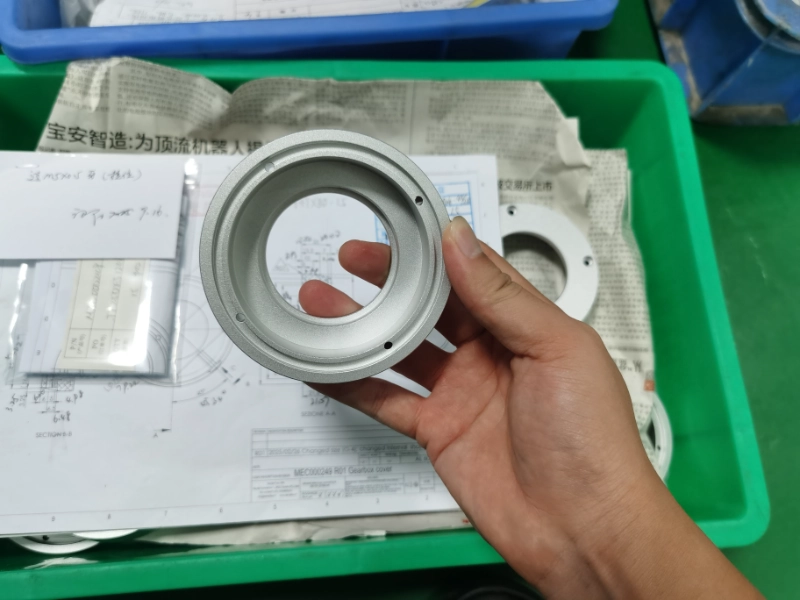

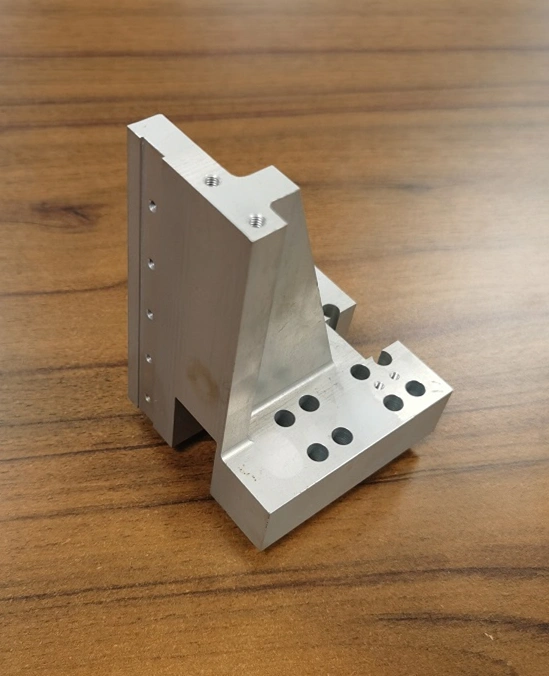

CNC machining aluminum

Get competitive price for custom CNC machining (manufactured) aluminum parts. Receive comprehensive quotes for other type of aluminum materials and additional surface finishing processes for high-standard prototypes and standard production-run parts.

Price : 10-50 usd /pcs

Lead time : 1-5 days

Wall thickness : 0.5-1 mm

Tolerance : 0.01 mm

Max size part :1000 mm* 1000 mm* 500 mm

Key Characteristics of Aluminum in CNC Machining

Lightweight: Density approximately 2.7 g/cm³,Good strength,Easy machinability,Excellent thermal conductivity and heat dissipation,High corrosion resistance,Suitable for surface treatments

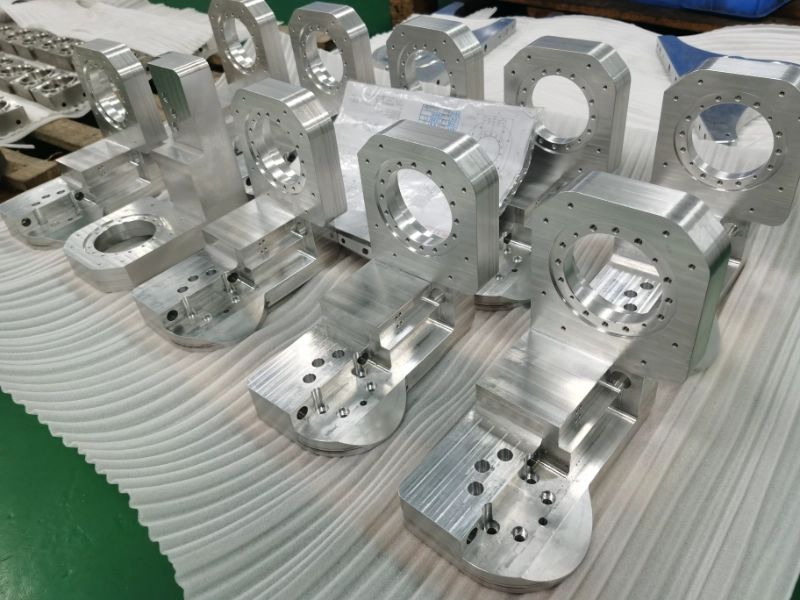

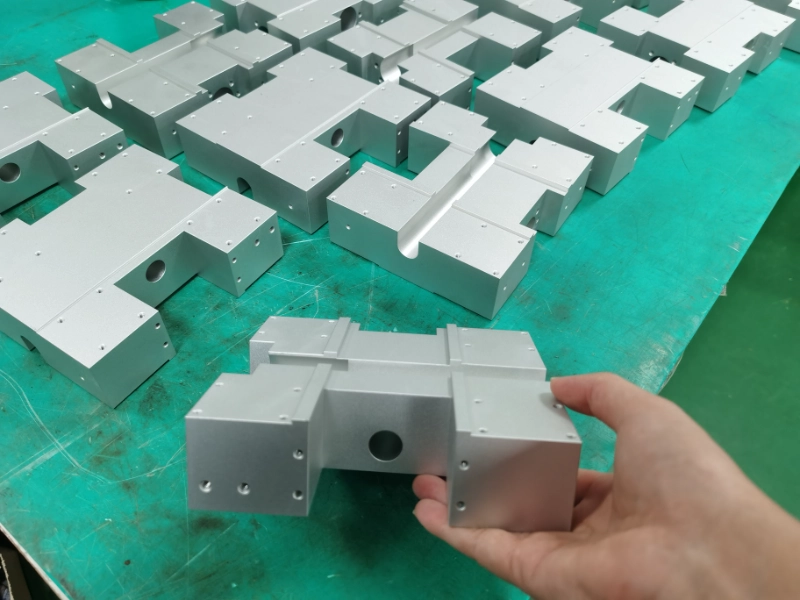

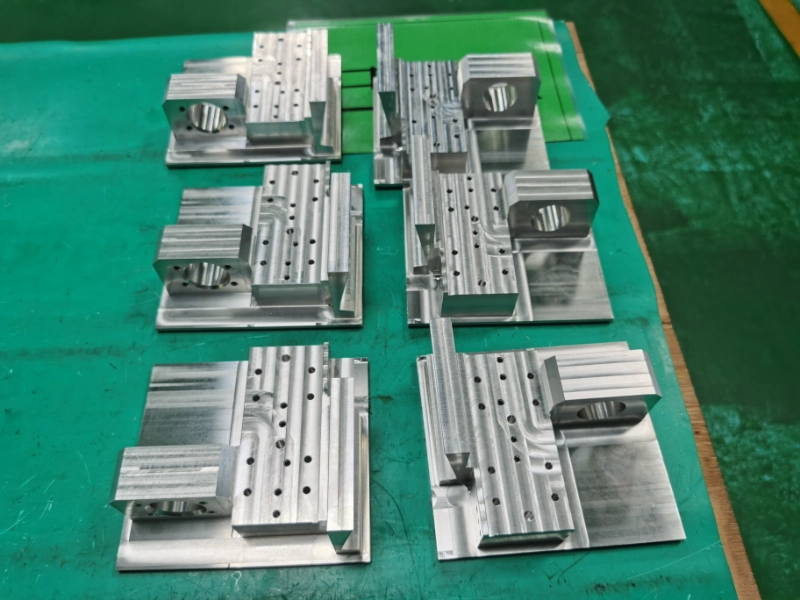

Applications of CNC Aluminum

Aerospace: Structural components, brackets, airframe parts.

Automotive Industry: Engine components, wheel hubs, structural parts, lightweight components.

Electronics: Mobile phone casings, laptop enclosures, heat sinks, electronic component brackets.

Medical Devices: Enclosures, surgical instruments, rehabilitation equipment parts.

Machinery Components: Fixtures, housings, support structures, gears, connectors.

Consumer Goods: Sports equipment, bicycle parts, home appliance components.

Common CNC Aluminum Alloy Materials

6061 Aluminum Alloy(7075,6060 ,6082 ,5083,6063 ,5052 ,2024,7050 ,MIC6,2017A )

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Fatigue Strength (MPa) | Elongation (%) | Hardness (HB) | Density (g/cm³) |

|---|---|---|---|---|---|---|

| 6061-T6 | 290–320 | 270–280 | 90–100 | 12–17 | 95–100 | 2.70 |

| 6061-T5 | 240–260 | 215–240 | 85–95 | 10–16 | 85–95 | 2.70 |

| 7075-T6 | 540–572 | 480–510 | 150–160 | 10–12 | 150–160 | 2.81 |

| 6060-T6 | 180–200 | 140–160 | 50–60 | 8–12 | 70–80 | 2.70 |

| 6082-T6 | 310–340 | 270–310 | 85–95 | 8–12 | 90–100 | 2.70 |

| 5083-H116 | 275–317 | 125–228 | 80–95 | 10–17 | 70–80 | 2.66 |

| 6063-T6 | 220–240 | 200–215 | 60–70 | 8–12 | 70–75 | 2.70 |

| 5052-H32 | 210–230 | 150–193 | 90–100 | 12–18 | 60–70 | 2.68 |

| 2024-T3 | 455–470 | 310–325 | 120–138 | 18–20 | 120–130 | 2.78 |

| 7050-T7451 | 510–524 | 430–455 | 150–160 | 9–12 | 145–155 | 2.83 |

| MIC-6 (cast) | 150–170 | 100–130 | — | 3–4 | 60–70 | 2.70 |

| 2017A-T4 | 410–430 | 260–275 | 110–120 | 10–18 | 115–125 | 2.78 |

Application fields of different CNC aluminum alloy materials

| Alloy | Applications |

|---|---|

| 6061 (T6/T5) |

Aircraft parts, automotive components, bicycle frames, marine fittings Mechanical structures, mold base plates A widely used "universal alloy" with medium strength and good corrosion resistance |

| 7075 (T6) |

Aerospace structures (wings, fuselage frames) Military equipment, high-stress parts (gears, connecting rods, shafts) High-strength sports equipment (carabiners, bicycle components) |

| 6060 (T6) |

Architectural profiles (window frames, curtain walls, pipes) Furniture and decorative parts Electrical and light-duty structural components |

| 6082 (T6) |

Bridges, cranes, marine engineering structures High-strength structural parts, vehicle frames Commonly used high-strength alloy in construction and machinery |

| 5083 (H116) |

Shipbuilding (hulls, decks, offshore platforms) Pressure vessels, cryogenic containers (LNG tanks, liquid nitrogen vessels) Structural parts in marine environments (excellent seawater corrosion resistance) |

| 6063 (T6) |

Architectural profiles (doors, windows, curtain walls, railings) Decorative trims, pipes, furniture frames Structural components with high surface quality and corrosion resistance |

| 5052 (H32) |

Fuel tanks, fuel pipes, marine components Cookware, appliance housings, signage Automotive and lightweight transportation parts |

| 2024 (T3) |

Aircraft structures, fasteners (screws, bolts) Automotive parts (connecting rods, wheels) Military equipment (preferred in aerospace) |

| 7050 (T7451) |

Aircraft structures (wing spars, fuselage frames, landing gear parts) High-strength load-bearing components with excellent resistance to exfoliation and stress corrosion cracking Aerospace and military applications |

| MIC-6 (Cast) |

Precision fixtures, jigs, base plates CNC machining tooling, mold plates Parts requiring dimensional stability (not suitable for high-load applications) |

| 2017A (T4) |

Aircraft structures, propeller components Automotive and military parts Rivets, fasteners (a typical duralumin alloy) |

Multi Surface finishes for cnc machined aluminum part

| Treatment | Features | Applications |

|---|---|---|

| Anodizing | Improves corrosion resistance, hardness, can be colored (black, silver, red, etc.) | Common for appearance parts and structural components |

| Hard Anodizing | Thicker and harder oxide layer, excellent wear resistance | Aerospace, military, and high-durability parts |

| Sandblasting / Bead Blasting | Creates a uniform matte finish, removes burrs, enhances texture | Surface preparation and decorative finishing |

| Polishing | Increases brightness, mirror-like surface | Decorative and aesthetic parts |

| Electroplating | Nickel, chrome, or gold plating; enhances wear resistance and appearance | Functional and decorative applications |

| Powder Coating | Organic powder coating, rich colors, excellent corrosion resistance | Outdoor equipment, consumer products, automotive |

| Chemical Conversion Coating (e.g., Alodine) | Thin protective layer, maintains electrical conductivity | Electrical and aerospace components |

| Brushing | Creates regular linear texture, improves aesthetics | Electronic housings, decorative surfaces |

Pro and cons of aluminum cnc machining

Aluminum cnc machining FAQ

1. What are the advantages of CNC machining aluminum ?

Aluminum offers excellent machinability, and CNC machining allows for precise, complex shapes to be produced. Its lightweight, high strength, and corrosion resistance make it widely used in industries such as aerospace, automotive, and electronics.

2.What is the typical lead time for CNC machining aluminum parts ?

Lead time for CNC machining aluminum parts typically ranges from a few days to a couple of weeks, depending on the complexity of the part, material availability, and production schedule. Rush orders may be possible with additional costs for expedited processing.

3.How can aluminum machining distortion be minimized ?

To minimize distortion in aluminum during CNC machining, it is crucial to use appropriate cutting parameters, select the right tooling, and follow an optimal machining sequence. Additionally, controlling machining temperature and ensuring proper fixture setup helps reduce the risk of warping or distortion.