CNC TURNING SERVICE:

Custom CNC turning service :

Custom CNC turning services from prototype development to standardized mass production, delivering high-precision machining at competitive rates. Strict tolerances of 0.005 mm. Lead times: 1-3 days.

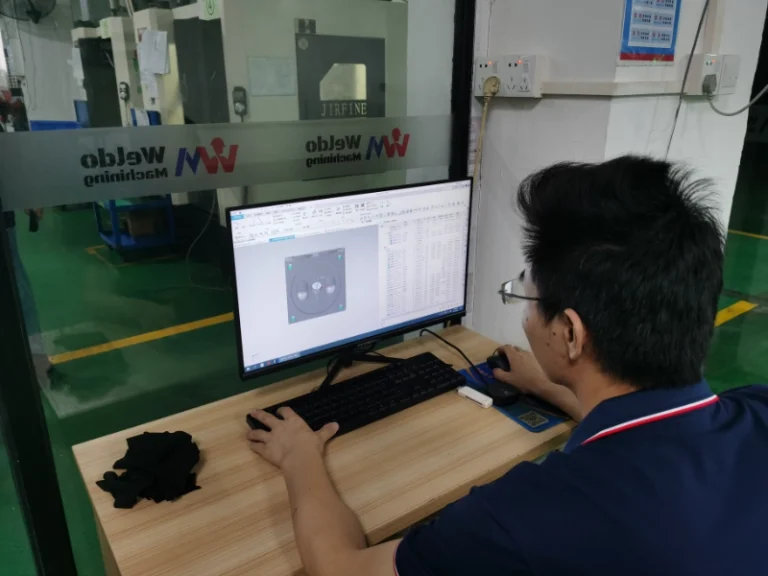

CNC Turning with Weldo machining

Weldo boasts over a decade of cnc turning expertise, offering services including external turning of bars and internal turning of axial holes. We select suitable metal materials or plastic components based on your project requirements and operating environment.We produce high-precision turned parts with expedited shipping available within 1 day.

Our precision CNC lathes efficiently remove excess material for features like axial (radial) bores, grooves, slots, and flat surfaces, delivering cost-effective, high-standard machining services.

Weldo CNC turning solution

Prototyping

Through our rapid prototyping and machining development services, we can transform your drawings into prototypes and molds within 1-3 days, helping you advance your design projects more efficiently.

Bulk precision machining

Whether for small-batch or large-scale standard machining production, we can strictly manufacture parts according to your drawing dimensions and precision requirements, ensuring the production of components that meet your expectations.

CNC Turning Common Materials

WELDO provides precision CNC turning services for materials ranging from common aluminum, stainless steel, alloys, and copper to plastics such as ABS and PC etc.

Metal cnc material type:

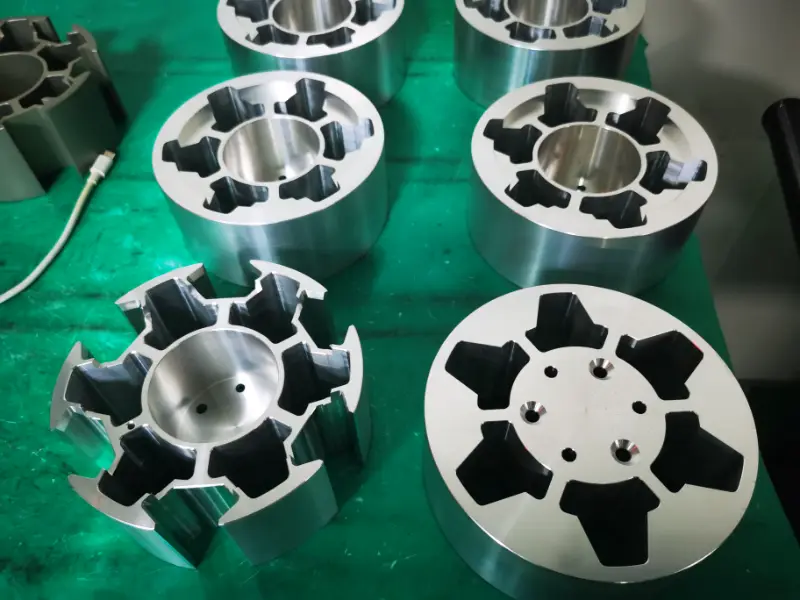

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Plastic cnc material type:

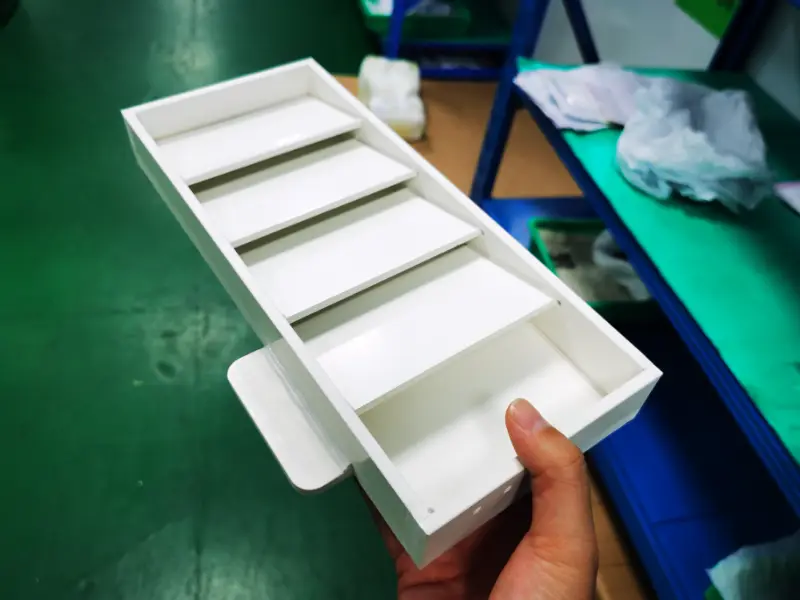

ABS

Combining the rigidity of acrylonitrile, the toughness of butadiene, and the processability of styrene, it offers excellent impact resistance (maintaining toughness even at low temperatures) with a balanced hardness and rigidity. Suitable for precision components subjected to moderate loads, it is ideal for manufacturing precision parts such as electronic and electrical enclosures, automotive ducting, interior trim components, and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PVC

Rigid PVC: Density approximately 1.35 g/cm³, high mechanical strength, tensile strength up to 34.5–49 MPa, elongation 20–40%, strong resistance to acids, alkalis, and oils, aging resistant, suitable for chemical and corrosive environments.

Color : White,Beige,black.

Types : Rigid PVC and Flexible PVC.

Surface finish : Painting and plating, polishing, sanding

Delivery time : 1-5 days.

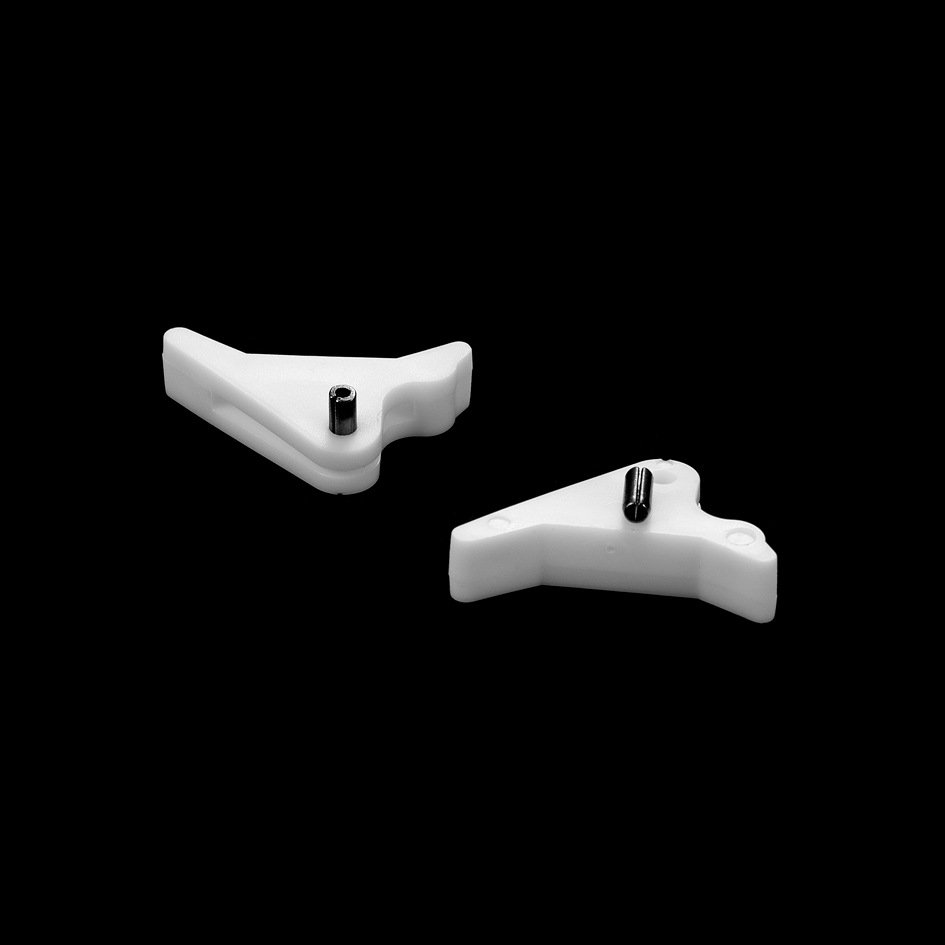

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

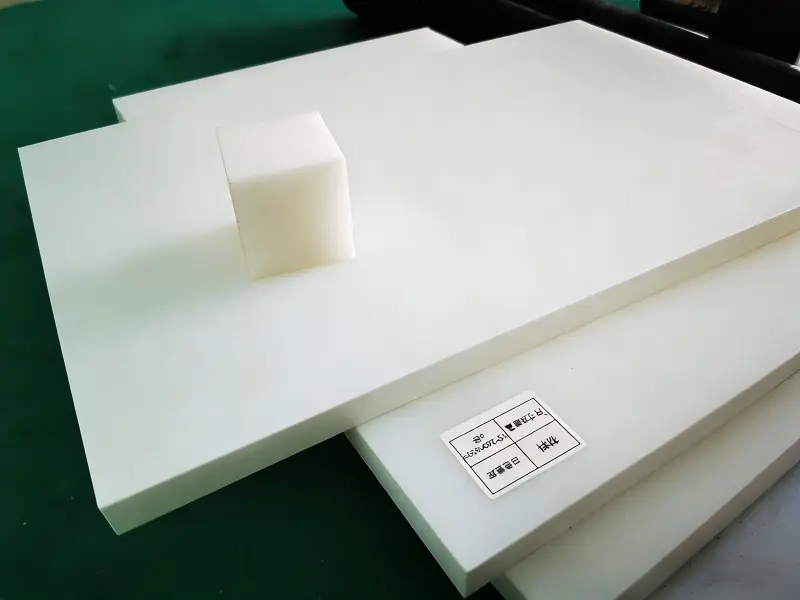

PTFE

PTFE is a high-performance engineering plastic with an extremely low friction coefficient, excellent chemical resistance, and outstanding electrical insulation. It remains stable across a wide temperature range and resists nearly all chemicals, solvents, and acids, making it ideal for precision parts such as seals, gaskets, bushings, insulators, and low-friction wear components used in chemical, medical, electronics, food, and aerospace industries.

Color : White, natural, black, filled or custom-colored.

Types : Virgin PTFE,Glass-filled PTFE,Carbon-filled PTFE,Bronze-filled PTFE,Modified PTFE

Surface finish : Machining finish, polishing, texturing, coating, engraving, anti-static treatment.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

FR4

FR4 is a glass-fiber-reinforced epoxy laminate with high mechanical strength, excellent electrical insulation, and strong dimensional stability. It offers good machinability, low moisture absorption, and reliable performance under mechanical load and elevated temperatures, and is commonly used for structural and insulating components such as electrical insulators, spacers, terminal blocks, mounting plates, fixtures, brackets, and support panels.

Color : Yellow, green, black, white, natural

Types : Standard FR4 / High-Tg FR4 / Halogen-free FR4

Surface finish : Machining finish, polishing, sandblasting, coating, painting, laser marking

Delivery time : 1–5 days

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HIPS

HIPS is a non-crystalline thermoplastic containing 5-15% rubber content, offering both high impact resistance and ease of processing. It features moderate surface hardness, low moisture absorption (0.05-0.7%), low cost, and suitability for complex structures. Widely used in appliance housings, food packaging, automotive interiors, and industrial piping, it replaces metal to meet lightweight and impact-resistant requirements.

Color : black.

Types : Impact-resistant HIPS, Brominated flame-retardant HIPS, Glass-fiber reinforced HIPS.

Surface finish :Polishing ,Sandblasting ,Coating.

Delivery time : 1-5 days.

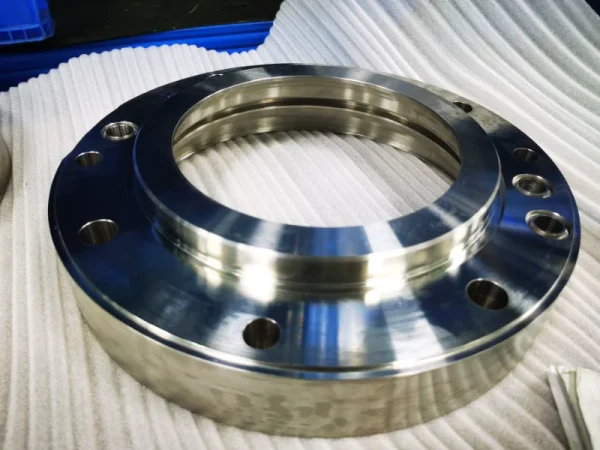

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

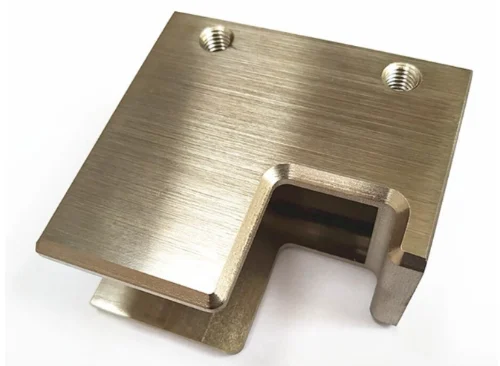

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

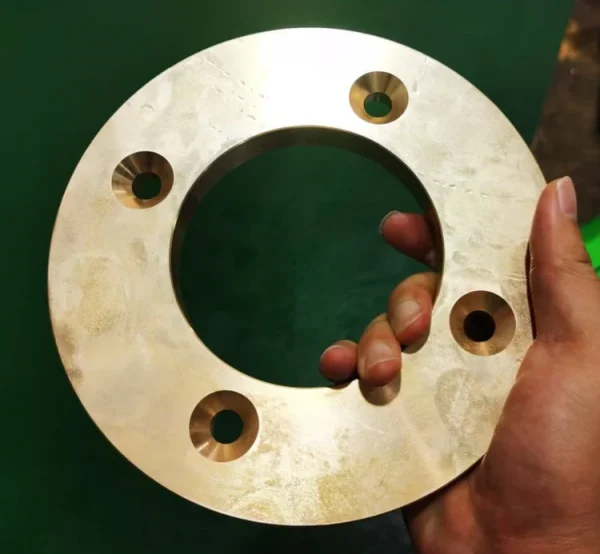

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

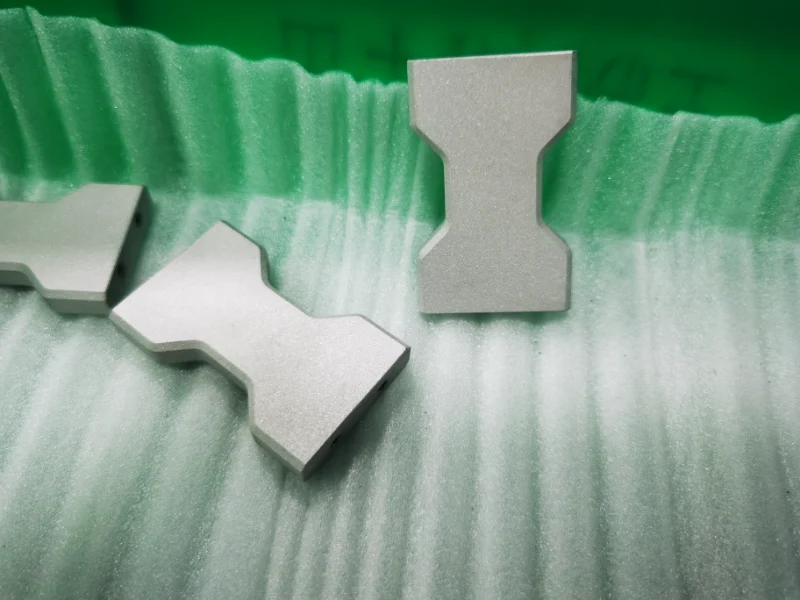

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Surface finish for CNC machining parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various turning machined parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Advantage of cnc turning service:

Advanced computer-controlled equipment ensures tight tolerances and high precision from outline to detailed dimensions, making it ideal for precision machining of both simple and complex geometries.

Automated processes significantly reduce manual intervention and shorten production cycles, ensuring efficient operation for both prototyping and mass production.

CNC turning can process a variety of materials, such as aluminum, steel, brass, and plastic, to customize parts for specific applications.

By minimizing material waste and workpiece damage, it achieves cost-effective manufacturing, making it suitable for both small and large-volume orders.

Tolerance for CNC turning

WELDO is ISO 9001 certified. We ensure precision machined parts meet stringent tolerance requirements. Our CNC lathes achieve tolerances as tight as ±0.005 inches. CNC metal turning precision complies with ISO 2768-m, while plastic turning precision adheres to ISO 2768-c tolerance standards.

| PROPERTY | DESCRIPTION |

|---|---|

| Maximum part size | The maximum direct machining diameter is 500mm, with a maximum machining length of 1200mm. For longer components requiring precision turning, we can adjust the equipment accordingly. |

| Minimum part size | The diameter is as small as 1 mm, depending on the specific part size requirements and material. |

| General tolerance | Our CNC turning standard tolerance is 0.01mm. If material and structure permit, tighter tolerances as low as ±0.005mm can be achieved. |

| Lead time | Prototype machining typically ships within 1-3 days. Small-batch CNC turning takes 3-5 days, with the fastest turnaround possible within 24-48 hours depending on part complexity and material. |

CNC turning design guilde

| ITEM | RECOMMENDED SIZE |

|---|---|

| Radii | The minimum inner radius should not be less than than 1 mm, with a maximum machining radius of 500 mm depending on the specific dimensional requirements and material of the part. |

| Threads and Tapped Holes | Capable of precision machining external and internal threads ranging from M1 to M50. To ensure thread stability, a minimum thread length of 1.5 times the diameter is recommended. |

| Minimum Wall Thickness | During CNC machining, the minimum recommended wall thickness for metals is 0.7 mm, while for plastics it is 1.5 mm. This ensures structural integrity of parts during turning and reduces costs. |

| Text | The minimum recommended engraving depth for characters is 0.2-2 mm, with a character height ranging from 1-10 mm. This depends on the material size and legibility requirements. |

| Holes | The minimum machinable hole diameter is 1 mm. For deep holes, it is recommended that the depth does not exceed five times the diameter to ensure part durability and quality. The maximum achievable depth is ten times the diameter. |

Start your cnc turning project

Upload your CAD/PDF files immediately. Our team will provide you with a quote, delivery time, and detailed part specifications within one hour (on business days). We specialize in CNC machining services for metals and plastics, with our own industrial park and mature logistics system to meet your product development needs.

Why choose us

Weldo is a leading service provider in the CNC turning industry, consistently delivering high-quality, cost-effective CNC turning services to global clients for over a decade. Our extensive experience in CNC machining enables us to produce high-precision prototypes and models for you.

High quality part

We dedicate sufficient focus and expertise to every task, ensuring our milling processes produce parts that meet customer precision requirements down to ±0.01mm, guaranteeing normal part functionality.

Fast lead time

Our dedicated production planners systematically manage each project, ensuring rapid prototype machining on CNC machines to help clients launch and complete projects efficiently

Engineering support

At every stage, we leverage our extensive milling expertise to maximize solutions for material selection, structural design, process optimization, and quality enhancement.

How does CNC turning work ?

CNC turning is a process that utilizes computer numerical control technology to pre-program instructions, directing the cutting tool to perform precision machining on metal or non-metal(plastic) materials (such as cylindrical, conical, threaded, and other symmetrical components).

The workpiece is secured to the spindle for rotation while the tool moves along the X-axis (radial) and Z-axis (axial) to remove excess material. The process involves rough turning, finish turning, grooving, threading, and other steps. Cutting fluid is used during operation to cool the workpiece and flush away chips.

Post-machining, parts typically undergo surface treatments like grinding, polishing, painting, or coating. Final inspection is conducted using vernier calipers, micrometers, and coordinate measuring machines to ensure parts meet customer precision requirements before shipment. The entire process requires minimal manual intervention, enabling high-standard, large-scale production.

Advantage of CNC turning

1. Ultra-High Precision

CNC systems precisely control cutting tools, limiting machining errors to the micrometer level (e.g., ±0.001mm). This ensures dimensional accuracy for products demanding extreme precision, such as aerospace components and medical implants.

2. Doubled Efficiency

Automated machining enables 24/7 uninterrupted operation with minimal human intervention. Multiple processes can be completed in a single setup, eliminating time lost to repeated part transfers and fixture adjustments, significantly boosting production efficiency.

3. Flexible Adaptability

CNC programs can be quickly modified to accommodate different workpiece requirements without changing equipment or tools. Seamless transition from prototype sampling to mass production is achievable, making it ideal for small-batch custom manufacturing.

4. Cost Optimization

Automation minimizes human error, improves material utilization, and reduces scrap rates. A single CNC lathe replaces multiple conventional machines, saving factory floor space and construction costs while lowering long-term operational expenses.

5. Consistent Quality

Computer control eliminates human variation, ensuring high consistency within batches. CNC programs log processing parameters, enabling rapid traceability of quality issues and process improvements.

CNC turning part application

Aerospace Industry

Engine components such as turbine shafts and combustion chamber assemblies designed to withstand extreme temperatures and pressures. Structural components including landing gear and wing attachments with complex, lightweight, and high-strength geometries.

Automotive Industry

Engine components such as crankshafts, camshafts, and pistons with low-friction surfaces to improve efficiency. Transmission components including gears and shafts, as well as chassis and suspension parts like steering knuckles and control arms.

Medical Industry

Implants such as artificial joints and bone fixation plates made from biocompatible titanium or cobalt-chromium alloys. Surgical instruments requiring micron-level precision, and diagnostic equipment components with high surface quality.

Energy & Industrial Equipment

Oil and gas components including corrosion-resistant valves, pump bodies, and pipeline fittings. Power equipment parts such as turbine blades and generator shafts, along with industrial machinery components like bearings and gearboxes for improved wear resistance.

Electronics & Precision Instruments

Lightweight, high-strength components for consumer electronics, including housings and connectors. Precision instruments such as optical lenses, sensors, and measuring components requiring micron-level accuracy.

CNC turning FAQ

What materials are suitable for CNC turning?

Metals: Aluminum alloys, stainless steel, titanium alloys, copper, etc. (commonly used in aerospace, automotive, and medical fields).

Plastics: Engineering plastics (e.g., PEEK, nylon), suitable for lightweight components like electronic device housings.

Composites: Some CNC turning equipment can process carbon fiber-reinforced composites.

How does CNC Turning ensure consistent quality?

Programmed control: CNC systems precisely record each machining step and parameter, guaranteeing identical dimensions for all parts within a batch.

Traceability: Machining data is permanently stored, enabling rapid root cause analysis and process optimization when quality issues arise.

Industry certifications: Complies with stringent quality management systems like ISO 13485 (medical) and AS9100 (aerospace).

Where does CNC Turning's cost advantage lie?

High material utilization: Automated cutting minimizes scrap, with defect rates controllable below 1% (traditional methods may reach 5%).

Reduced labor costs: A single CNC lathe replaces multiple conventional machines, saving factory space and manual intervention.

Long-term benefits: Though initial investment is high, overall costs decrease through enhanced productivity, lower defect rates, and reduced downtime.

What are the limitations of CNC turning?

Shape constraints: Primarily suited for rotationally symmetric parts (e.g., shafts, discs); complex 3D structures require CNC milling or 3D printing.

Size limitations: Restricted by machine table dimensions and spindle power; oversized or heavy components necessitate specialized equipment.

Initial cost: Significant equipment investment makes it optimal for long-term.