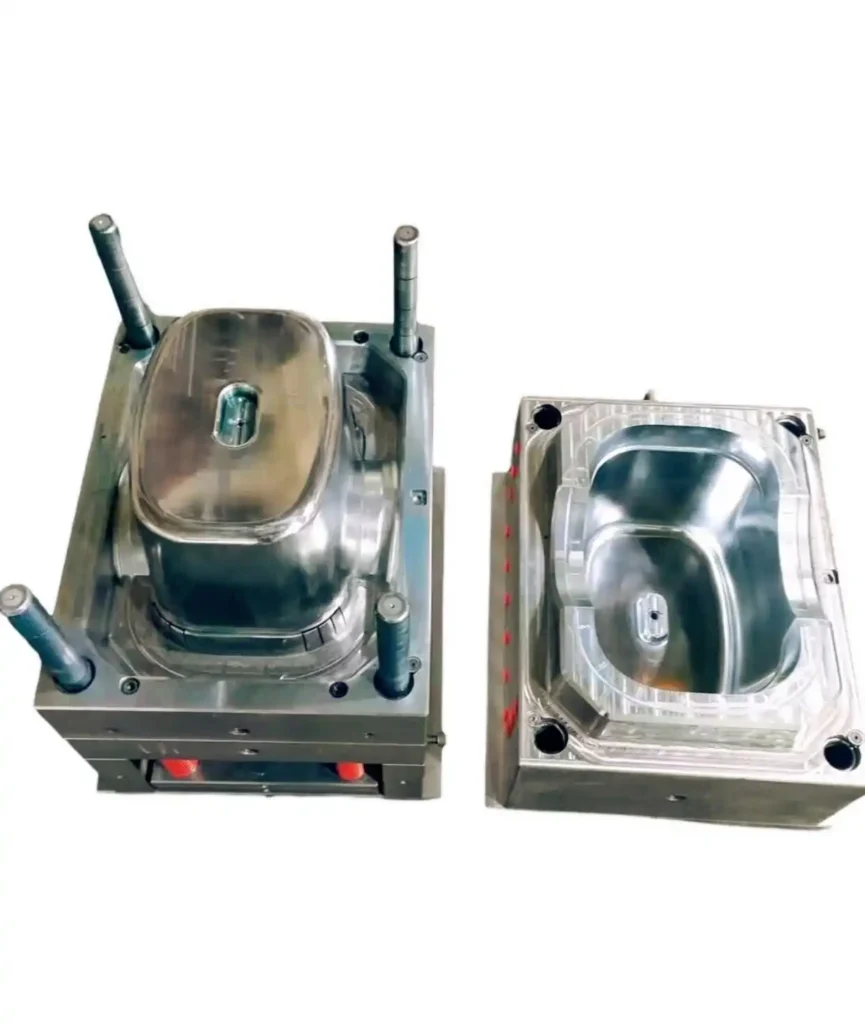

Molding service

Overview:

Whether it’s precision injection molding service, die-casting, or silicone molding, we offer one-stop solutions from prototyping to mass production. Leveraging 20 years of industry experience and imported German equipment, we excel at processing highly complex structural parts (such as thin-walled, multi-cavity, and special-shaped curved surfaces). We support customization in over 50 materials, including PP, PC, and ABS, with tolerances as tight as ±0.01mm and a consistent yield rate exceeding 99%.

What is molding service ?

Molding Service is a process service that processes materials (such as plastics, metals, rubber, etc.) into specific shapes through molds. Depending on the material and application scenario, common molding service types include: injection molding, die casting, hot pressing, blow molding, rotational molding.

Material for mold

In mold services, the choice of materials directly affects the mold life, processing accuracy and manufacturing cost. The following is a brief description of commonly used materials and their characteristics:

Tool steel mold

Characteristics: High hardness, wear resistance, and thermal fatigue resistance, suitable for long-term, high-load use.

Sub-categories:

Cold work tool steels (such as D2 and O1): Used in stamping and shearing dies, with a hardness of HRC 58-62.

Hot work tool steels (such as H13 and H21): Used in die-casting and forging dies, offering high-temperature resistance (600-800°C) and resistance to thermal cracking.

Plastic mold steels (such as P20 and 718): Used in injection molds, offering excellent polishability and suiting the production of transparent parts.

Applications: Automotive parts die-casting, electronic connector stamping, and appliance housing injection molding.

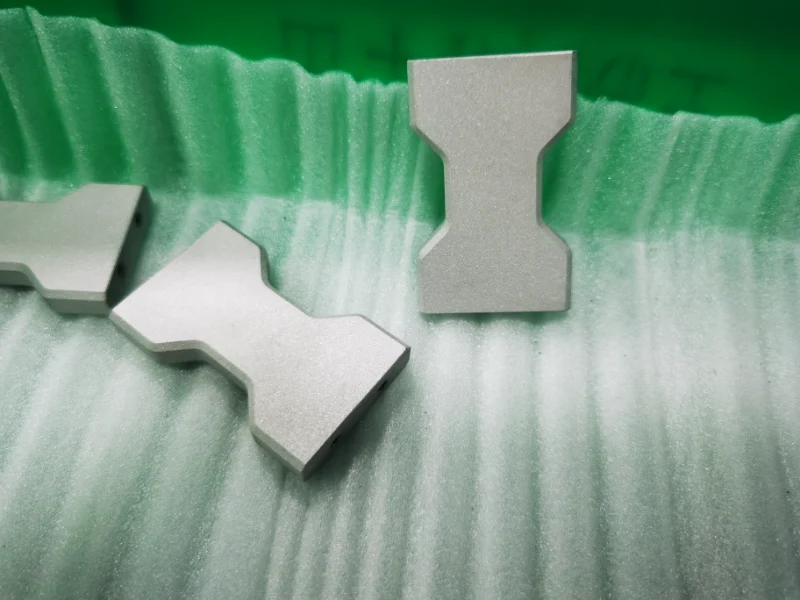

Powder Metallurgy Steel mold

Properties: Produced through a powder metallurgy process, it boasts uniform microstructure and strong impact resistance.

Representative materials: ASP23 and V10 (ultra-fine grain steel), with a hardness of HRC 63-65.

Applications: High-precision gear stamping and die-casting molds for complex structures.

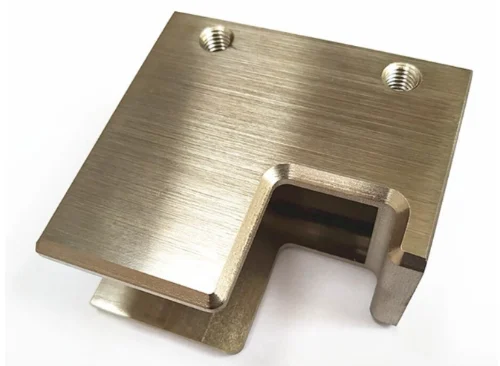

Stainless Steel mold

Properties: Corrosion resistance, excellent polishing properties, suitable for food-grade and medical molds.

Common grades:

420: Martensitic stainless steel, hardness 48-52 HRC, used for tableware and medical device molds.

316L: Austenitic stainless steel, acid and alkali resistant, used for pharmaceutical packaging molds.

Applications: Injection molds for syringes, surgical instruments, and food containers.

Powder Metallurgy Steel mold

Properties: Produced through a powder metallurgy process, it boasts uniform microstructure and strong impact resistance.

Representative materials: ASP23 and V10 (ultra-fine grain steel), with a hardness of HRC 63-65.

Applications: High-precision gear stamping and die-casting molds for complex structures.

Aluminum Alloy mold

Properties: Low density (1/3 that of steel), good thermal conductivity, fast processing speed, suitable for rapid mold trials.

Common grades:

6061-T6: General-purpose aluminum alloy with a hardness of HB 95, suitable for low-volume molds.

7075-T6: High-strength aluminum alloy with a hardness of HB 150, suitable for molds with complex structures.

Applications: Prototype development and small-batch customization (such as 3C product housings).

Copper Alloy mold

Properties: Excellent thermal conductivity (three times that of steel), suitable for molds requiring rapid cooling.

Representative material: Beryllium copper (C17200), with a hardness of 38-42 HRC, used for electrodes and die-casting mold inserts.

Applications: Die-casting of mobile phone midframes and molding of precision electronic components.

Surface finish for molding parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various molding parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

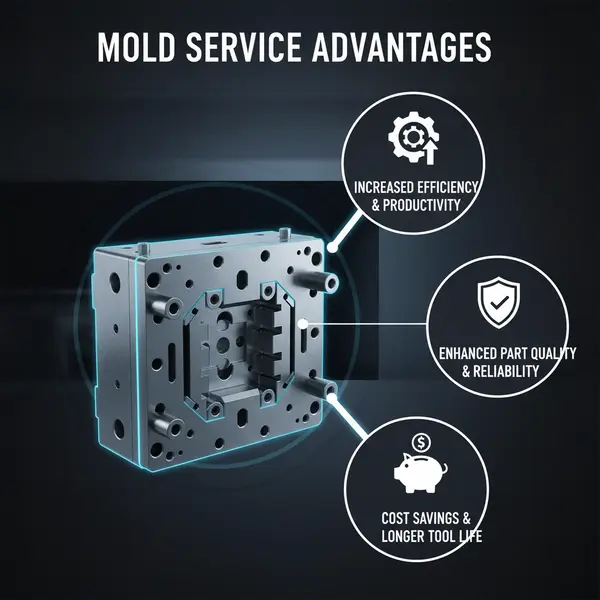

Advantage of molding service

1. High Precision and Consistency

Advantages: Molds are manufactured using processes such as CNC machining and electro-discharge machining (EDM), with dimensional tolerances controlled within ±0.001mm, ensuring perfect consistency for every product.

2. High Efficiency in Mass Production

Advantages: Molds can produce tens of thousands to millions of products in a single pass, with unit costs significantly decreasing as production increases.

3. Optimized Material Utilization

Advantages: Moldflow analysis optimizes gate location and runner design, reducing scrap.

4. Complex Structure Capability

Advantages: Molds can produce complex structures difficult to achieve using traditional machining (such as thin walls, multiple cavities, and special-shaped curved surfaces).

5. Controllable Surface Quality

Advantages: Mold surfaces can be treated with chrome plating, nitriding, and PVD coating to enhance surface hardness, corrosion resistance, or gloss.

6. Rapid Prototyping

Advantages: Aluminum alloy or resin molds can be quickly manufactured, shortening product development cycles.

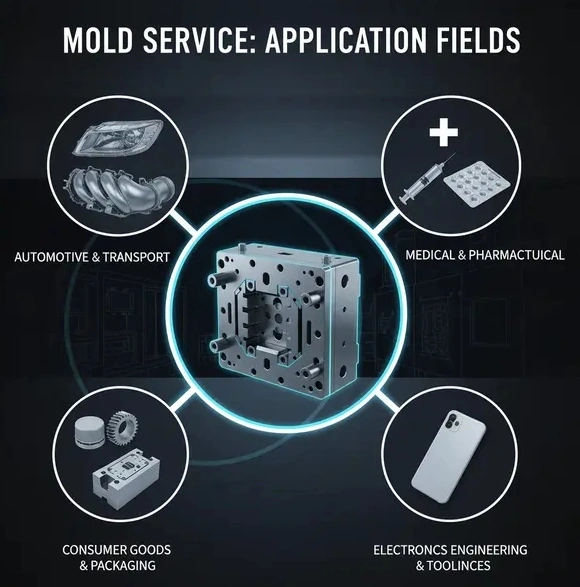

Application of molding service

1. Automotive Industry

Body parts: bumpers, instrument panels, door trim panels (injection molds).

Powertrain: engine blocks, transmission housings (die-cast molds).

Lightweighting: aluminum alloy wheels, battery trays (low-pressure die casting molds).

Advantages: Mold lifespan reaches 500,000-1,000,000 cycles, meeting the high reliability requirements of the automotive industry.

2. Electronics and Consumer Electronics Products

Casings: mobile phone midframes, laptop cases (CNC machining + injection molds).

Connectors: USB ports, HDMI connectors (precision stamping molds).

Internal components: heat sinks, shielding covers (die-casting + CNC composite molds).

Trend: 5G communication equipment requires mold accuracy of up to ±0.005mm.

3. Medical Field

Implants: artificial joints, dental implants (titanium alloy precision casting molds).

Instruments: surgical scalpel handles, syringes (medical-grade stainless steel molds). Packaging: Vaccine vials, prefilled syringes (cleanroom injection mold).

Standards: Must comply with the ISO 13485 medical quality management system, and the mold material must be biocompatible certified.

4. Home Appliances and Daily Necessities

Large Appliances: Washing machine drums, air conditioner housings (roto-molding + injection mold).

Small Appliances: Electric kettles, hair dryers (two-shot injection mold).

Daily Necessities: Plastic tableware, storage boxes (gas-assisted injection mold).

Innovation: Spray-free molds reduce post-processing steps and reduce costs by 30%.

FAQ of molding service

Q1: What are the main types of Molding Service processes?

A: Key processes include Injection Molding (plastic parts), Die Casting (metal components), Blow Molding (hollow products), Extrusion (long profiles), and Thermoforming (thin-wall items). Choose based on material, precision, and volume needs.

Q2: What factors determine Molding Service costs?

A: Costs depend on mold complexity/material (30-60% of total), material type (plastic/metal prices), production volume (larger batches reduce per-unit costs), and post-processing (e.g., painting, assembly).

Q3: How to select a Molding Service supplier?

A: Prioritize suppliers with technical expertise (complex structures/precision tolerance), certified equipment (CNC/EDM/automated machines), industry experience (automotive/medical cases), and responsive support (design to post-sale). Avoid low-cost suppliers with short mold lifespans.

Q4: What is the typical production cycle?

A: Cycles vary: Design review (1-3 days), mold making (7-15 days for aluminum/30-60 days for steel), trial molding (3-7 days), and mass production (days to weeks). Use simulation tools or local suppliers to speed up.

Q5: How to fix common molded product defects?

A: Solutions: Sink marks (optimize gate/packing), flash (trim mold/reduce pressure), flow marks (adjust melt temp/design), warpage (modify cooling/packing). Use DOE for optimal parameters.

Q6: Does Molding Service support eco-friendly materials?

A: Yes, options include biobased plastics (PLA), recycled materials (PCR/PIR), halogen-free compounds, and lightweight designs (thin-wall/foam). Balance performance with sustainability.

Q7: Can Molding Service achieve multi-material integration?

A: Yes, via two-shot molding (soft/hard plastics), insert molding (metal parts), MuCell foam (lightweighting), and 3D-printed molds (conformal cooling). Reduces assembly and boosts strength.