Centerless grinding

Precision and efficiency in centerless grinding solutions—achieve zero-error machining! Request a quote today for customized process solutions and cost optimization recommendations.

What is centerless grinding ?

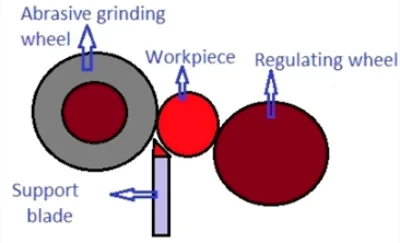

Centerless grinding eliminates the need for traditional fixtures or centers to secure workpieces. The workpiece is positioned between the grinding wheel and the regulating wheel, supported by a lower support plate. The regulating wheel drives the workpiece rotation (via friction) while controlling its axial feed rate. The grinding wheel cuts the workpiece’s outer diameter, achieving high-precision grinding. The workpiece center dynamically shifts during grinding. By adjusting the relative position between the grinding point and the support point, roundness errors are progressively corrected. Roundness errors are typically controlled within 0.005 to 0.01 mm, with surface roughness achievable at Ra 0.1 to 0.025 μm.

Metal material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Plastic material :

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

Centerless grinding capability

The machining capability of non-centering cylindrical grinding is influenced by CNC centerless grinding machines, operators, precision requirements, and materials. The following outlines the approximate ranges for dimensions and precision:

| Indicator | Specific Parameters |

|---|---|

| Machining Accuracy | |

| Roundness | ≤ 0.015 mm |

| Cylindricity | 0.5~2 μm (typical value) |

| Dimensional Accuracy | Up to IT6 grade (approximately ±0.005~0.015 mm), surface roughness Ra 0.16~0.2 μm |

| Maximum Workpiece Dimensions | |

| Diameter | 40–100 mm |

| Length | Maximum grinding length of 1000 mm; length range of 125–210 mm in transverse feed grinding mode |

| Minimum Workpiece Dimensions | |

| Diameter | ≥ 2 mm (minimum diameter) |

| Length | Minimum grinding length of 125 mm in transverse feed grinding mode |

Centerless grinding advantage

High-Efficiency Production

Continuous Machining: Workpieces require no clamping, enabling rapid batch production through through-feed/plunge grinding.

Multi-Part Synchronization: Supports automated production lines, reducing individual part processing time.

High Precision and Consistency

Superior Roundness/Cylindricity: Roundness ≤0.005mm, cylindricity error 0.5–2μm.

Dimensional Stability: Eliminates clamping errors, ideal for high-volume precision machining.

Surface Finish: Roughness below Ra 0.1μm.

Adaptability

Material Versatility: Processes metals, plastics, and high-hardness/brittle materials.

Shape Flexibility: Handles slender shafts, short shafts, stepped/tapered components, thin-walled parts, etc.

Process Stability

Automated Operation: Minimizes human error with low skill dependency.

Dynamic Tuning: Controls vibration through parameter adjustments for enhanced stability .

Cost Efficiency

Long-Term Savings: High efficiency and low scrap rate ensure rapid ROI.

Reduced Post-Processing: High-precision surfaces eliminate polishing/grinding requirements.

Application of centerless grinding

Automotive Manufacturing

Core Components: Precision grinding of high-accuracy parts such as crankshafts, camshafts, drive shafts, and valve stems.

Aerospace

High-Precision Components: Engine shafts, fuel pump housings, satellite components, etc.

Material Adaptability: Titanium alloys, high-temperature alloys, and other difficult-to-machine materials.

Machinery Manufacturing

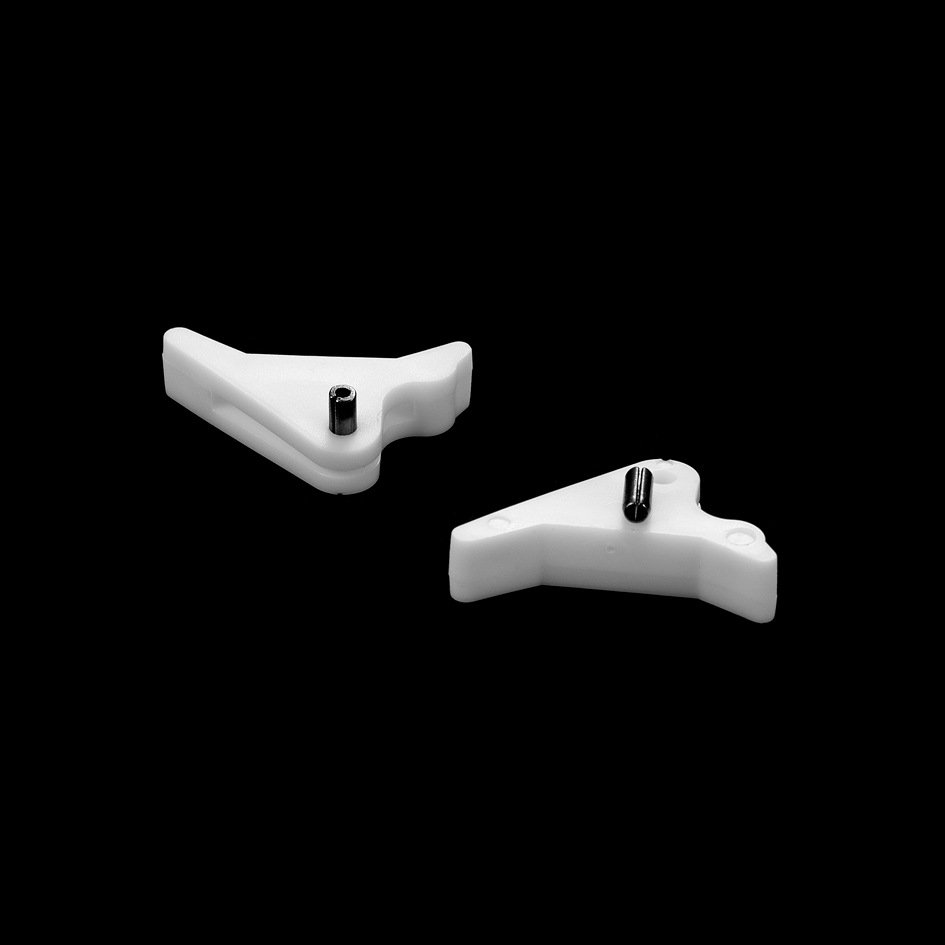

General-purpose components: Shearing tools, end mill shanks, rolling pins, drill bits, etc.

Bearings and Transmission Components

Standard part production: Bearing rollers, needle roller bearings, alloy bushings, etc.

Special Material Processing

Cemented carbide/ceramics: Cutting tools, ceramic rods, and other high-hardness materials.

FAQ of centerless grinding

What is the core difference between centerless grinding and conventional external cylindrical grinding?

Centerless grinding requires no workpiece clamping. The workpiece is driven by guide wheels and ground by the grinding wheel, relying on its own weight or support for positioning. Conventional external grinding requires fixation with centers/chucks, which can cause deformation or clamping errors.

Advantages: Suitable for slender shafts/thin-walled parts, high efficiency, and superior roundness and dimensional consistency.

What workpiece shapes can centerless grinding process?

Primarily rotary parts, typically including:

Long-to-diameter ratio slender shafts (e.g., drive shafts);

Short shafts or parts without center holes (e.g., bearing rollers);

Complex shapes with steps/taper (achieved via plunge grinding);

Thin-walled components (e.g., tubes, with low radial pressure).

Limitations: Not suitable for non-rotating or flat parts.

How is machining accuracy ensured in centerless grinding?

Machine setup: Guide wheel inclination, grinding wheel dressing, support plate height;

Process parameters: Grinding depth and feed rate matched to material hardness;

Cooling and inspection: Adequate coolant prevents thermal deformation, online measurement provides real-time feedback.

Is centerless grinding suitable for high-hardness materials?

Suitable, but adjustments are required:

Grinding wheel: Use CBN or diamond wheels with finer grit (#600-#1000);

Process: Reduce grinding depth, increase feed rate, and use high-pressure coolant for heat dissipation;

Typical Applications: Carbide tools, ceramic bushings, high-temperature alloy turbine shafts.

Summary: Through equipment and process optimization, centerless grinding can efficiently process high-hardness materials, requiring strict temperature control and grinding wheel management.