Aluminum Extrusion:

What is aluminum extrusion ?

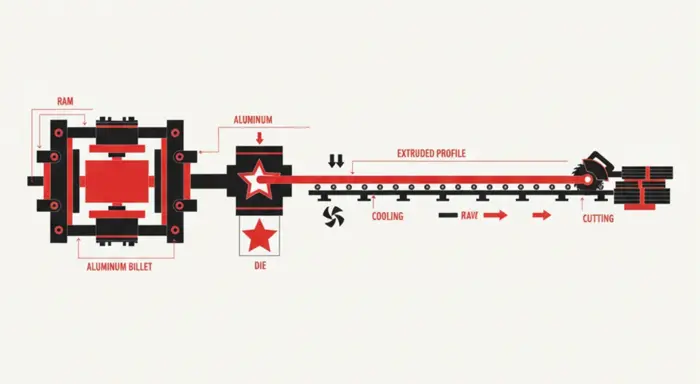

Aluminum extrusion is a manufacturing process that shapes heated aluminum alloy billets (400-500°C) into continuous cross-section profiles by forcing them through a die under high pressure. Based on die movement, it is categorized into direct extrusion (billets move while dies remain stationary) and indirect extrusion (dies move while billets remain stationary). The latter reduces friction and enhances surface quality.

Aluminum extrusion machinable materials

Common Aluminum Alloy Grades and Properties

| SERIES | TYPICAL MODEL NUMBER | MAIN ALLOY ELEMENTS | CORE CHARACTERISTICS | APPLICATION SCENARIOS |

|---|---|---|---|---|

| 6xxx | 6061-T6 | Mg, Si | Tensile strength 310MPa, resistant to anodic oxidation | Automotive structural components, bicycle frames |

| 6xxx | 6063-T5 | Mg, Si | Elongation rate 12%, excellent rationality on surface treatment | Architectural doors and windows, radiators |

| 5xxx | 5052-H32 | Mg (2.5%) | Corrosion-resistant to seawater, density 2.68g/cm³ | Ship decks, fuel tanks |

| 7xxx | 7075-T651 | Zn, Mg, Cu | Hardness 150HB, strength exceeds some steel materials | Aero-engine blades, racing car suspensions |

Surface finishes for aluminum extrusion profile

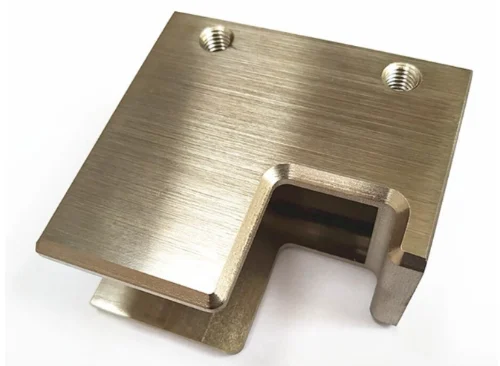

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Aluminum extrusion capability:

| ITEM | SPECIFICATION |

|---|---|

| BILLET SPECIFICATIONS | Diameter 100-500 mm, Length 1-7 m |

| MAXIMUM EXTRUSION CROSS-SECTION | Width 1100 mm |

| MINIMUM WALL THICKNESS | 0.8 mm |

| PRECISION CONTROL | ±0.05 mm (for length 5 m),Coarse grain ring depth ≤ 0.3 mm,Straightness ≤ 0.3 mm/m |

Aluminum extrusion guideline:

| ITEM | SPECIFICATION |

|---|---|

| HEATING TEMPERATURE | 6063 Alloy: 480±20°C; 7075 Alloy: 450±10°C |

| EXTRUSION SPEED | 20-50 m/min (simple cross-section); 5-15 m/min (complex cross-section) |

| MOLD PREHEATING | 450-500°C (mold steel H13) |

| DIMENSIONAL TOLERANCE | Precision grade ±0.1 mm/m |

| SURFACE TREATMENT | Anodized film thickness ≥ 10μm (architectural material); Salt spray test ≥ 1000 hours |

| MECHANICAL PROPERTIES | 6061-T6 Yield strength ≥ 276MPa, Elongation ≥ 10% |

Advantage of aluminum extrusion:

Material utilization rate: Nearly 95% (traditional machining achieves only 60%)

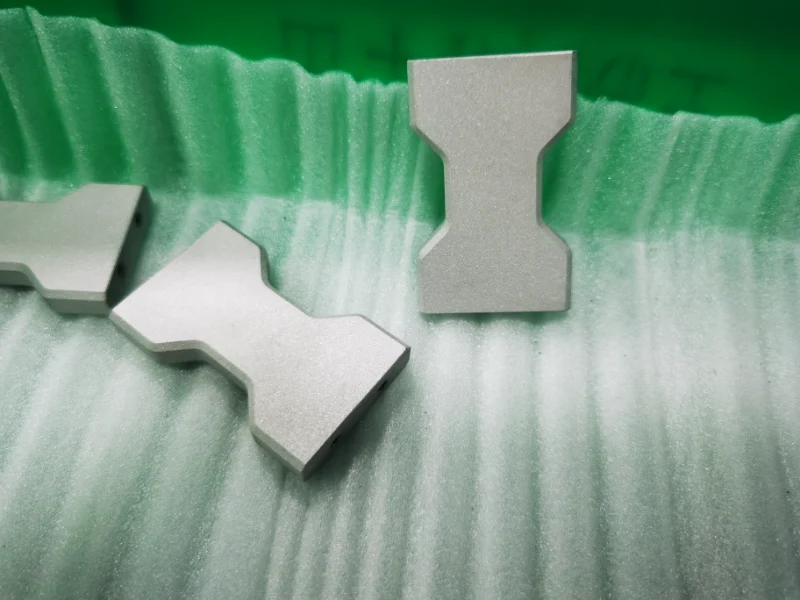

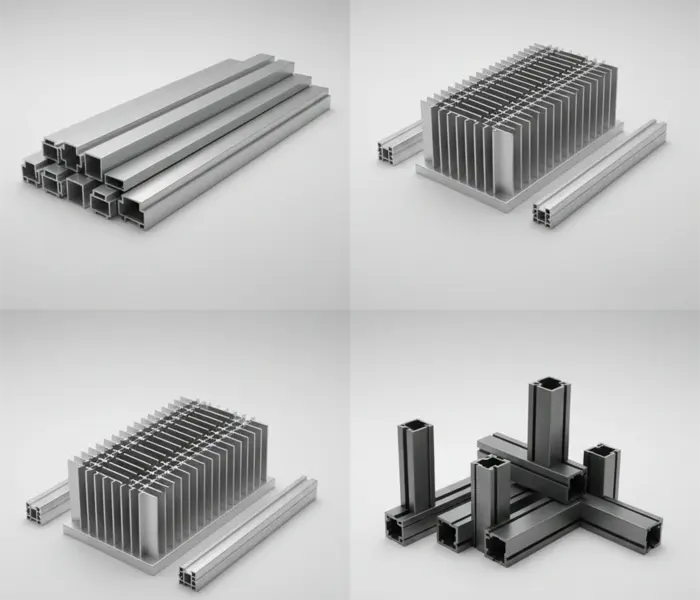

Design flexibility: Capable of forming complex cross-sections (e.g., multi-hole heat dissipation profiles)

Cost advantage: Unit cost during mass production is 30% lower than die-casting processes

Weight reduction: 40-60% lighter than steel structures

Sustainability: 100% recyclable; recycled aluminum requires only 5% of the energy needed for primary aluminum production

Application of aluminum extrusion:

Construction Industry:

Used in doors, windows, curtain walls, and more to enhance architectural aesthetics and durability while reducing structural load.

Transportation:

Manufacturing lightweight components for automobiles and trains to improve fuel efficiency and operational performance.

Electronics and Appliances:

Serving as heat sinks and housing materials to ensure stable device operation and extend service life.

Machinery and Equipment:

Employed in frames, guide rails, and similar applications to provide high-strength support and guarantee precise equipment movement.

Home Furnishings:

Furniture frames and decorative elements enable flexible design, enhancing both style and durability in home interiors.

Renewable Energy:

Solar panels and wind turbine supports feature corrosion resistance and lightweight construction, supporting clean energy initiatives.

FAQ of aluminum extrusion

How to Address Surface Bubbling in Aluminum Extrusions?

① Homogenize billet treatment (560°C/6 hours); ② Mold vent groove depth 0.03-0.05mm; ③ Reduce extrusion speed by 15%

How to Select Between 6061 and 6063 Alloys?

Select 6061 for structural load-bearing (high strength); choose 6063 for decorative components (superior surface finish).

What Factors Limit Maximum Extrusion Length?

① Extruder bed length (typically ≤50m); ② Profile rigidity (length-to-diameter ratio >200 prone to instability).

How to control deformation in thin-walled profiles?

Employ “progressive cooling” (rapid cooling in initial section, gradual cooling in final section), maintaining elongation within 0.8-1.2%

Cost break-even point between aluminum extrusion and 3D printing?

For batches <500 units, choose 3D printing; for >1000 units, aluminum extrusion is more economical (lower mold cost allocation).