Medical industry

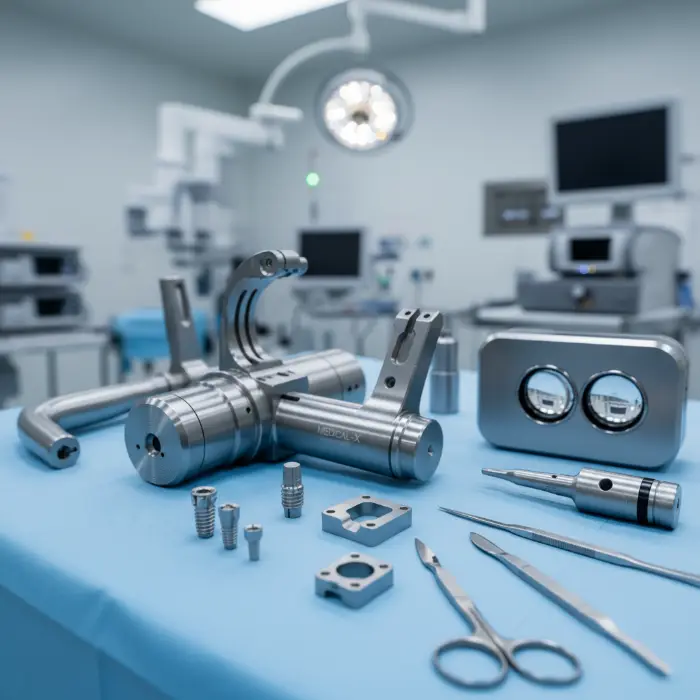

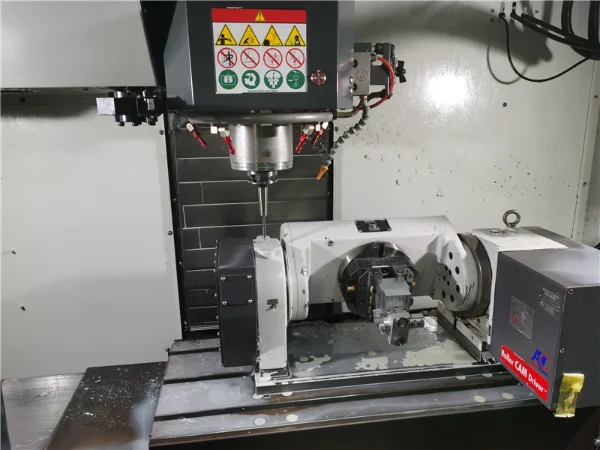

The cnc machining medical industry plays a critical role in modern medical device development, diagnostic equipment manufacturing, and precision healthcare solutions. As medical technology continues to demand smaller tolerances, cleaner finishes, and higher reliability, CNC machining has become one of the most trusted manufacturing methods in the medical industry.

Overview:

Material:aluminum alloy,stainless steel,titanium alloy,magnesium alloy,other polymer plastic such as peek,ptfe,pom etc.

Application :Surgical Instruments & Handheld Tools,Medical Device Housings & Structural Parts,Diagnostic & Laboratory Equipment Components,Implant & Medical Trial Components.

Tolerance:±0.05 mm~±0.005mm

MOQ:1-500 PCs

Sample delivery:1-3 days

Price:20~300 USD/PCs

Why CNC Machining Is Essential in the Medical Industry

The medical industry requires components that meet extremely high standards for precision, safety, and consistency. CNC machining medical industry applications provide the level of control necessary to manufacture parts that directly affect patient care and device performance.

Key reasons CNC machining is essential in the medical industry include:

Tight dimensional tolerances for functional accuracy

Excellent surface quality for hygiene and safety

Stable and repeatable production for regulated devices

Rapid iteration for medical prototype development

For many manufacturers, cnc machining medical industry solutions are the preferred choice for both early-stage development and long-term production.

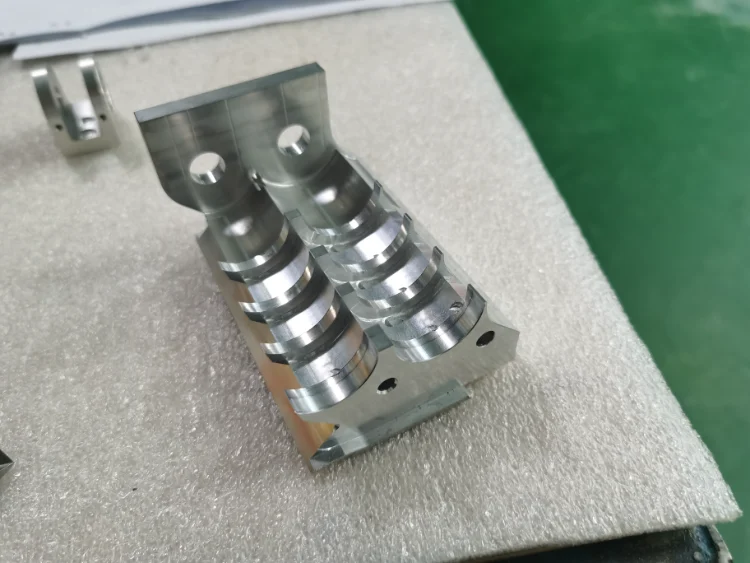

Medical Components Commonly Produced by CNC Machining

Surgical Instruments & Handheld Tools

CNC machining medical industry processes are used to produce surgical instruments such as forceps, clamps, cutters, and handles, ensuring precise geometry, smooth surfaces, and reliable performance through repeated sterilization.

Medical Device Housings & Structural Parts

Medical CNC machining is widely applied to housings, frames, brackets, and enclosures that protect sensitive electronics and maintain structural stability in medical equipment.

Diagnostic & Laboratory Equipment Components

CNC machining medical industry solutions support diagnostic and laboratory devices requiring high dimensional accuracy, clean assembly, and consistent fit.

Implant & Medical Trial Components

CNC machining is commonly used to manufacture medical trial parts, surgical guides, and functional prototypes during the development and validation stage.

Materials Used in CNC Machining Medical Industry Projects

Material selection is one of the most important aspects of medical CNC machining. The cnc machining medical industry relies on both medical-grade metals and engineering plastics.

Metal cnc material type:

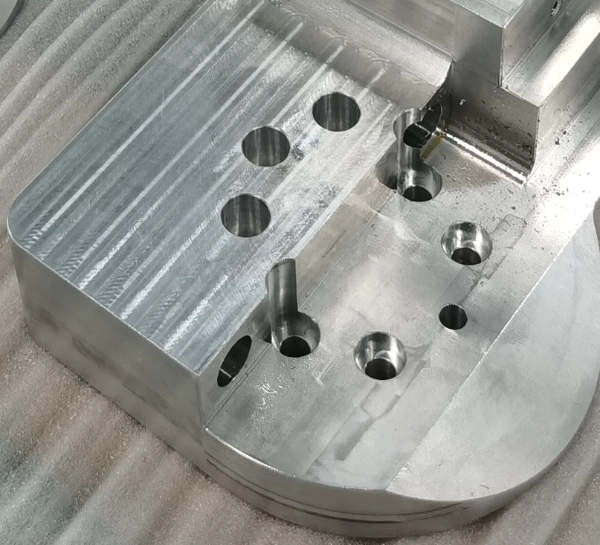

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Titanium

Titanium is widely used in medical CNC machining due to its excellent biocompatibility, high strength-to-weight ratio, and outstanding corrosion resistance. It is commonly applied in orthopedic implants, dental components, surgical instruments, and medical device structures where long-term reliability and patient safety are critical.

Color : Silver-gray.

Types : Titanium Grade 2 / Grade 5 (Ti-6Al-4V) / Grade 23 (Ti-6Al-4V ELI) / Grade 1 / Grade 9 / Medical-grade titanium alloys.

Surface finish : Polishing, Sandblasting, Passivation, Anodizing (color anodizing), Electropolishing, Acid etching, Pickling.

Delivery time : 3–7 days.

Plastic cnc material type:

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

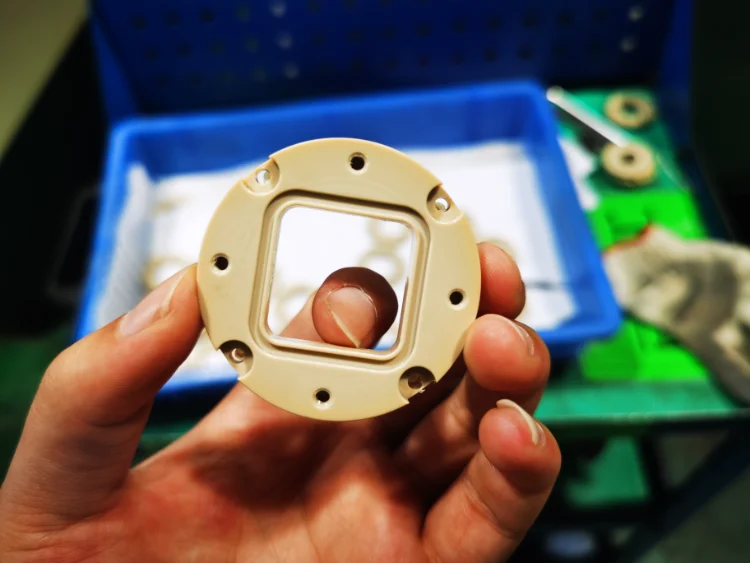

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

Surface Finishing for Medical CNC Parts

Surface finishing is a critical step in the cnc machining medical industry, influencing corrosion resistance, cleanability, and appearance.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals such as aluminum, magnesium, and titanium.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Electropolish

Removes microscopic protrusions from metal surfaces through electrochemical anodic dissolution, creating a smooth, dense surface free of residual stress and highly corrosion-resistant. Capable of processing complex metals and conductive materials.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, this process enhances hardness, strength, toughness, and wear resistance. It is suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Precision & Tolerance Standards in Medical CNC Machining

Medical components often require much tighter tolerances than standard industrial parts. In cnc machining medical industry applications, precision directly affects device performance and safety.

Typical capability includes:

Standard tolerances: ±0.05 mm

Precision tolerances: ±0.01–0.02 mm

Controlled surface roughness for easy cleaning and sterilization

High-precision medical machining ensures proper assembly, alignment, and long-term reliability.

Medical CNC Machining Prototypes vs Production

Medical CNC Machining Prototypes

The cnc machining medical industry is heavily involved in prototype development. CNC machining enables rapid testing of form, fit, and function before regulatory approval or full production.

Low- to Mid-Volume Medical Production

Many medical devices require controlled-volume manufacturing rather than mass production. CNC machining medical industry manufacturers support consistent quality across small and medium batch sizes.

Quality Control & Compliance

Quality assurance is essential in the cnc machining medical industry. Professional medical machining suppliers implement strict inspection and documentation procedures, including:

Dimensional inspection and CMM measurement

Material traceability and verification

In-process quality control

Documentation support for medical requirements

These measures help reduce risk and ensure compliance with industry standards.

How CNC Machining Benefits Medical Manufacturers

CNC machining medical industry services provide clear advantages to medical device manufacturers:

Faster product development cycles

Reliable dimensional accuracy

Flexible material selection

Reduced manufacturing risk

Support for innovation and customization

CNC machining enables medical companies to move from concept to functional product with confidence.

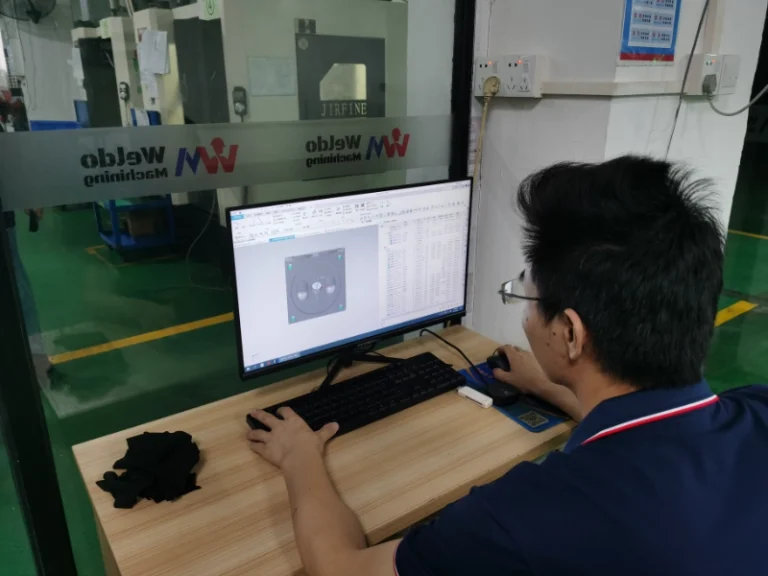

Why Choose Us for CNC Machining Medical Industry Projects

Choosing an experienced supplier is critical for medical manufacturing success. A professional cnc machining medical industry partner provides engineering support, advanced machining capability, and controlled processes that meet the demands of healthcare applications.

With expertise in precision machining, medical materials, and prototype-to-production workflows, Weldo machining support medical manufacturers at every stage of development.

FAQ of cnc machining medical industry

Why is titanium commonly used in medical CNC machining?

Because it offers excellent biocompatibility, corrosion resistance, and high strength with low weight.

Is titanium CNC machining more difficult than stainless steel?

Yes. Titanium generates more heat and requires slower cutting speeds and rigid tooling.

Can titanium medical parts be surface treated?

Yes. Common finishes include polishing, anodizing, passivation, and electropolishing.

Is titanium suitable for medical prototypes and production?

Yes. CNC machining supports both medical prototypes and low- to medium-volume production.