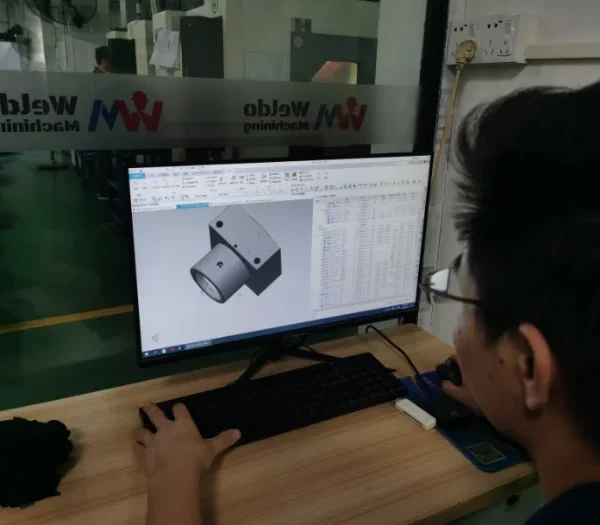

About Weldo machining

Company profile

Founded in 2012, Weldo Machining is a precision manufacturing service provider specializing in multi-axis CNC machining, conventional turning, CNC grinding, and CNC EDM. We offer a one-stop service from design, precision milling and grinding, quality inspection to surface treatment, packaging, and shipping. The company currently employs over 120 professional technicians, operates within its own machining industrial park, and achieves annual sales exceeding 100 million dollars . Our products are widely used in high-end fields such as aerospace, automotive, consumer electronics, industrial equipment, and new energy.

How to cooperate with WELDO Machining

Core Machining Capabilities and Material Coverage

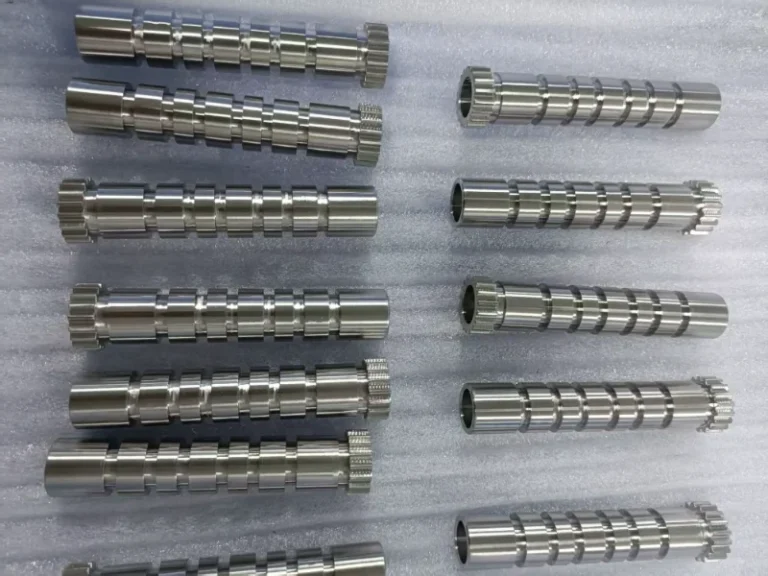

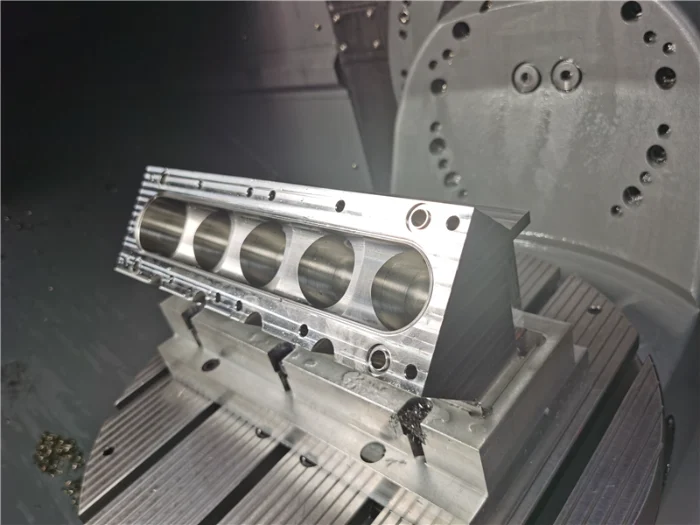

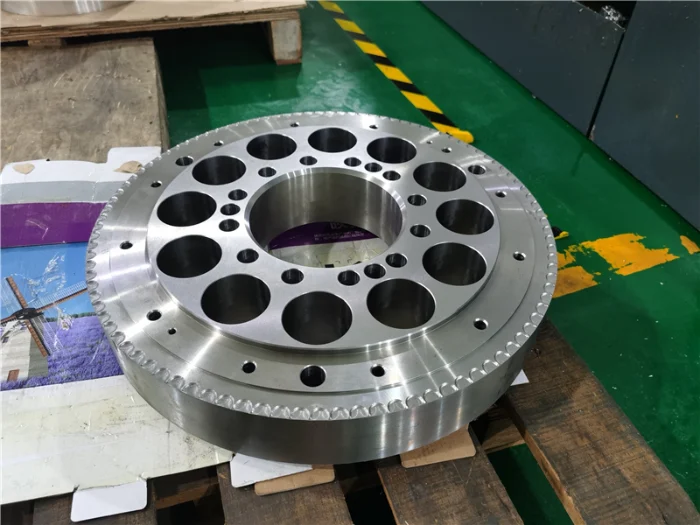

Multi-axis CNC Machining: Supports 3 axis, 4 axis, and 5 axis simultaneous machining, meeting the manufacturing needs of complex curved surfaces and high-precision parts.

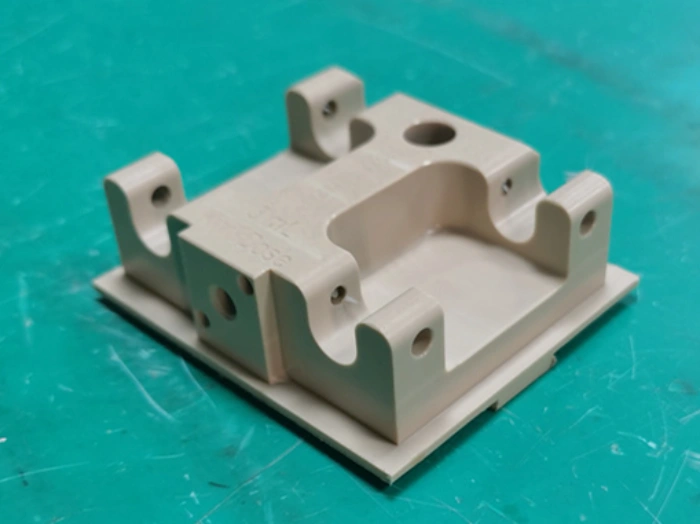

Diverse Processes: Covers conventional cnc milling / turning, CNC grinding, CNC EDM, metal extrusion , injection molding, etc., forming a complete process chain.

Material Coverage:

Metals: Aluminum, stainless steel, copper, bronze, magnesium alloy, titanium alloy, alloy steel, etc.;

Plastics: ABS, PC, PP, PEEK, PMMA, PA, POM, and other engineering plastics.

Surface finish : Offers more than ten surface finish technologies (such as anodizing, electroplating, sandblasting, hard coating, etc.) to enhance the corrosion resistance and aesthetics of parts.

Weldo certification and Customer Protection

We are ISO 9001 quality management system certified and strictly adhere to international processing standards. We employ high-precision testing equipment such as coordinate measuring machines to ensure that the dimensional deviation of parts is controlled within ±0.001mm.

With “protecting customer privacy” as our core principle, we have established a strict confidentiality system, earning the trust of clients in sensitive fields such as aerospace and automotive. We provide full-cycle services from “design to prototyping to mass production to packaging,” helping clients shorten product launch cycles and enhance their market competitiveness.

Why choose Weldo machining to cooperate ?

Choosing Weldo Machining as a precision manufacturing partner offers seven key advantages:

1. Diverse Processes and Full Material Coverage

Multi-axis CNC Machining: Supports three to five axes of simultaneous machining with an accuracy of ±0.001mm, adaptable to complex curved surfaces and irregularly shaped structures.

Material Compatibility: Covers metals such as aluminum and titanium alloys, as well as engineering plastics such as ABS and PEEK, meeting diverse needs.

Surface Treatment: Offers processes such as anodizing and electroplating to enhance the functionality and aesthetics of parts.

2. Rapid Prototyping and Mass Production

CNC Rapid Prototyping: Prototype production completed in 3-5 days, supporting rapid design verification and iteration.

Standard Mass Production: Annual sales exceeding $10 million, with single-batch capacity reaching thousands of units, and stable and controllable delivery times.

Cost Optimization: Mass production reduces unit price, and end-to-end management improves cost-effectiveness.

3. One-Stop Full-Lifecycle Service

Service Closed Loop: From design optimization and prototyping to mass production, quality inspection, packaging, and shipping, simplifying supply chain management.

Flexible Customization: Supports small-batch production starting from 10 pieces, adapting to the needs of industries such as consumer electronics and new energy.

4. Customer Privacy and Long-Term Trust

Data Security: Design files and production data are encrypted throughout the entire process, eliminating concerns about cooperation with sensitive industries.

Reputation Endorsement: Established stable partnerships with leading companies, with case studies covering military, new energy, and other fields.

5. Deep Industry Focus and Rapid Response

Automotive: Compliant with IATF 16949 standards, processing key components such as new energy battery casings.

Consumer Electronics: Provides integrated CNC machining services for metal casings and structural components.

Aerospace: AS9100D certified, processing high-requirement parts such as turbine blades.