Injection Molding:

Looking for professional, efficient injection molding solutions and precise quotes? Contact us today to customize your dedicated production plan!

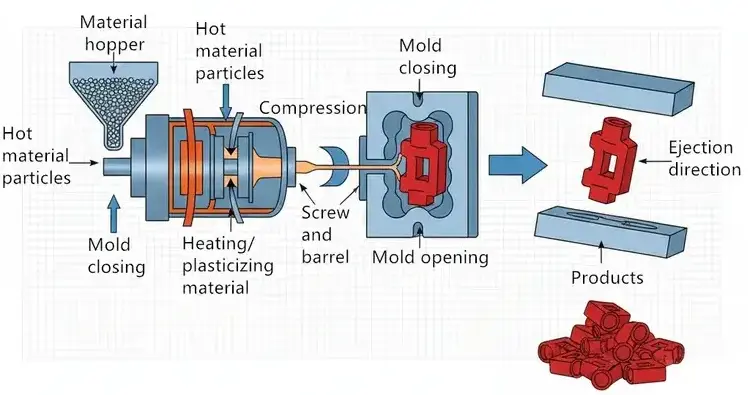

What is injection molding ?

Injection molding is a manufacturing process that forms products into specific shapes by injecting molten materials (plastics, metals, or composites) into a mold cavity under high pressure, followed by cooling and solidification. This technology is widely used for producing high-volume, high-precision, and complex-shaped parts, characterized by high automation levels, high material utilization (up to 95%), and excellent product consistency.

Material for injection molding machining

Injection molding machining is widely applicable for processing various plastics and certain metal materials, enabling the efficient and precise production of complex-shaped, high-quality components. Below are the materials we commonly use for injection molding:

Metal material :

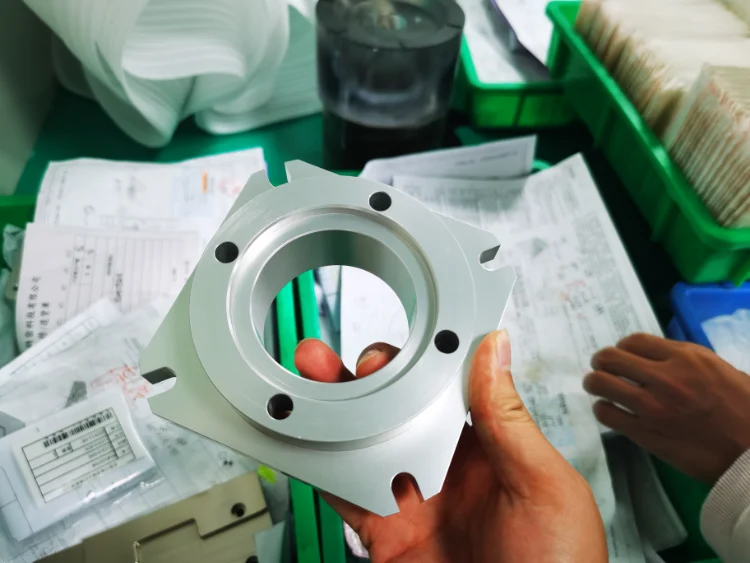

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Plastic material :

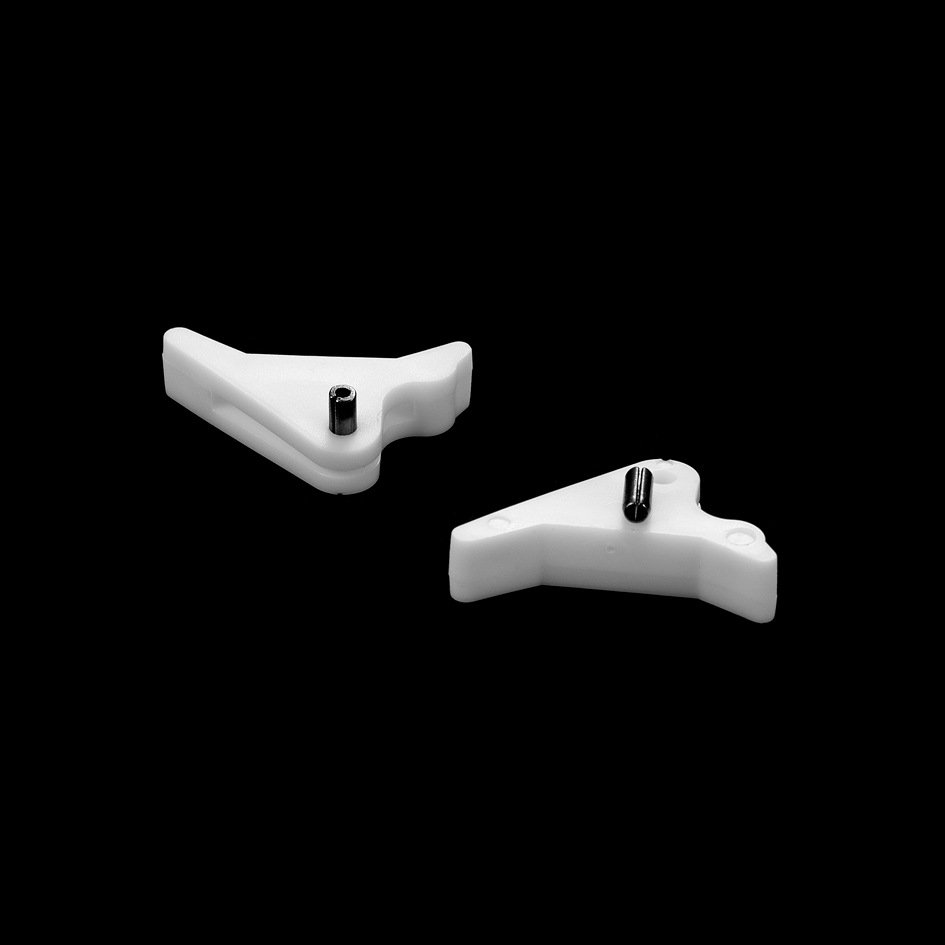

ABS

Combining the rigidity of acrylonitrile, the toughness of butadiene, and the processability of styrene, it offers excellent impact resistance (maintaining toughness even at low temperatures) with a balanced hardness and rigidity. Suitable for precision components subjected to moderate loads, it is ideal for manufacturing precision parts such as electronic and electrical enclosures, automotive ducting, interior trim components, and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

Injection molding capability

| Item | Specification |

|---|---|

| Positioning Accuracy | ±0.01mm |

| Repeated Positioning Accuracy | ≤0.005mm |

| Maximum Injection Amount | 50-5000g |

| Maximum Mold Stroke | 500-1200mm |

| Mold Size | 400-1800mm |

| Dimensional Tolerance Control | ±0.05mm (General Parts), ±0.01mm (Precision Parts) |

| Minimum Wall Thickness For Forming | 0.3mm (PC Material), 0.5mm (ABS Material) |

| Surface Quality | Mirror Polishing Up To Ra0.02μm, Texture Processing Resolution 50μm |

Injection molding guide

| DEFECT TYPE | OCCURRENCE RATE | ROOT CAUSE | IMPROVEMENT MEASURES | EFFECT |

|---|---|---|---|---|

| Warpage and Deformation | 3.20% | Uneven Cooling | Optimize cooling water path, increase pressure by 15% | Reduce to 0.8% |

| Shrinkage Marks | 2.50% | Insufficient Holding Pressure | Extend holding pressure time, increase melt temperature by 5°C | Reduce to 0.5% |

| Flash | 1.80% | Insufficient Locking Force | Calculate minimum locking force based on projected product area | Reduce to 0.3% |

Advantage of injection molding

Production Efficiency:

Single-cavity production cycles can be as short as 10 seconds (e.g., bottle caps), while multi-cavity molds enable single-shot molding of 100+ parts, suitable for large-scale production with annual output reaching millions.

Design Flexibility:

Capable of molding complex structures (e.g., hollow sections, thin walls, embedded inserts), with minimum wall thickness down to 0.2mm (micro-injection technology), meeting precision requirements for electronic components.

Material Versatility:

Supports multi-material molding including plastics, metals, and ceramics. Co-injection enables composite parts combining soft and hard materials (e.g., rubber grips + plastic housings).

Cost Advantage:

Delivers 80% lower unit costs than 3D printing for mass production. Metal injection molding (MIM) reduces assembly processes, cutting total costs by over 30%.

Application of injection molding parts

Automotive Industry

Key Components: Dashboard Frame (PC/ABS Alloy), Battery Housing (PA6 + Glass Fiber Reinforced), Lightweight Structural Parts (Magnesium Alloy MIM)

Medical Devices

Representative Products: Insulin Pen Shell (PC), Surgical Instrument Pliers Head (17-4PH Stainless Steel MIM)

Consumer Electronics

Representative Products: Smartphone Mid-Frame (Aluminum Alloy Die-Casting + Injection Molding), VR Headset Housing (PC/PMMA Composite)

Aerospace

Application Examples: Satellite Bracket (Titanium Alloy MIM), Cabin Interior Components (PEEK Injection Molding)

FAQ of injection molding

What is the cost range for injection molds?

Mold costs depend on complexity and materials. Simple plastic molds range from approximately $1,000 to $20,000, while high-precision multi-cavity molds can reach $100,000 to $500,000. Metal injection molding (MIM) molds typically incur an additional 30% to 50% cost due to higher precision requirements.

What is the minimum economically viable production batch size?

Plastic injection molding is suitable for annual production runs ≥10,000 units, while metal MIM is suitable for ≥50,000 units. For small batch production (<1,000 units), 3D printing or silicone mold casting is recommended.

How to address warping and deformation in injection-molded parts?

Control through three measures:

① Optimize mold cooling system (temperature difference ≤5℃)

② Implement holding pressure compensation (holding pressure at 80% of injection pressure)

③ Select low-shrinkage materials (e.g., PA66 with 20% glass fiber reinforcement, shrinkage controllable at 0.3%)

What distinguishes metal injection molding (MIM) from traditional forging?

MIM suits complex-shaped small parts (weight <100g) with 95% material utilization; forging suits large structural components (e.g., automotive crankshafts) but incurs up to 40% material waste. MIM parts exhibit mechanical properties close to forgings (tensile strength difference <5%).