Overmolding

Overmolding machining integrates multiple materials to enhance product performance (such as waterproofing and impact resistance) and improve tactile feel while streamlining production processes. It is suitable for diverse industries. For detailed process information or to request a quote, please contact us Weldo !

What is overmolding ?

Overmolding is a manufacturing technique that integrates two or more materials into a single unit through injection molding. Typically, a rigid substrate serves as the base layer, achieving adhesive-free bonding between materials via physical interlocking or chemical molecular affinity. This process is categorized into two-shot molding and insert molding. The former completes the process within a single production cycle using a rotating mold, while the latter requires transferring the substrate to a second mold for injection.

Material for Overmolding

The base materials are predominantly rigid (engineering plastics/metals), while the overmolding materials are mostly elastomers or soft plastics, providing a soft tactile feel, slip resistance, or sealing functionality.

The following are optional materials.

Metal material :

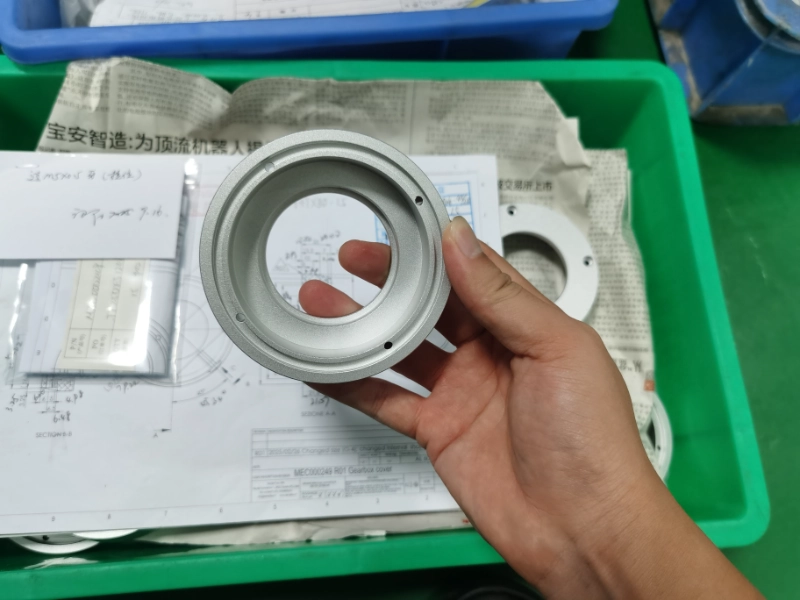

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

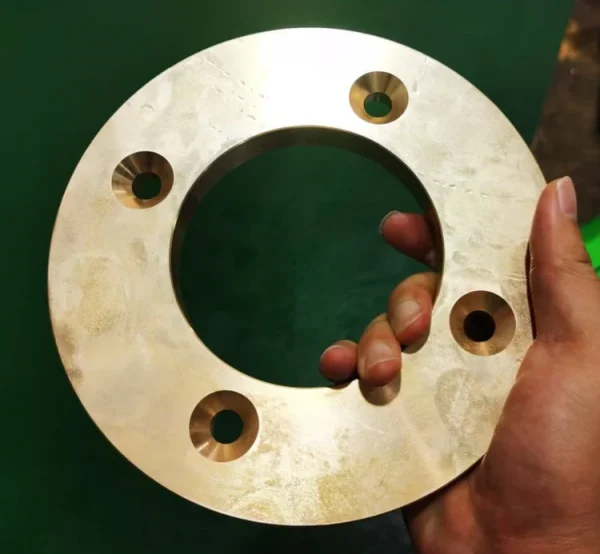

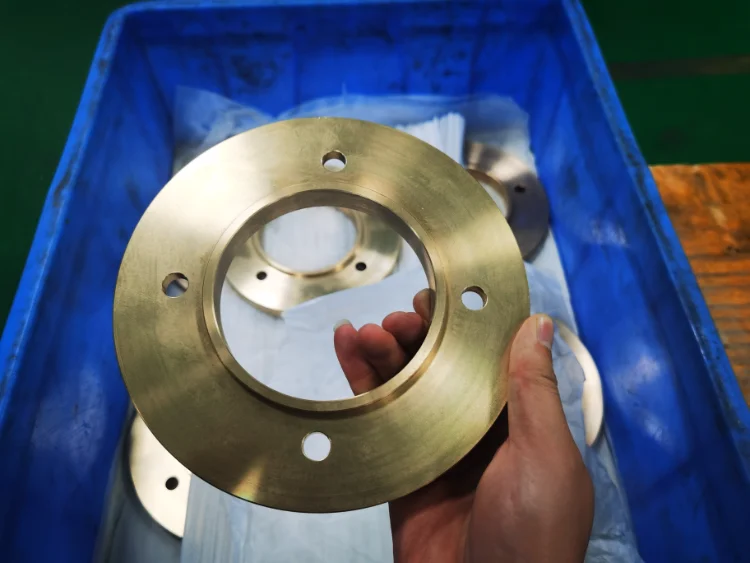

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

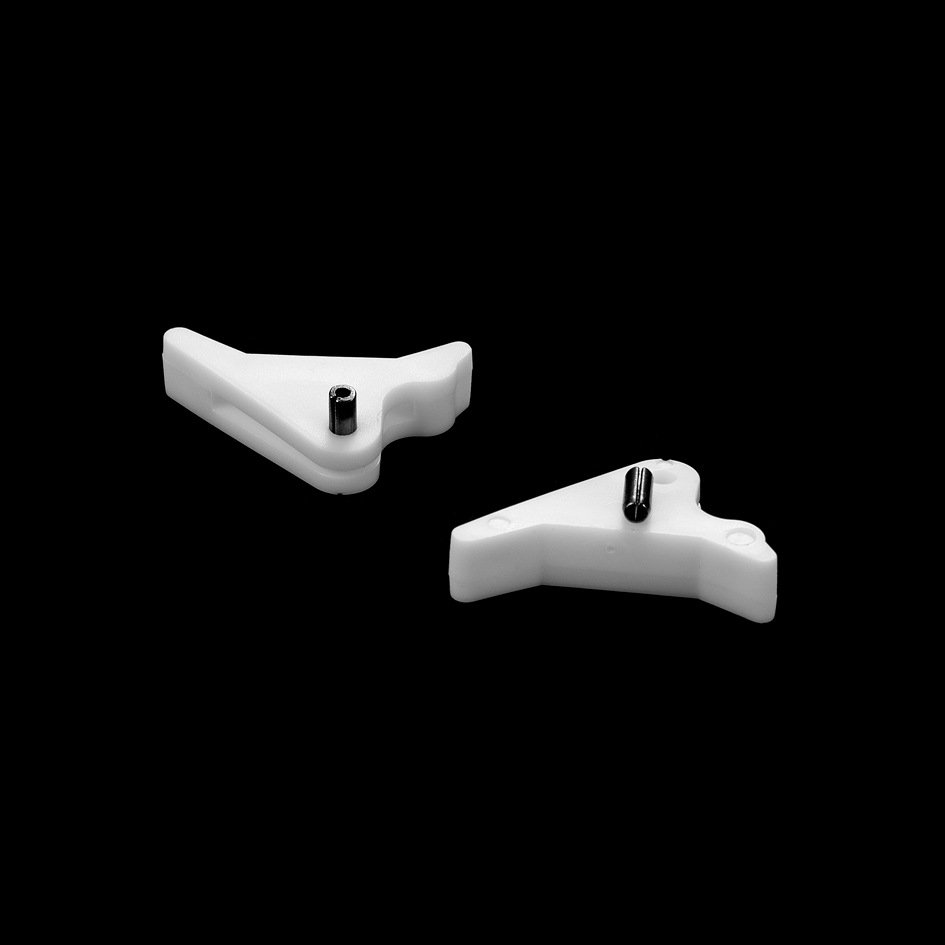

Plastic material :

ABS

Combining the rigidity of acrylonitrile, the toughness of butadiene, and the processability of styrene, it offers excellent impact resistance (maintaining toughness even at low temperatures) with a balanced hardness and rigidity. Suitable for precision components subjected to moderate loads, it is ideal for manufacturing precision parts such as electronic and electrical enclosures, automotive ducting, interior trim components, and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HIPS

HIPS is a non-crystalline thermoplastic containing 5-15% rubber content, offering both high impact resistance and ease of processing. It features moderate surface hardness, low moisture absorption (0.05-0.7%), low cost, and suitability for complex structures. Widely used in appliance housings, food packaging, automotive interiors, and industrial piping, it replaces metal to meet lightweight and impact-resistant requirements.

Color : black.

Types : Impact-resistant HIPS, Brominated flame-retardant HIPS, Glass-fiber reinforced HIPS.

Surface finish :Polishing ,Sandblasting ,Coating.

Delivery time : 1-5 days.

Common Material Combinations:

PP Base + TPE Overmolding: Widely used in tool handles, daily necessities, etc.

ABS Base + Silicone Overmolding: Used for products requiring high-temperature resistance or food-grade contact.

PC Base + Soft PVC Overmolding: Used for electronic device housings, providing slip resistance and cushioning.

Metal Base + TPU Overmolding: Used for automotive components or industrial equipment, enhancing grip and impact resistance.

…

Overmolding capability

| ITEM | SPECIFICATION |

|---|---|

| FORMING ACCURACY | Dimensional tolerance ±0.05mm (general parts), ±0.02mm (precision parts), weight deviation of same-model products ≤1% |

| PRODUCTION EFFICIENCY | Standard cycle time 30-90 seconds/mold, mold change time ≤25 minutes |

| MAXIMUM MACHINING SIZE | 500×400×200mm |

| MAXIMUM WEIGHT OF METAL INSERT | 3kg |

| SUBSTRATE PREHEATING TEMPERATURE | 80-120°C (metal), 40-60°C (plastic) |

| MELT TEMPERATURE DIFFERENCE CONTROL | ≤10°C (to avoid internal stress) |

| HOLDING PRESSURE GRADIENT | 60-80bar (segmented control) |

Overmolding guideline

Overmolding requires precise process control and strict quality standards to ensure strong material bonding and consistent part performance. The following tables summarize key overmolding inspection criteria, common issues, and corresponding solutions to support stable and reliable overmolding production.

| TESTING ITEM | TESTING STANDARD | TESTING METHOD |

|---|---|---|

| Dimensional Accuracy | ±0.05mm | CMM Inspection |

| Adhesion | ≥6N/mm² | Peel Test |

| Color Difference ΔE | ≤1.0 | Spectrophotometer |

| Glue Overflow | Not Visible | Visual Inspection/Microscope |

| Defects | No Bubbles, No Burn Marks | Visual Inspection |

| PROBLEM | CAUSE | SOLUTION |

|---|---|---|

| Overmolding Detachment | Material Incompatibility or Insufficient Temperature | Select Compatible Material System, Increase Mold Temperature |

| Glue Overflow | Insufficient Mold Closing Accuracy | Check Clamping Force, Repair Mold |

| Bubbles | First Shot Contains Moisture or Uneven Cooling | Improve Drying, Increase Mold Temperature |

| Whitening at Joint | Excessive Injection Speed | Reduce Injection Speed, Improve Venting |

Advantage of overmolding

Reduced assembly steps: Multi-component integrated molding eliminates adhesive bonding or mechanical connections, reducing labor costs by 40% in a specific automotive component case.

Enhanced product durability: Molecular-level bonding between materials boosts impact resistance by 200% and achieves weather resistance from -40°C to 80°C.

High design flexibility: Enables complex geometric structures and functional integration (e.g., sealing + anti-slip + conductivity in one part).

Flexible Material Combination: Supports metal/plastic and rigid/flexible material composites (e.g., Aluminum Alloy + TPU, PC + LSR)

Optimized Production Efficiency: Single-mold processing reduces logistics turnover; paired with SMED rapid mold change, shortens small-batch order lead times by 50%

Application of overmolding parts

Automotive Industry: Steering wheel multifunction buttons (PC+TPE), sensor seals (PA66+silicone)

Medical Devices: Surgical instrument grips (Stainless Steel 316+LSR), IV connector interfaces (ABS+soft rubber)

Consumer Electronics: Smartwatch straps (Aluminum Alloy+TPU), earphone charging cases (PC + silicone waterproof gasket)

Home Appliances: Coffee machine handles (PA66 + glass fiber + TPV), vacuum cleaner grips (PP + EPDM)

Industrial Components: Robot end effectors (aluminum alloy + rubber), sensor housings (PBT + sealing rings)

FAQ of Overmolding

How to resolve poor material adhesion issues?

① Increase contact area by laser etching the substrate surface (line width 50μm);

② Select compatible grades (e.g., Versaflex OM series specifically for PC/ABS overmolding);

③ Control mold temperature difference ≤10℃.

Does the metal substrate require preheating?

For aluminum/magnesium alloys thicker than 3mm, preheat to 120-150°C to prevent internal stress cracking in the overmolded layer due to rapid cooling.

What is the mold life for LSR overmolding?

Using S136 mold steel (hardness HRC 52-54) with silicone rubber-specific release agents achieves a lifespan exceeding 500,000 cycles.

How to calculate the optimal overmold thickness?

Follow the substrate thickness: overmolded layer = 3:1 principle (e.g., 2mm substrate corresponds to 0.6-0.7mm overmolded layer). Excessive thickness may cause sink marks, while insufficient thickness compromises bond strength.

How to achieve rapid mold change during mass production?

Employ SMED rapid mold change technology. Utilizing standardized mold locating pins (tolerance ±0.01mm) and a preheating system reduces changeover time to under 25 minutes.