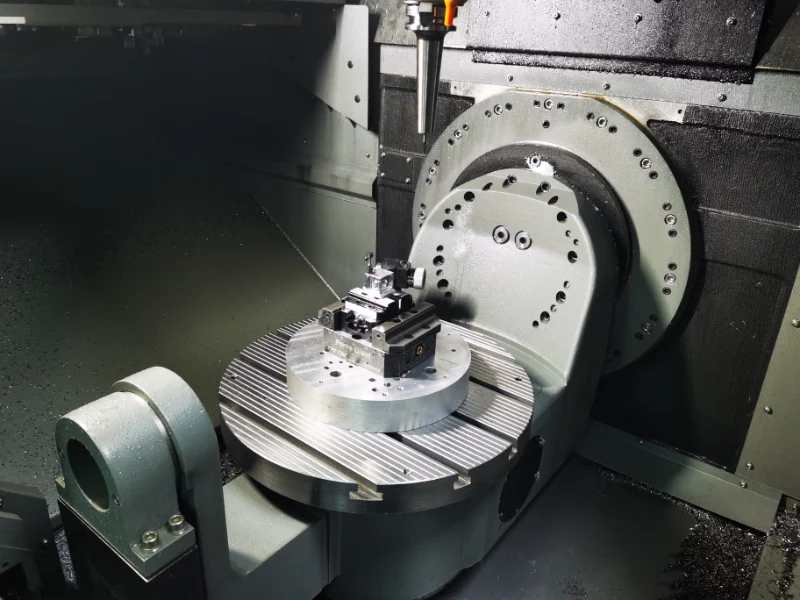

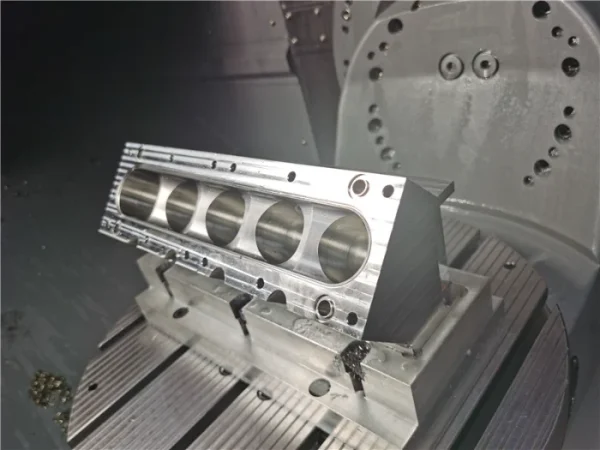

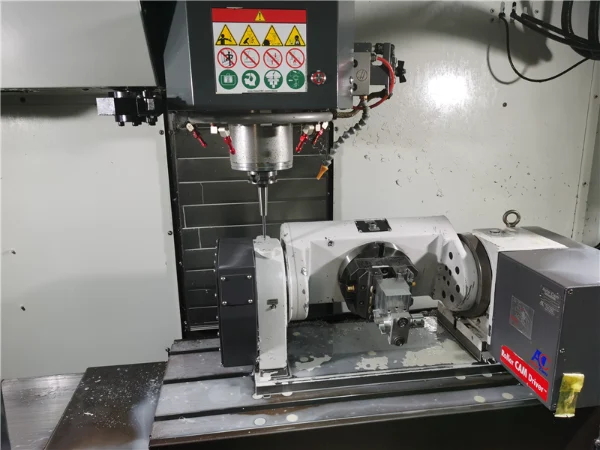

5-axis CNC machining unlocks the manufacturing of complex surfaces, irregular structures, and micro-hole processing with precision down to 0.001mm. Whether for aerospace titanium alloy blades, automotive engine upgrades, micro-threads in medical implants, or lightweight monolithic components, our 5-axis technology achieves 5-face machining in a single setup through dynamic tool compensation and intelligent collision detection. This boosts efficiency by 60% while maintaining surface roughness below Ra 0.4.

5 axis cnc machining service with Weldo

We possess extensive machining expertise in five-axis processing, with years of specialized experience in selecting materials for components across various equipment configurations and operational environments. We achieve a balanced approach between durability, reliability, and cost efficiency. Approximately 100 material options are available for your selection, with tolerances achievable down to 0.001 inch.

What is 5 axis cnc machining ?

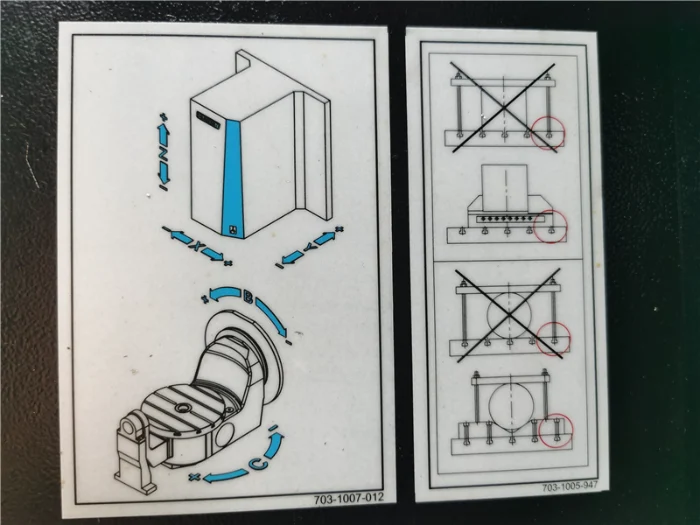

Five-axis CNC machining achieves high-precision processing of complex surfaces and irregular structures by simultaneously controlling five machine axes (three linear axes X/Y/Z + two rotary axes A/B or C), enabling multi-angle tool or workpiece orientation adjustments.

The tool maintains optimal contact angles with the workpiece surface throughout machining, eliminating precision losses caused by multiple setups required in traditional three-axis machining.

It enables single-setup machining of five-sided components (e.g., all five faces of a cube), making it particularly suitable for complex structures like deep cavities, inclined holes, and curved threads.

5 axis cnc machining material optional

Our 5-axis CNC machining centers boast over a decade of production experience, capable of precision machining and cutting approximately one hundred materials with tolerances as tight as 0.001mm. Below are our commonly used material options for CNC machined parts. Should you require machining of other unique materials, please contact us for further information.

Metal material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

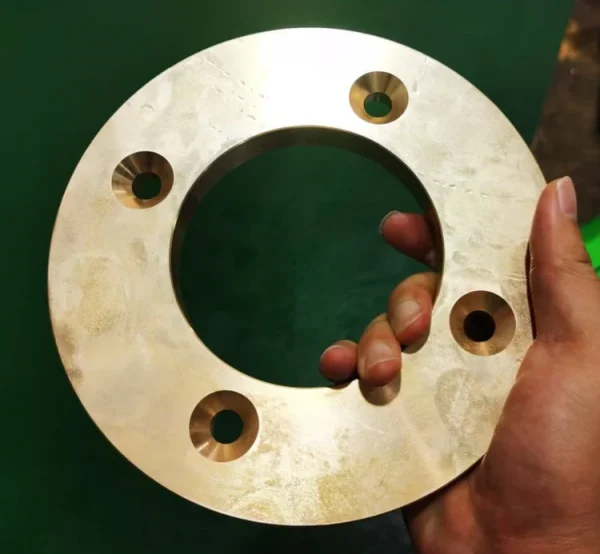

Bronze

Bronze is a copper–tin alloy with good fluidity and corrosion resistance. It has a low melting point (800–900 °C) and varies in color from golden yellow (low tin) to silver-gray (high tin). Bronze is widely used for bearings, gears, valves, sculptures, and marine components such as propellers and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Steel is an iron–carbon alloy (0.1%–1.7% carbon) with added elements such as chromium and nickel. Through composition and heat treatment control, it offers high strength, toughness, wear resistance, and corrosion resistance, and is widely used for bolts, shafts, gears, cutting tools, engine valves, and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

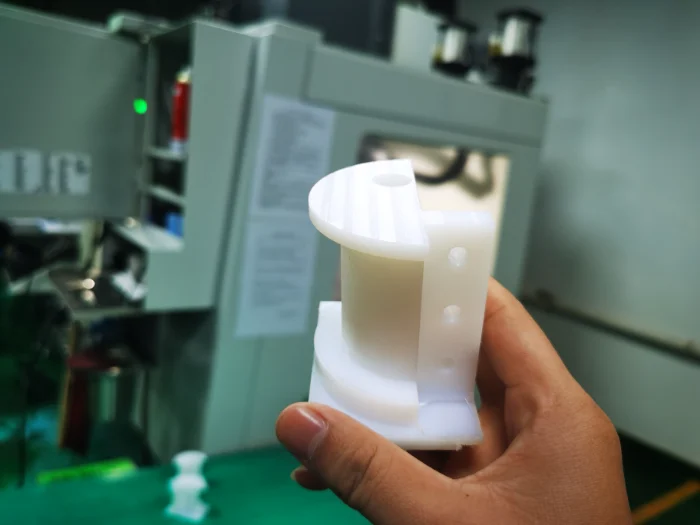

Plastic material :

ABS

ABS combines rigidity, toughness, and good processability, offering excellent impact resistance even at low temperatures. It is suitable for precision parts under moderate loads, such as electronic housings, automotive ducting, and interior and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HIPS

HIPS is a non-crystalline thermoplastic containing 5-15% rubber content, offering both high impact resistance and ease of processing. It features moderate surface hardness, low moisture absorption (0.05-0.7%), low cost, and suitability for complex structures. Widely used in appliance housings, food packaging, automotive interiors, and industrial piping, it replaces metal to meet lightweight and impact-resistant requirements.

Color : black.

Types : Impact-resistant HIPS, Brominated flame-retardant HIPS, Glass-fiber reinforced HIPS.

Surface finish :Polishing ,Sandblasting ,Coating.

Delivery time : 1-5 days.

Surface finishes for 5 axis cnc machining part

Drawing on over a decade of CNC machining expertise and surface treatment processes, Weldo has compiled the following finishing options designed to enhance the surface quality and finish of parts after 5-axis machining. This approach improves component appearance, surface roughness, hardness, and corrosion resistance while effectively masking tool marks.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

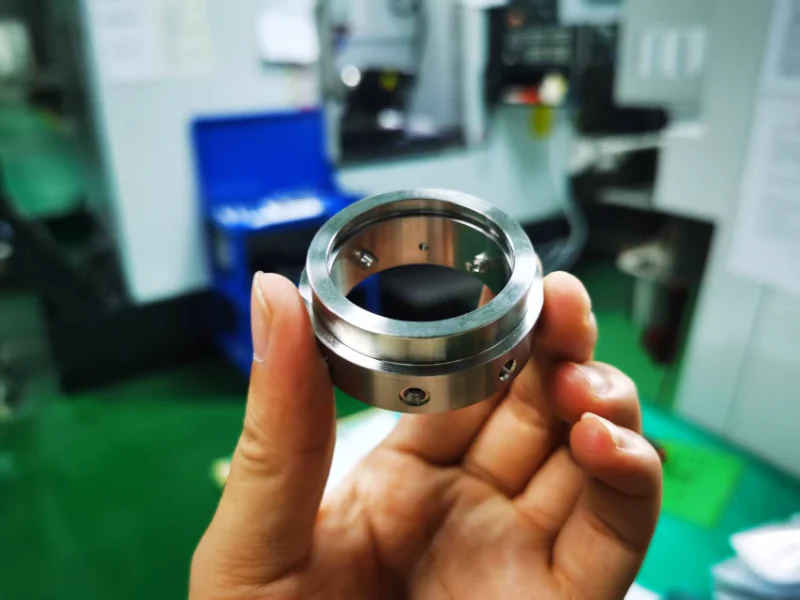

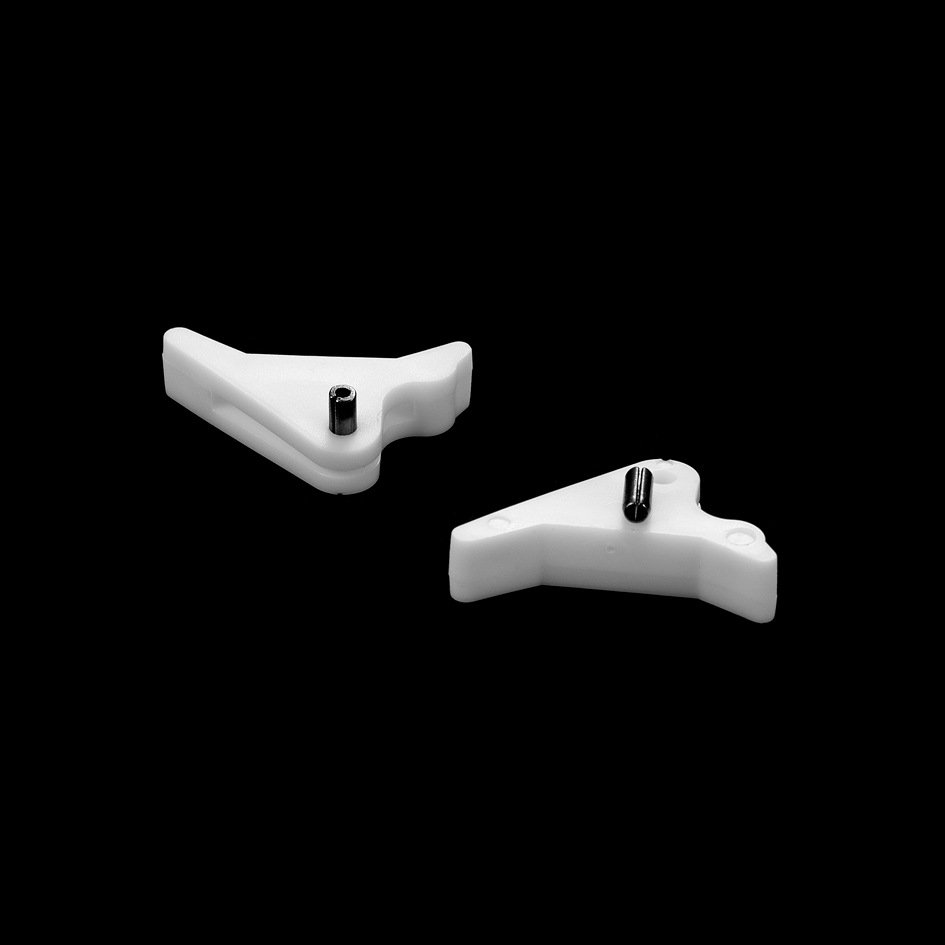

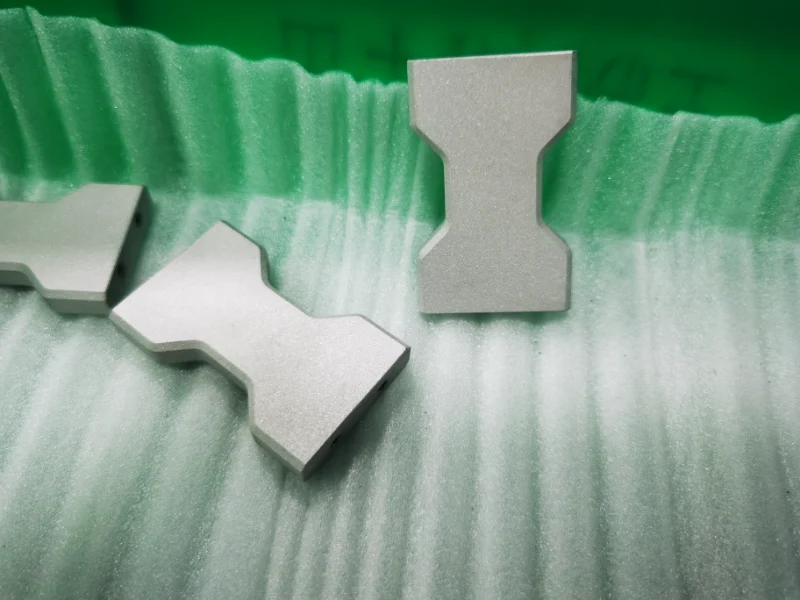

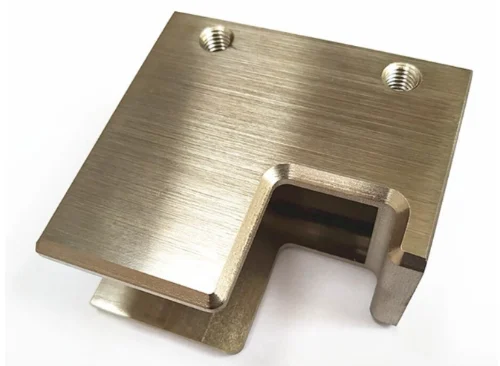

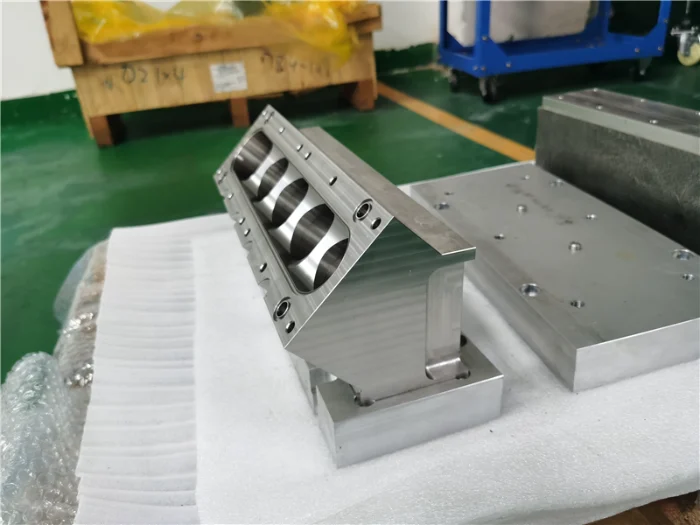

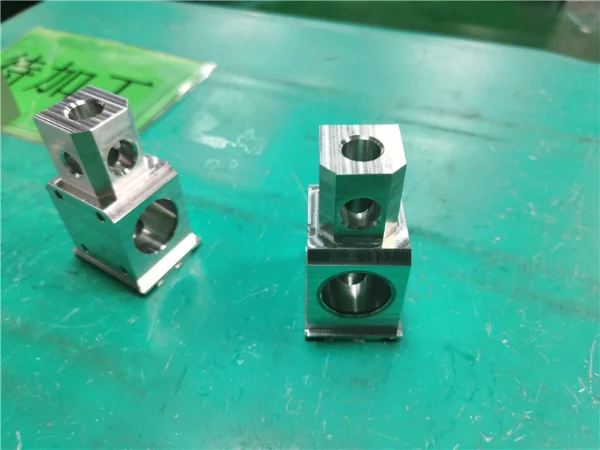

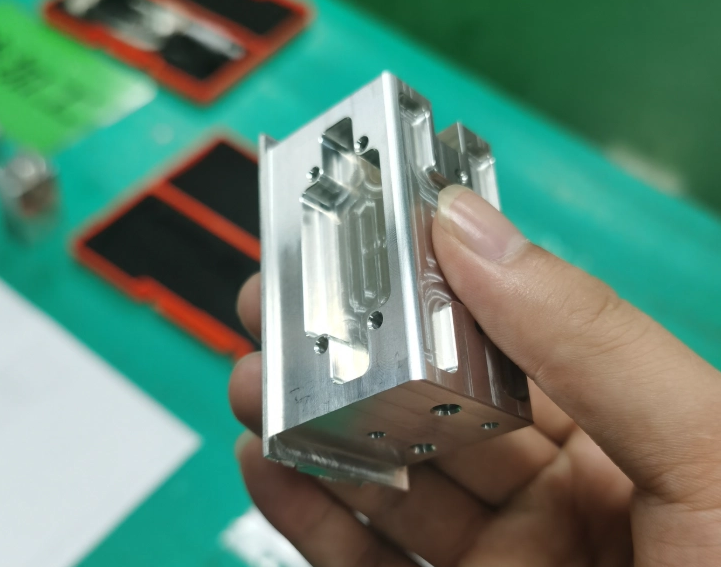

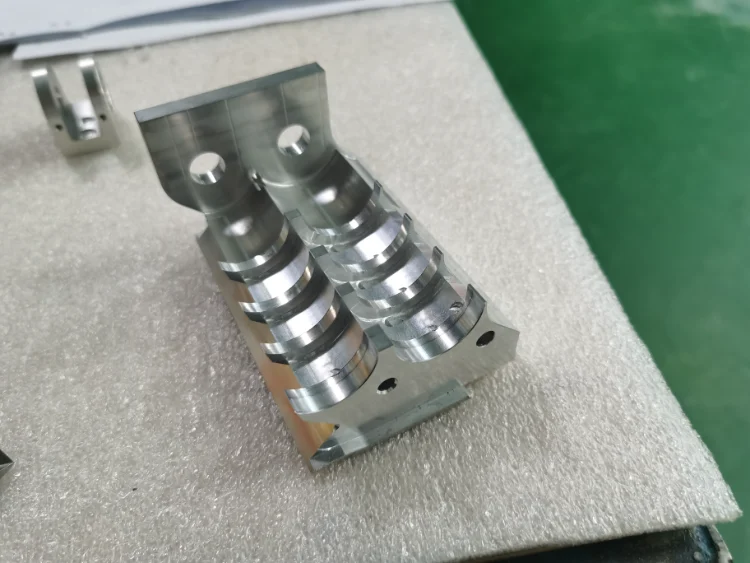

5 axis cnc machining parts

Advantage of 5 axis cnc machining

Higher Efficiency with Fewer Setups

Multiple faces and complex features can be machined in a single setup, reducing setup time and shortening overall cycle time.Improved Accuracy and Consistency

Fewer re-clamps mean less accumulated error, helping maintain tighter positional tolerances and more consistent quality across batches.Better Access to Complex Geometry

Tool orientation can be optimized to reach deep cavities, angled holes, undercuts, and freeform surfaces that are difficult or inefficient in 3-axis machining.Superior Surface Finish and Tool Life

Optimal cutting angles reduce vibration and heat, improving surface finish while lowering cutting forces—often extending tool life and reducing scrap risk.

Application of 5 axis cnc machining part

Aerospace Components

Blisks, impellers, turbine blades, structural brackets, and complex housings that require tight tolerances and multi-surface machining.Medical and Orthopedic Parts

Surgical instruments, implant trial components, cutting guides, and complex polymer/metal parts with precise features and smooth surface requirements.Automotive Performance and Prototype Parts

Engine components, transmission housings, intake manifolds, and prototype parts where complex geometry and fast iteration are critical.Energy and Industrial Equipment Parts

Pump and valve bodies, impellers, compressor components, and precision manifolds requiring multi-angle drilling and complex internal features.

FAQ of 5-axis cnc machining service

What is 5-axis CNC machining? How is it different from 3-axis machining?

5-axis CNC machining refers to adding two rotational axes to the three linear axes (X, Y, and Z), allowing the tool or workpiece to be machined from multiple angles. It can complete the machining of complex surfaces, multi-angle holes, and deep cavity structures in a single setup, improving machining accuracy and reducing cumulative errors caused by multiple setups.

What types of milling cutters are commonly used in 5-axis CNC machining?

Common tools include flat end mills, ball nose end mills, corner radius end mills, tapered end mills, high-feed cutters, indexable milling cutters, and form tools. Different tools are used for roughing, semi-finishing, and finishing operations.

Why are ball nose and corner radius end mills so popular in 5-axis machining?

Because 5-axis machining is widely used for complex surfaces. Ball nose end mills are ideal for surface finishing, while corner radius end mills offer better efficiency and tool life. Tilting the tool in 5-axis machining also improves surface quality.

What are high-feed cutters and indexable cutters mainly used for in 5-axis machining?

They are mainly used for roughing and heavy material removal. Indexable cutters are suitable for large flat areas, while high-feed cutters are ideal for efficient roughing of deep or complex cavities.

How should different cutters be combined in 5-axis machining?

Typically, indexable or high-feed cutters are used for roughing, flat or corner radius end mills for semi-finishing, and ball nose or tapered ball end mills for finishing, with the final choice depending on rigidity and tool access.