3D Printing

Overview

Our 3D printing can quickly turn your ideas into tangible objects. Send us your design for a quote—it saves time, effort, and money. Give it a try today!

Tolerance:

FDM (Fused Deposition Modeling):±0.20–0.50 mm or ±0.5%

SLA (Resin Printing) :±0.10–0.15 mm

SLS (Nylon Powder Printing):±0.20–0.30 mm

MJF (Multi Jet Fusion) :±0.20 mm

DMLS/SLM (Metal 3D Printing) :±0.05–0.10 mm.

Application:Prototyping,aerospace,automotive,medical,Consumer

Delivery time:1-5 days

Price:10-500 USD/PCs

What is 3d printing ?

3D printing (additive manufacturing) is a technology that constructs three-dimensional objects from digital models by layering materials (plastics, metals, resins, etc.). Compared to traditional subtractive manufacturing, it achieves material utilization rates exceeding 95%. Core processes include:

FDM (Fused Deposition Modeling): Suitable for plastic prototypes, low cost but limited precision (±0.5mm)

SLA (Stereolithography): High-precision resin printing with accuracy of ±0.1mm and surface finish Ra≤1.6μm

SLS (Selective Laser Sintering): Sintering of metal/plastic powders, supporting complex geometries (e.g., hollow parts, lattice structures)

Material for 3d printing

Supports dozens of materials including PLA, ABS, nylon, aluminum alloy, and stainless steel, capable of handling everything from prototyping to mass production. 3D printing delivers precise forming, and when combined with CNC machining and laser cutting, complex structures become easily achievable. Below are our primary production materials:

Metal material :

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

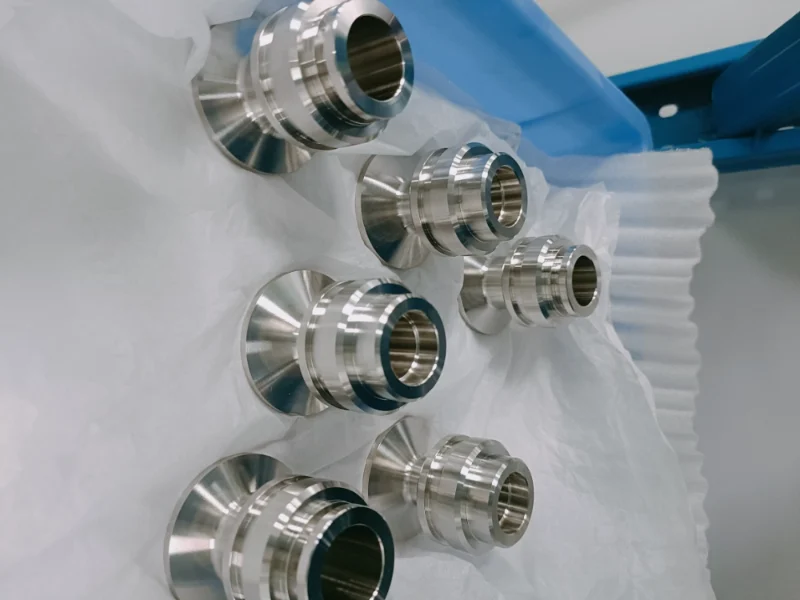

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Plastic material :

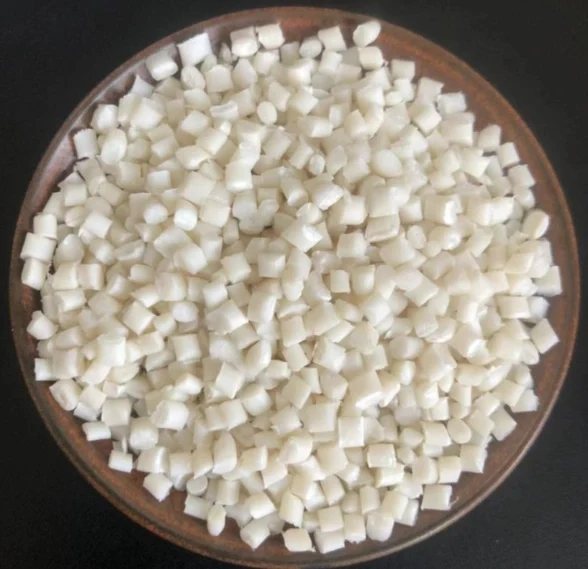

PLA

PLA (polylactic acid) is a bio-based biodegradable material produced through the fermentation of starch extracted from renewable resources such as corn and sugarcane. It is environmentally friendly and non-polluting, ultimately degrading into carbon dioxide and water.Primarily manufactures lightweight tool handles, gears, bearing housings, figurines, cosplay props, and more.

Color : white,black,grey,red,green,blue,yellow, etc.

Types : Pure PLA, Modified PLA, Composite PLA, Food-grade/Medical-grade PLA.

Surface finish :Grinding and polishing, chemical treatment, spraying and electroplating, plasma treatment, surface coating, heat treatment.

Delivery time : 1-5 days.

ABS

Combining the rigidity of acrylonitrile, the toughness of butadiene, and the processability of styrene, it offers excellent impact resistance (maintaining toughness even at low temperatures) with a balanced hardness and rigidity. Suitable for precision components subjected to moderate loads, it is ideal for manufacturing precision parts such as electronic and electrical enclosures, automotive ducting, interior trim components, and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

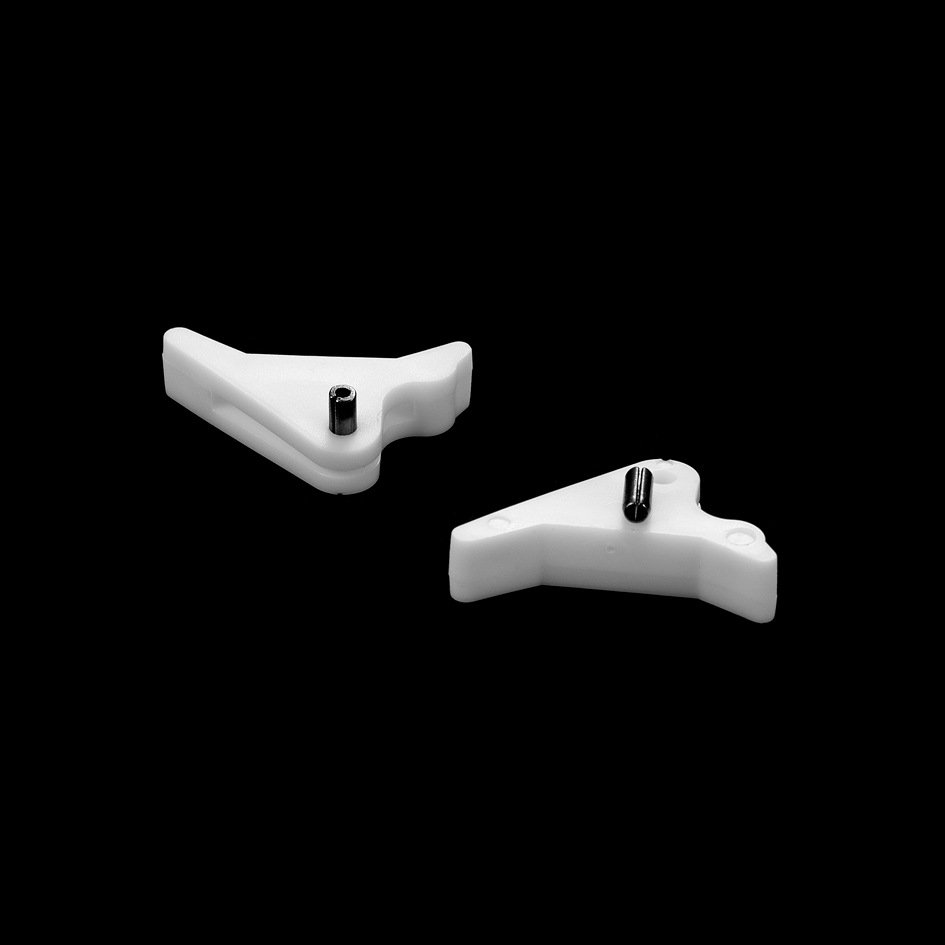

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

3D printing capability

| ITEM | SPECIFICATION |

|---|---|

| MAXIMUM VOLUME | 750×550×550mm, Precision ±0.05mm |

| MINIMUM WALL THICKNESS | ≥0.8mm (FDM) / 0.3mm (SLA) |

| HOLE DIAMETER | ≥1.5mm |

| DIMENSIONAL TOLERANCE | Precision Grade ±0.1mm,Standard Grade ±0.3mm |

3D printing guide

| ITEM | SPECIFICATION |

|---|---|

| LAYER THICKNESS | Fine models: 0.05-0.1mm; Quick prototypes: 0.2mm |

| INFILL DENSITY | Structural parts: 70%-100%; Decorative parts: down to 20% |

| SUPPORT STRUCTURE | Add soluble or manually removable supports for complex models to avoid sagging in overhanging areas. |

| FIRST LAYER INSPECTION | Observe whether the first layer adheres evenly. Readjust if the edges lift. |

| MID-PRINT INSPECTION | Check material level and nozzle status every 2-3 hours to prevent running out of material or clogging. |

| ENVIRONMENT CONTROL | Maintain stable temperature (18-28°C) and avoid material absorption of moisture. |

Advantage of 3d printing

Design Freedom: Enables integrated molding of complex structures (e.g., topology-optimized parts, lattice supports) unattainable through traditional manufacturing methods

Rapid Iteration: Reduces product development cycles by 60%; a certain automotive component achieved design-to-prototype in just 3 days

Material Utilization: Powder bed process achieves >90% material recovery rate, saving 70% material compared to milling

Customized Production: Enables patient-specific implants in medical applications (e.g., titanium alloy cranial repair plates)

Weight Reduction: Aeronautical components achieve 30% weight reduction, boosting fuel efficiency by 15%.

Application of 3d printing

Medical:Applications in healthcare include customized prosthetics, dental braces, surgical guides, and bioprinting (e.g., skin, organs).

Automotive:3D printing is used to manufacture automotive components, prototype vehicles, and customized interior fittings.

Consumer Electronics:It produces casings and internal structural parts for consumer devices like smartphones and headphones.

Architecture:3D printing enables the creation of architectural models, aiding designers and clients in visualizing design concepts.

Education:3D printing provides tangible teaching tools for educational settings, helping students better comprehend three-dimensional spaces and object structures.

FAQ of 3D printing

How to Address Surface Roughness in 3D Printed Parts?

① For SLA printing: Use 10μm layer thickness + post-curing (UV at 60°C for 2 hours);

② For FDM, use a 0.4mm nozzle + cooling fan at full speed

What are the key post-processing steps for metal 3D printing?

① Powder removal (sandblasting at 0.3MPa pressure);

② Hot isostatic pressing (HIP at 1200℃/100MPa) to eliminate internal voids;

③ CNC finishing (achieving ±0.02mm precision)

How to choose between PLA and ABS printing?

PLA is suitable for low-stress applications (models, teaching aids), while ABS is ideal for functional testing (e.g., snap-fit structures, impact-resistant components).

How to prevent warping in large-scale prints?

① Increase heated bed temperature to 110°C (ABS);

② Enable “Brim” (5mm width);

③ Maintain ambient printing temperature at 25±2°C.