CNC machining stainless steel

Overview:

Get competitive price for custom CNC machining stainless steel. Receive comprehensive quotes for other type of aluminum materials and additional surface finishing processes for high-standard prototypes and standard production-run parts.

Tolerance : up to 0.002 inch

MOQ : prototype to small batch(mass production)

Price : 10~500 USD/PCs

Delivery time : 1~7 days

Surface finish : Mechanical Polishing,Brushed / Satin Finish,Sand Blasting / Bead Blasting,Passivation,Electropolishing,PVD,Nickel / Chrome Plating

What is cnc machining stainless steel ?

Stainless steel CNC machining is an automated process that uses pre-programmed computer controls to milling, turning, cutting and drill stainless steel materials with high precision, producing parts or products that meet precise size and shape requirements.

Main Types for stainless steel cnc machining

304 stainless steel

Feature:As the most commonly used austenitic stainless steel, it possesses excellent corrosion resistance, heat resistance, and formability, and is easy to weld and process.

Application:Widely used in food processing, chemical, and medical fields, such as kitchen equipment, chemical containers, and medical device components.

Tensile Strength, Yield (MPa):215

Shear Modulus (GPa) :77

Elongation at Break (%) :70

Hardness (Brinell) :123

Density (g/cm^3) :8

316 Stainless steel

Feature:The addition of molybdenum to 304 stainless steel significantly improves corrosion resistance, particularly against chloride ion corrosion, while maintaining good high-temperature performance.

Application:Suitable for equipment and components in harsh environments such as marine environments, chemical processing, and pharmaceuticals, including seawater treatment equipment, chemical reactors, and medical devices.

Tensile Strength, Yield (MPa):205

Shear Modulus (GPa) :74

Elongation at Break (%) :40

Hardness (Brinell) :187

Density (g/cm^3) :8.03

416 Stainless steel

Feature : Martensitic stainless steel, with added sulfur to improve machinability, also possesses high strength and hardness, as well as good corrosion resistance.

Applications : Suitable for manufacturing mechanical parts requiring high strength and good machinability, such as pump bodies, valves, and automotive transmission components.

Tensile Strength, Yield (MPa):275

Shear Modulus (GPa) :83

Elongation at Break (%) :30

Hardness (Brinell) :156

Density (g/cm^3) :7.8

420 stainless steel

Feature :Martensitic stainless steel, possessing high hardness and wear resistance. Its mechanical properties can be adjusted through heat treatment to meet various requirements.

Application : Suitable for manufacturing cutting tools, molds, surgical instruments, and other components requiring high hardness and wear resistance.

Tensile Strength, Yield (MPa):345

Shear Modulus (GPa) :80.7

Elongation at Break (%) :25

Hardness (Brinell) :198

Density (g/cm^3) :7.8

303 stainless steel

Feature:Sulfur is added to improve machinability and ease of machining, while maintaining basic corrosion resistance.

Applications: Suitable for manufacturing parts that require frequent machining and do not have extremely high corrosion resistance requirements, such as nuts, bolts, shafts, and parts for automated equipment.

Tensile Strength, Yield (MPa):240

Shear Modulus (GPa) :77.2

Elongation at Break (%) :50

Hardness (Brinell) :160

Density (g/cm^3) :8

2205 Duplex Stainless Steel

Feature : Combining the advantages of austenitic and ferritic stainless steels, it possesses excellent corrosion resistance, high strength, and good weldability, while also being cost-effective.

Applications : Suitable for equipment and components in high-stress, high-corrosion environments in industries such as oil, gas, and chemicals, such as pipes, valves, and pump bodies.

Tensile Strength, Yield (MPa):620~900

Shear Modulus (GPa) :220

Elongation at Break (%) :27

Hardness (Brinell) :300

Density (g/cm^3) :7.8

410 stainless steel

Feature :Chromium-containing martensitic stainless steel possesses high hardness and strength, good wear resistance, and some corrosion resistance. It is heat-treatable, magnetic, and has a low nickel content.

Application : It is widely used in the manufacture of knives and tableware, machine parts processing, some medical device production, and the production of atmospheric corrosion-resistant components in the petrochemical industry. (Bearings, gears, pump shafts, valve components, scalpels, pipes, fasteners)

Tensile Strength, Yield (MPa):310

Shear Modulus (GPa) :73

Elongation at Break (%) :25

Hardness (Brinell) :148

Density (g/cm^3) :7.8

Surface finish for CNC machining parts

After CNC machining of stainless steel, surface finish is crucial for improving the performance and appearance of the parts. It not only improves surface quality and enhances corrosion and wear resistance but also adds to their aesthetic appeal. The following introduces several practical surface finish methods for stainless steel CNC parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity.

Guideline of cnc machining stainless steel :

Material Inspection : Stainless steel composition is analyzed using a spectrometer. For 304 series stainless steel, ensure Cr ≥ 16% and Ni ≥ 8%, and generate a material report.

Process Planning : Process is broken down according to the 3D model (STEP/IGS), prioritizing high-speed machining (HSC), with a cutting speed of 100-300 m/min.

Tool Selection : Carbide TiAlN coated tools, feed rate 0.1-0.3 mm/r, depth of cut 0.5-2 mm. PCD tools are used for difficult-to-machine materials such as 316L.

Key Control Points : After rough machining, low-temperature aging at 200℃ for 2 hours to relieve internal stress and prevent deformation.

Cutting Parameters : Milling of 304 stainless steel, VC = 150 m/min, f = 0.15 mm/z, ap = 1.5 mm, oil mist lubrication and cooling.

First Article Inspection : The first article of each batch is inspected dimensionally using a CMM, and a PPAP document is generated.

Inspection frequency : 3 pieces are randomly selected from every 50 pieces produced in batches, and critical dimensions are monitored online using a laser diameter gauge.

Record requirements : Complete machining parameter records (cutting speed, feed rate, tool life) must be maintained for at least 3 years.

Capability of cnc machining stainless steel :

Maximum dimensions : 1500mm×800mm×600mm

Minimum machining dimensions : 5mm×5mm×0.5mm

Maximum machining length : 3000mm

Diameter range : φ3mm-φ500mm

Positioning accuracy : X/Y/Z axis positioning accuracy up to ±0.005mm, repeatability ±0.003mm

Linear dimensional tolerance : Up to IT5 grade (±0.013mm/300mm)

Angle tolerance : ±5″

Surface quality : Mirror finish Ra≤0.2μm, precision grinding Ra≤0.4μm, conventional milling Ra≤1.6μm

Geometric tolerances : Flatness ≤0.01mm/1000mm, Cylindricity ≤0.005mm, Perpendicularity ≤0.008mm/300mm

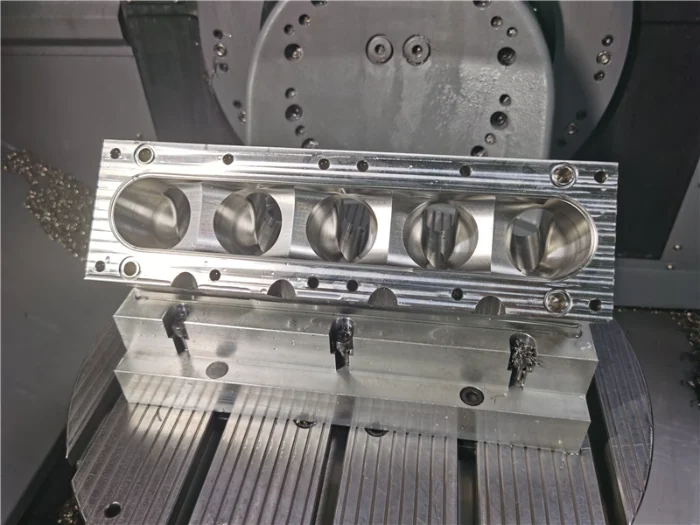

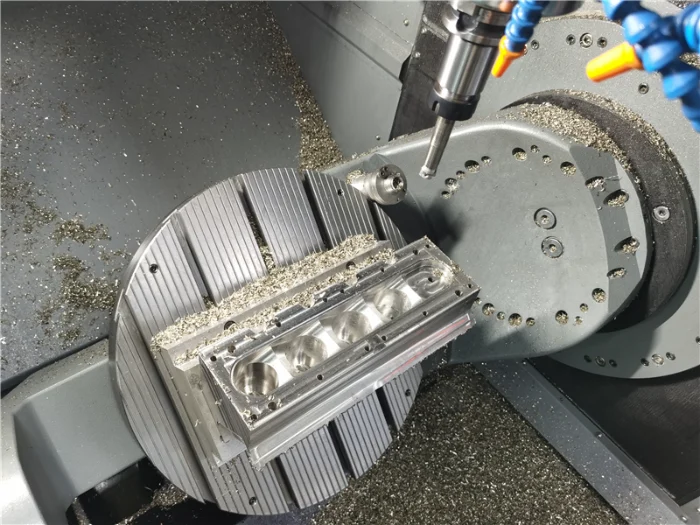

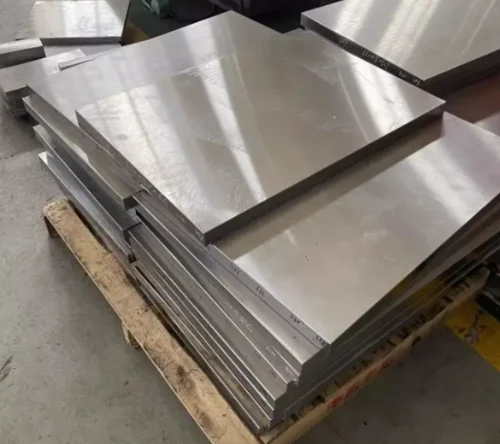

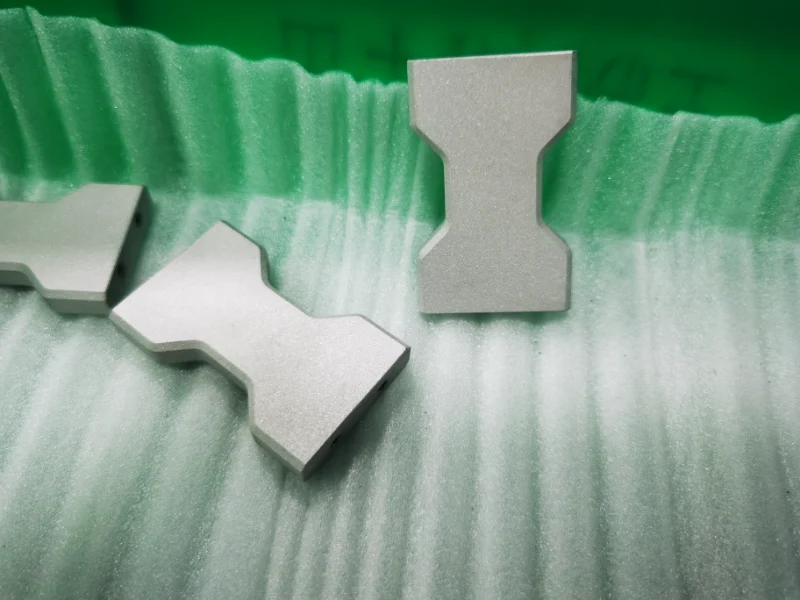

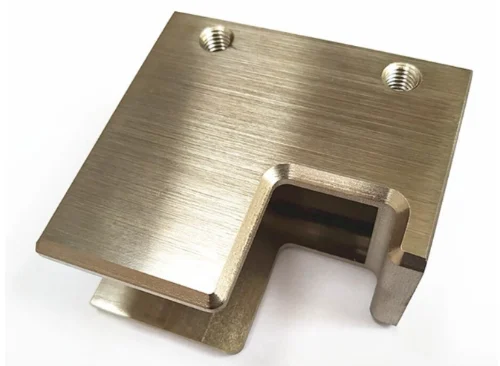

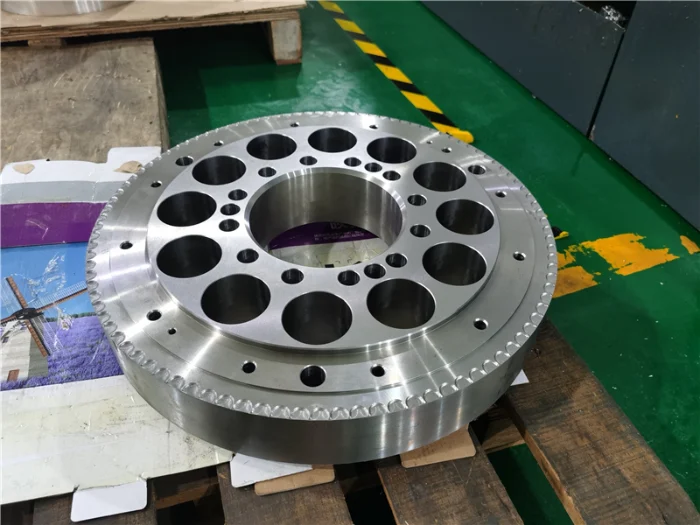

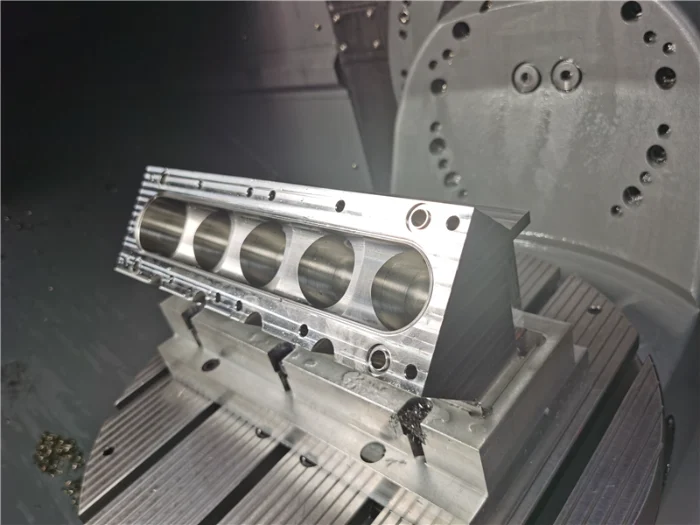

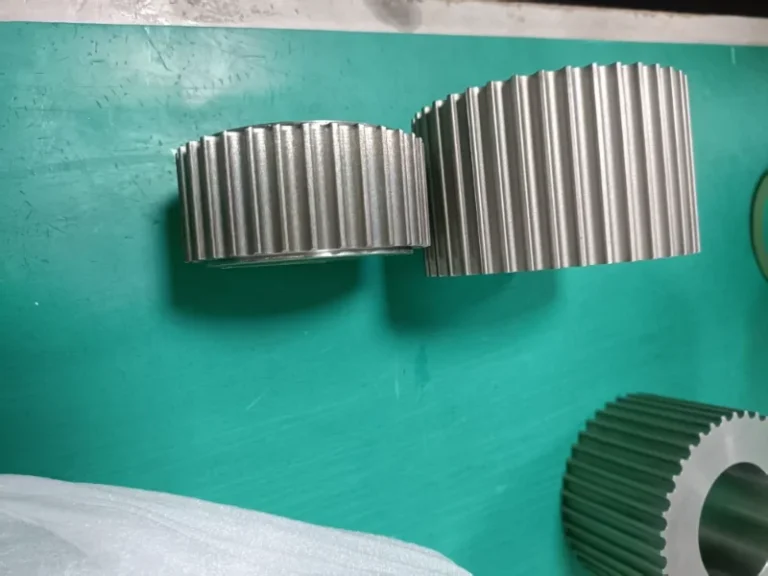

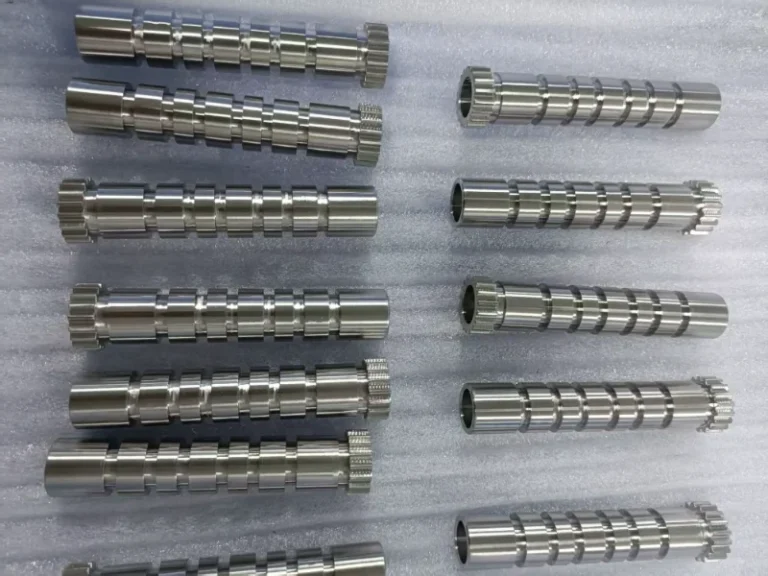

Cnc machining stainless steel cases

Advantage of cnc machining stainless steel

High-Precision Machining : Program control achieves micron-level precision (within ±0.01mm), meeting stringent tolerance requirements in aerospace, medical, and other industries.

One-Step Forming of Complex Structures : Multi-axis linkage (e.g., five-axis) machining of deep cavities and irregular curved surfaces reduces assembly errors and improves overall part performance.

Optimized Material Utilization : Precision nesting combined with high-speed cutting reduces waste of precious stainless steels such as 316L, controlling unit cost.

Controllable Surface Quality : High-speed cutting combined with precision tools directly achieves a surface finish of Ra 0.8 or lower, reducing subsequent polishing processes.

Automated and Efficient Production : 24-hour continuous operation, with batch production efficiency 3-5 times higher than ordinary machine tools, suitable for large-volume orders.

High Process Flexibility : Parts can be switched for machining simply by modifying the program, without changing molds, shortening pre-production preparation time.

Application of cnc machining stainless steel

Aerospace: Machining engine turbine blades, structural components, and hydraulic system parts, utilizing high-temperature resistance (e.g., 310S withstands 1900°F) and corrosion resistance.

Medical Devices: Manufacturing surgical implants (knee, hip joints), biopsy tubes, and blade holders, meeting sterility and biocompatibility standards.

Automotive Industry: Producing high-precision transmission components (shafts, gears), fuel system parts, and decorative parts, balancing wear resistance and aesthetics.

Food Processing Equipment: Machining valves, pump bodies, and pipe fittings, meeting the corrosion resistance and easy-to-clean requirements of 304/304L stainless steel.

Marine Engineering: Manufacturing ship components and offshore platform equipment, relying on the seawater corrosion resistance of 316L duplex stainless steel.

Chemical and Petroleum Industries: Producing pumps, valves, pipe fittings, and reactor components, adaptable to harsh operating conditions involving strong acids, strong alkalis, and high temperatures and pressures.

FAQ of cnc machining stainless steel

How to prevent rapid tool wear during stainless steel CNC machining?

Use carbide tools (such as YG6, YG8) or coated tools (TiAlN coating) to improve wear resistance.

Reduce cutting speed (100-200 m/min recommended) to reduce heat buildup.

Use coolant for adequate lubrication and cooling to avoid dry cutting.

How to solve the built-up edge problem during stainless steel machining?

Use sharp tools with a rake angle of 10°–20° and a clearance angle of 5°–8° to reduce cutting resistance.

Increase feed rate (0.15-0.3 mm/r) to promote chip breaking.

Use climb milling to reduce friction between chips and the tool.

How to control part deformation after stainless steel machining?

Perform low-temperature aging treatment (e.g., 200℃ × 2h) after rough machining to eliminate internal stress.

Control the depth of cut (0.5-2 mm) to avoid excessive single-cutting depth.

Employ symmetrical machining or multiple flipping processes to balance stress distribution.

What if the surface roughness of stainless steel CNC machined does not meet standards?

Replace tools regularly to ensure a sharp cutting edge (surface roughness ≤ Ra0.4).

Optimize cutting parameters: VC = 150 m/min, f = 0.15 mm/z, ap = 1.5 mm.

Use oil mist lubrication or high-pressure coolant to improve chip removal.

What are the main differences between CNC machining of stainless steel and ordinary steel?

Material properties: Stainless steel has higher hardness (HRC≥25) and greater toughness, but poorer thermal conductivity (only 1/3 that of carbon steel).

Machining challenges: Prone to work hardening (hardness increase of 30%-50% in the cutting area), rapid tool wear, and easy surface scratching.

Process requirements: Requires lower cutting speeds, more sufficient cooling, more precise tools, and control of thermal deformation.