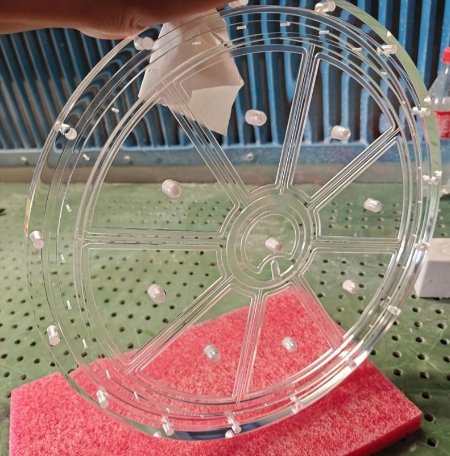

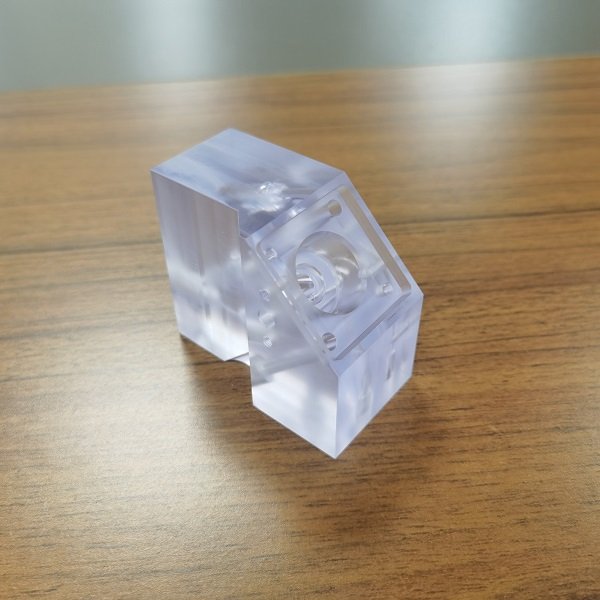

CNC machining acrylic

Acrylic CNC Machining refers to the process of using computer numerical control (CNC) equipment to perform precise path milling, cutting, turning, and other operations on acrylic (chemical name: polymethyl methacrylate, PMMA) material through pre-programmed digital sequences. This enables the automated, high-precision manufacturing of acrylic components or finished products.

Acrylic in cnc machining

Price : 10-50 USD / pcs

Lead time : 1-5 days

Wall thickness : 1 mm

Tolerance : 0.2 mm

Max part size : 2000 mm*1000 mm*1000 mm

Available acrylic in Weldo :Transparent, translucent, colored, preset textures Acrylic, sheets, rods, tubes

Acrylic material Features

Acrylic is a thermoplastic with a light transmittance of 92%-95%, close to that of glass, and a density that is lighter than glass. It is harder than ordinary plastics but weaker than metal and is relatively easy to scratch. It has a certain degree of tensile strength, but its overall toughness is not as good as some engineering plastics. It is a brittle material and has good weather resistance and chemical corrosion resistance, but it will be dissolved or corroded by some organic solvents (such as acetone and chloroform). It is mainly used for precision processing into display screen protective covers, instrument housings, medical device housings, etc.

| Density | Tensile strength | Fatigue strength | Hardness | Longation at break |

|---|---|---|---|---|

| 1.17-1.20 g/cm3 | 50-75 MPa | 15-25 MPa | 80-100 HRM | 2-5% |

Surface finishes option for acrylic part

| Polishing | Flame polishing, wheel polishing, diamond polishing, eliminate fine scratches and unevenness, and improve glossiness |

|---|---|

| Coating | Hardening/anti-glare/anti-fingerprint coating, forming a functional coating on the acrylic surface through vacuum coating or coating |

| Printing | Screen/UV printing, leaving patterns or text on the acrylic surface |

| Sandblasting | High-pressure air sprays sand particles (such as carborundum, glass sand, etc.) onto the acrylic surface to make the surface rough and form a frosted effect |

| Texture | Engraving texture/embossing treatment: CNC engraving machine or laser engraving machine engraves preset texture patterns / presses through a mold with specific texture to form various texture effects on the surface |

Pro and cons of cnc machining acrylic

| Advantages |

|

| Disadvantages |

|

Application of cnc machining acrylic part

Advertising & Display Industry

Production of light boxes, display stands, signboards, direction signs, and exhibition props.

Acrylic has excellent light transmission and smooth edges after cutting, making it ideal for brand displays.

Electronics & Optical Products

Transparent housings, screen panels, and protective covers.

Optical-grade acrylic can be used for lenses, light guides, and lampshades.

Medical Equipment

Transparent panels, test boxes, fluid channels, and housing parts for medical devices.

Acrylic is non-toxic and resistant to chemical corrosion, often used in medical and laboratory equipment.

Automotive & Transportation

Instrument panels, lampshades, and interior decorative parts.

CNC machining ensures high precision and smooth surfaces.

Architecture & Interior Decoration

Acrylic partitions, decorative panels, and artistic carvings.

With strong light transmission and customizability, acrylic is often used as a safer alternative to glass.

Consumer Goods & Gifts

Trophies, customized crafts, phone holders, and cosmetic display boxes.

CNC machining enables complex shapes and smooth edges.

Prototyping & Industrial Components

Prototypes and small-batch functional parts.

Suitable for industrial parts requiring transparency or insulation.

Cnc machining acrylic FAQ

1. What is acrylic CNC machining?

Acrylic CNC machining is a precision manufacturing process that uses computer-controlled machines to cut, mill, or engrave acrylic sheets and blocks into customized shapes and components.

2. What are the advantages of CNC machining acrylic?

The main benefits include high precision (0.01–0.1 mm), smooth edges, strong design flexibility, and the ability to produce both prototypes and mass production parts with consistent quality.

3. What applications use acrylic CNC machining?

It is widely applied in advertising displays, signage, electronics, optical components, medical devices, architectural decoration, consumer goods, and industrial prototypes.

4. Can CNC machining make acrylic parts transparent and polished?

Yes. With proper CNC machining combined with post-processing techniques such as flame polishing or buffing, acrylic parts can achieve glass-like transparency and a flawless finish.

5. What thickness of acrylic can be CNC machined?

CNC machining can handle a broad range of acrylic thicknesses, typically from 1 mm to over 100 mm, depending on the machine’s capabilities and project requirements.