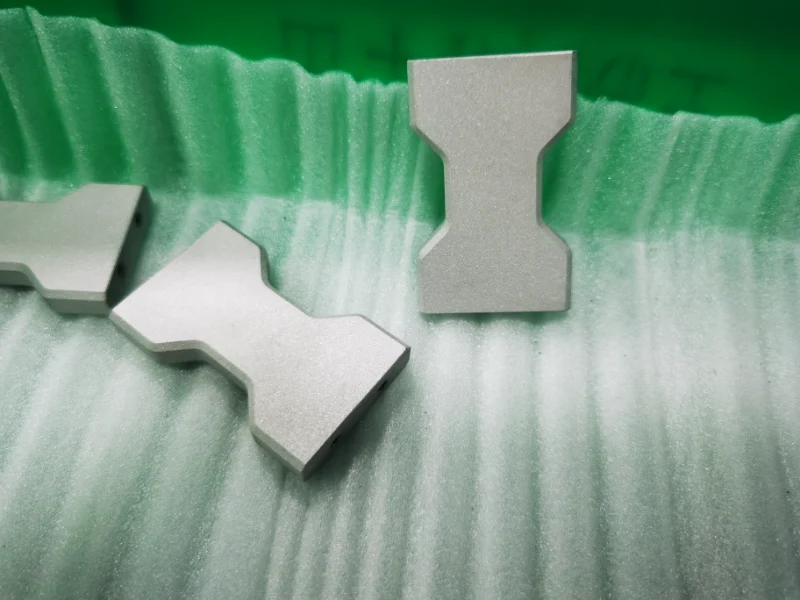

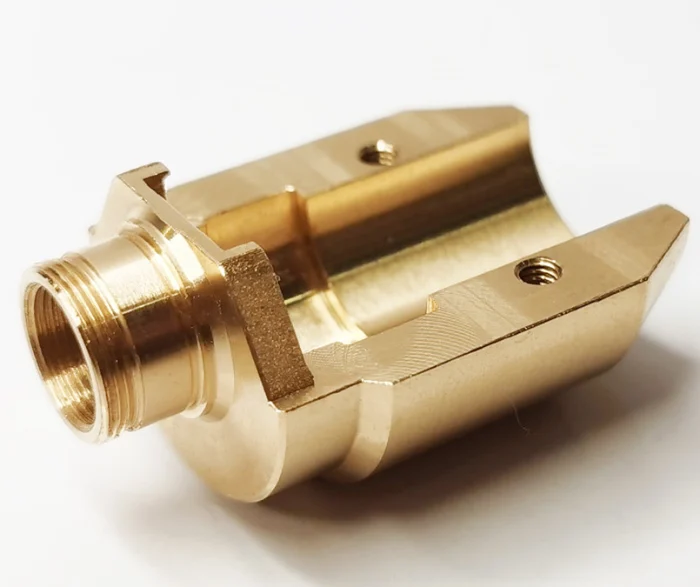

Brass CNC machining

Overview:

CNC brass machining uses computer numerical control (CNC) technology for precision milling, turning, drilling, and cutting brass (a copper-zinc alloy, sometimes with Pb, Al, or Si additions). It produces components meeting design specifications for accuracy, tolerance, and structure. Due to its high precision, stability, and efficiency, it’s widely used in electronics, fluid systems, instrumentation, medical devices, and hardware manufacturing.

Price : 10–150 USD / PCs

Min wall thickness : 0.5 mm

Tolerances : 0.001 inch

Max workpiece part : 2000 mm × 1000 mm × 1000 mm

Other brass types available in Weldo: Free-cutting brass (C360), leaded brass, high-strength brass, naval brass, silicon brass.

Types of brass for cnc machining

C260: Contains 70% copper and 30% zinc, high ductility, and strong versatility.

C360: Contains lead, easy to machine, suitable for mass production.

C37700: Combines strength and machinability, suitable for forging machined parts.

C48500: Contains lead, good machinability and high strength.

C69300: Silicon brass, high strength, corrosion resistance, and excellent machinability.

Applications and Accessories

Electronics Industry: Precision components such as connectors and terminals.

Fluid Systems: Fluid control components such as valves and pipe fittings.

Instruments and Meters: Mechanical parts such as instrument housings and gears.

Medical Equipment: Precision components for surgical instruments and diagnostic equipment.

Hardware Manufacturing: Hardware accessories such as locks and handles.

Features

High Precision: CNC machining achieves precise dimensional control.

Good Stability: Low deformation coefficient of brass, stable component dimensions.

Excellent Machinability: Lead is added to some alloys to reduce machining difficulty.

Highly corrosion-resistant: adaptable to various environmental conditions.

Highly recyclable: environmentally friendly, fully recyclable and reusable.

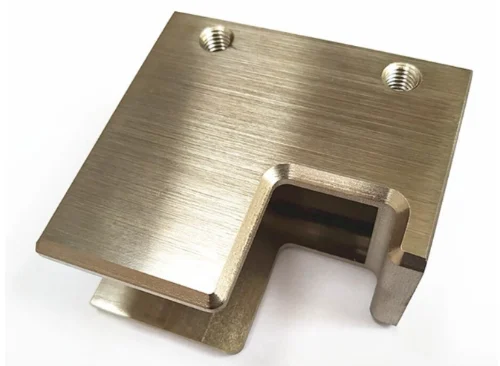

Surface finish for CNC machining parts

Based on over 15 years of CNC machining experience, we have compiled the following list of surface finish processes used for various precision-machined parts made from brass material.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Capability of brass cnc machining in Weldo

Maximum machining size: 2000mm*1000mm*1000mm

Minimum machining size: 5mm*5mm*5mm

Minimum machining diameter: 0.5mm

Minimum tolerance: ±0.01mm

Standard roundness tolerance: ±0.01-0.03mm

Precision roundness tolerance: ±0.003mm

Brass CNC Machining Guide

Pre-machining Preparation

Material Selection: Select the appropriate brass grade (e.g., C260, C360) based on requirements.

Design Evaluation: Evaluate the design feasibility using CAD, considering tool limitations.

Process Development: Plan cutting tools, parameters, paths, etc.

Programming: Convert the design file into a machining program using CAM.

Machine Tool and Tool Preparation

Machine Tool Selection: Select a suitable CNC machine tool for brass machining.

Tool Selection: Select cutting tools according to requirements, ensuring contour accuracy.

Tool Mounting: Securely clamp the tools to prevent loosening.

Machining Process Control

Workpiece Mounting: Accurately and stably clamp the workpiece to avoid movement and vibration.

Parameter Setting: Set appropriate parameters such as cutting speed and feed rate.

Machining Monitoring: Closely monitor the machining process and adjust parameters and tools promptly.

Post-Machining Processing

Workpiece Inspection: Check dimensions, shape, surface roughness, etc.

Finishing: Finish, grind, or polish to eliminate defects.

Cleaning and Maintenance: Clean the machine tool and cutting tools, and perform regular maintenance.

Safety Precautions

Personal Protection: Wear protective equipment to avoid chip injuries.

Machine Tool Safety: Ensure safety devices are effective; do not touch moving parts unnecessarily.

Fire Safety: Keep fire-fighting facilities in place to prevent fires.

Advantage of cnc machining brass parts

High Precision and Complex Geometry Machining Capabilities

CNC technology enables micron-level tolerance control, suitable for machining complex shapes (such as precision threads and micro-holes).

Brass has good ductility, making it less prone to cracking during machining, ensuring dimensional stability of the finished product.

Excellent Surface Quality

The machined surface is smooth, allowing direct use in end products (such as decorative parts), reducing the need for subsequent polishing.

Suitable for applications requiring high surface finish (such as electronic connectors and optical components).

High Material Utilization

Brass’s easy-machining properties reduce cutting resistance, tool wear, and material waste.

Suitable for mass production, offering significant cost-effectiveness.

Corrosion Resistance and Long Lifespan

Brass is naturally corrosion-resistant, and machined parts perform stably in humid or chemical environments (such as valves and pipe fittings).

Extended product lifespan and reduced maintenance costs.

Rapid Prototyping and Mass Production Compatibility

CNC programming is flexible, allowing for rapid switching between different designs, suitable for small-batch customization or large-scale production.

Application of cnc machining brass part

Electronics Industry

Applications: Connectors, terminals, switches, circuit board pins.

Automotive Industry

Applications: Sensor housings, fuel system components, gears, decorative parts.

Medical Devices

Applications: Surgical instrument handles, diagnostic equipment parts, pneumatic tubing connectors.

Architecture and Decoration

Applications: Door handles, lighting accessories, artistic sculptures.

Fluid Control and Industrial Equipment

Applications: Valves, pump bodies, pipe fittings, pressure gauge accessories.

FAQ of brass cnc machining

Why choose brass for CNC machining?

Brass is ideal for CNC machining due to: 1. Excellent machinability (especially C360 with lead addition) 2. High dimensional accuracy (tolerances as tight as ±0.01mm) 3. Good corrosion resistance 4. Superior surface finish quality 5. Cost-effectiveness for both prototyping and mass production

What are recommended cutting parameters for brass CNC machining?

Typical parameters vary by alloy and tooling: – Spindle speed: 1000-5000 RPM – Feed rate: 0.1-0.5 mm/rev – Cutting depth: 0.5-3mm – Coolant: Water-soluble cutting fluid recommended to prevent material adhesion

What surface finishes are available after brass CNC machining?

Common finishes include: – Polishing (for high-gloss decorative parts) – Plating (nickel/chrome plating for corrosion protection) – Passivation (to enhance corrosion resistance) – Sandblasting/brushing (for textured surfaces)

What factors affect brass CNC machining costs?

Key cost factors include: 1. Material grade selection 2. Part complexity and machining time 3. Production batch size 4. Required surface finishes 5. Tightness of tolerances

What design considerations are important for brass CNC machining?

Critical design aspects: – Maintain uniform wall thickness (≥1mm recommended) – Include fillets (≥0.5mm radius) for stress relief – Provide adequate clamping surfaces – Avoid deep cavities that hinder chip evacuation – Design clearances for threaded features