Fast CNC Machining Services

Get instant quotes for CNC-machined metal/plastic parts, from prototype to mass production.

1.Tolerances as precise as 0.001 inch are available.

2.We offer 110 materials, including metals, plastics, ceramics, and composites.

3.Over 20 surface finishes are available.

4.We are ISO 9001:2015 certified.

5.Delivery times average 1-3 days.

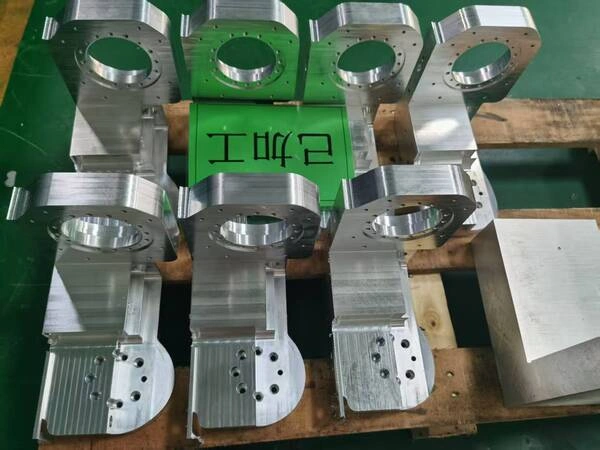

Weldo cnc machining service for metal/plastic/ceramic parts

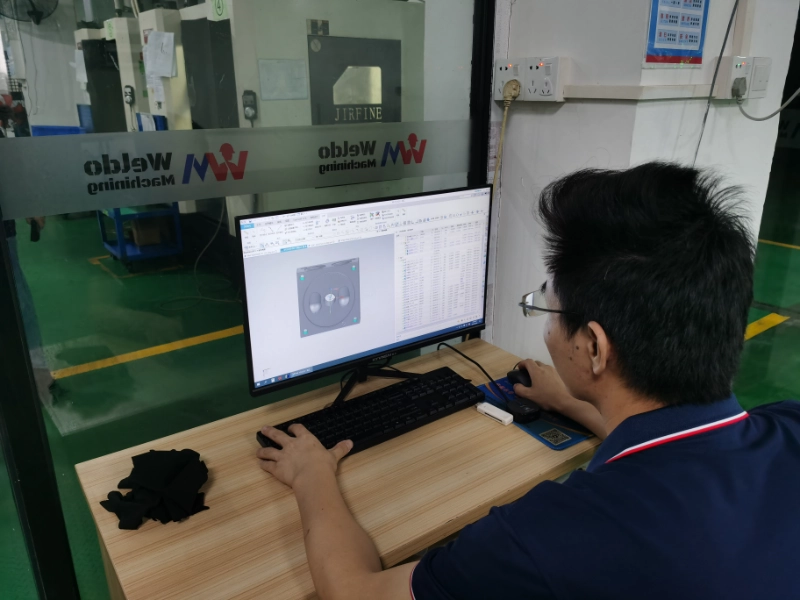

Weldo strikes the right balance between quality and cost for your prototypes, ensuring high-quality prototypes while keeping machining costs reasonable.Our machining center features over 200 CNC machines with extensive experience in milling, turning, high-speed and medium-speed EDM cutting, slow-speed EDM immersion etching, and precision grinding.ISO 9001 certification and professional quality control personnel, paired with precision measuring equipment, guarantee consistent quality for prototypes and production runs.

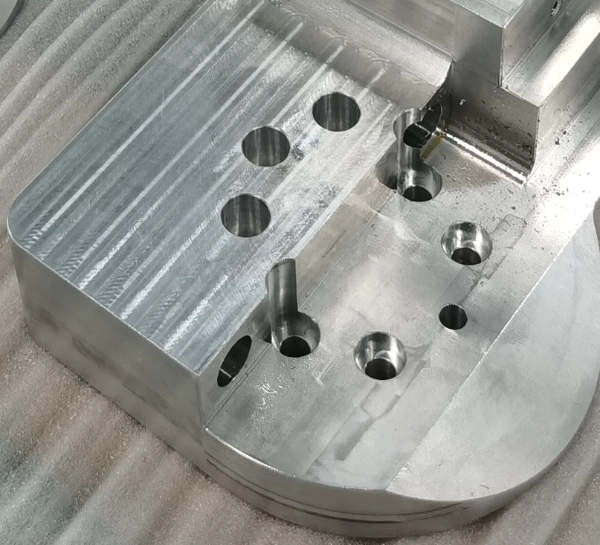

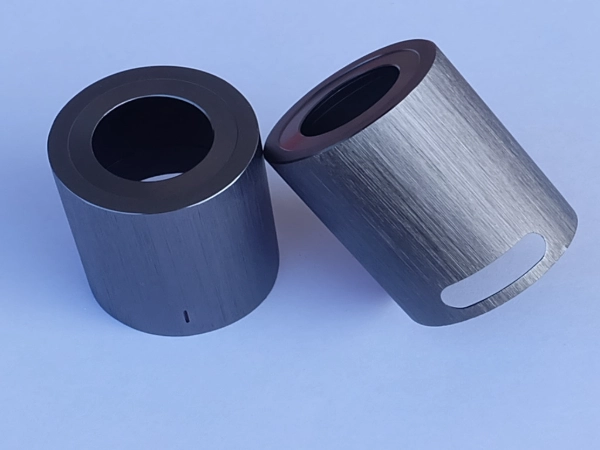

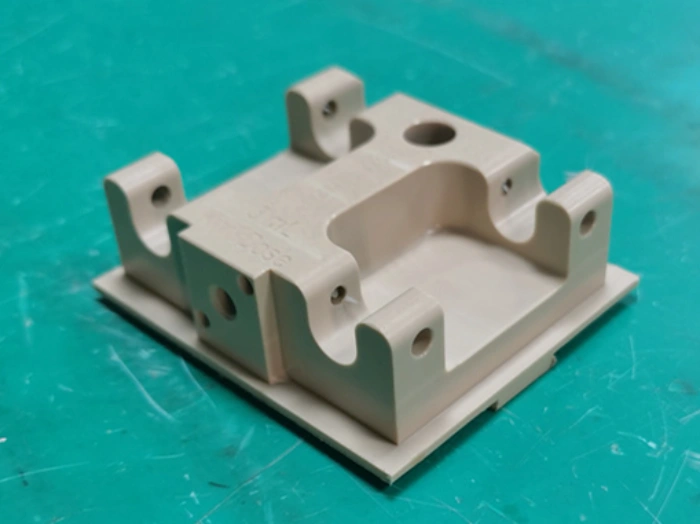

Weldo custom cnc milling parts

Own professional milling and machining service facility, featuring manual milling and turning, as well as 3-axis, 4-axis, and 5-axis CNC milling and turning machines in separate operation rooms.We can easily handle applications ranging from medical devices and aerospace to 3C electronic components and automotive parts, producing metal and plastic prototypes to customer-standard dimensions.

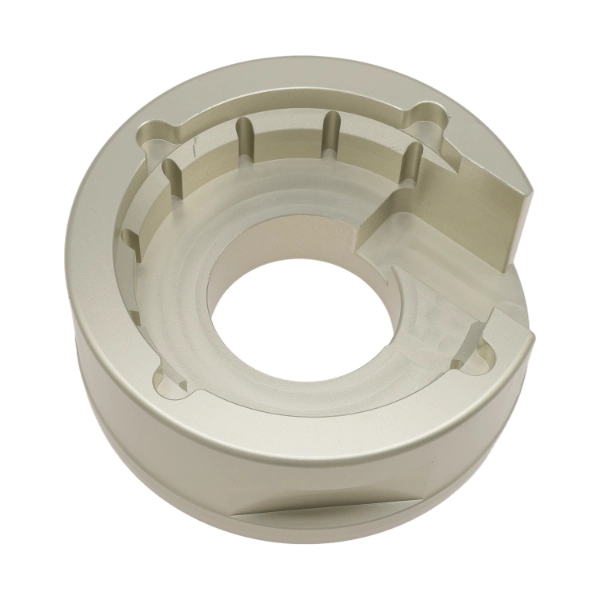

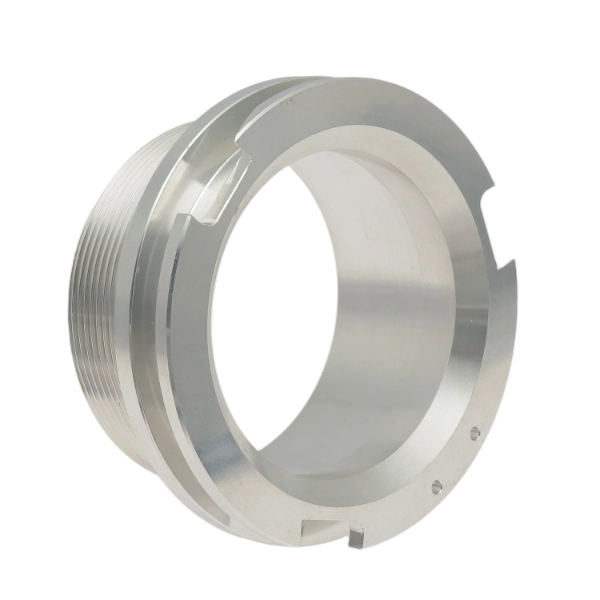

Weldo custom turning parts

Our professional engineers, with more than 10 years of production experience, can use the correct tool to set the most appropriate feed rate to complete the turning tasks of high-hardness metal or soft metal, plastic, ceramic and other materials. For symmetrical workpieces such as round, cylindrical, square, hexagonal, octagonal, etc., we can complete the delivery task as soon as 1-3 days.

Comprehensive high-standard CNC machining manufacturer

Weldo, a precision machining team comprised of engineers with 15 years of hands-on experience, stands as Dongguan’s premier professional CNC machining service provider.

One-Stop Precision Machining Services

Our core engineers boast an average of over 10 years of industry experience, mastering advanced machining techniques such as 3/4/5-axis simultaneous machining and micron-level precision control. We have successfully completed over 5,000 complex projects spanning high-demand sectors including aerospace, medical equipment, and automotive components. Equipped with multiple imported 5-axis CNC machines for processing large/small workpieces, CNC grinding beds, high/medium-speed wire EDM machines, and complex-shape slow-wire EDM equipment, we seamlessly handle the entire process chain from rough machining to surface polishing and micron-level precision treatment. This enables your product projects to enter installation testing and market launch as quickly as possible.

CNC Machining Common Materials

WELDO provides precision CNC machining services for materials ranging from common aluminum, stainless steel, alloys, and copper to plastics such as ABS and PC etc.

Metal cnc material type:

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Plastic cnc material type:

ABS

Combining the rigidity of acrylonitrile, the toughness of butadiene, and the processability of styrene, it offers excellent impact resistance (maintaining toughness even at low temperatures) with a balanced hardness and rigidity. Suitable for precision components subjected to moderate loads, it is ideal for manufacturing precision parts such as electronic and electrical enclosures, automotive ducting, interior trim components, and exterior trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

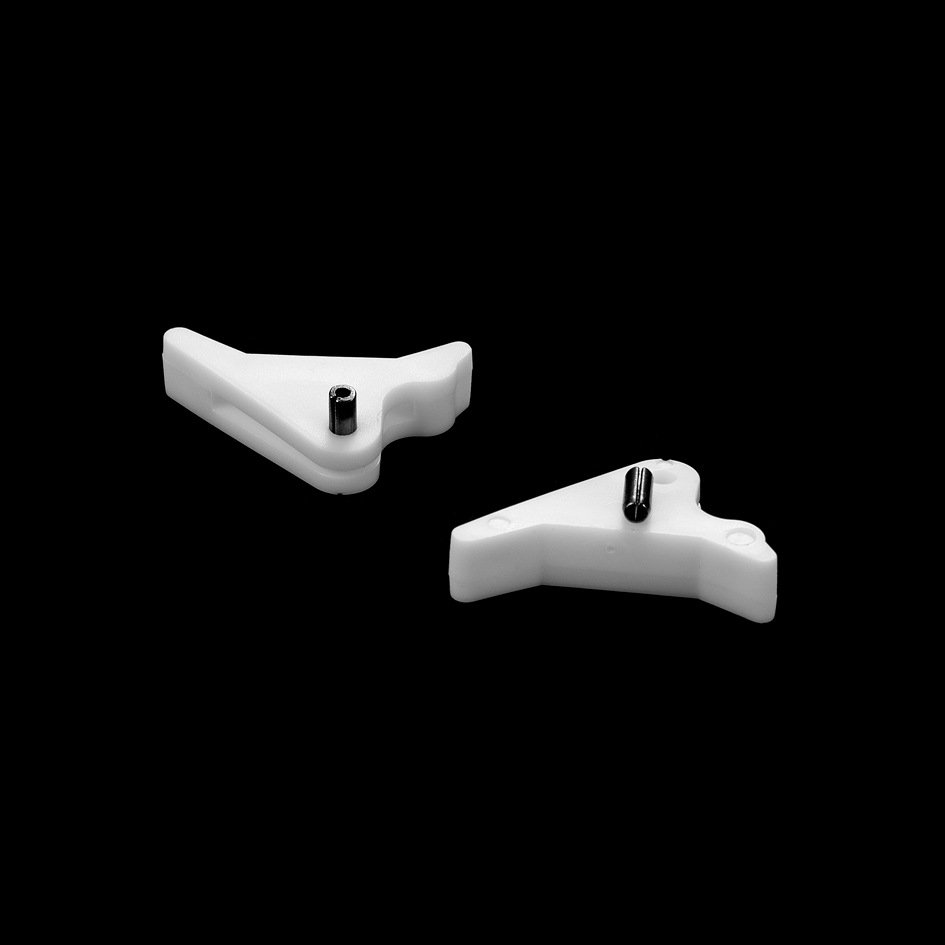

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HIPS

HIPS is a non-crystalline thermoplastic containing 5-15% rubber content, offering both high impact resistance and ease of processing. It features moderate surface hardness, low moisture absorption (0.05-0.7%), low cost, and suitability for complex structures. Widely used in appliance housings, food packaging, automotive interiors, and industrial piping, it replaces metal to meet lightweight and impact-resistant requirements.

Color : black.

Types : Impact-resistant HIPS, Brominated flame-retardant HIPS, Glass-fiber reinforced HIPS.

Surface finish :Polishing ,Sandblasting ,Coating.

Delivery time : 1-5 days.

Surface finish for CNC machining parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various precision machined parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals such as aluminum, magnesium, and titanium.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Electropolish

Removes microscopic protrusions from metal surfaces through electrochemical anodic dissolution, creating a smooth, dense surface free of residual stress and highly corrosion-resistant. Capable of processing complex metals and conductive materials.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, this process enhances hardness, strength, toughness, and wear resistance. It is suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

CNC Machining Tolerances

Our CNC machining centers operate with precision tolerances certified to industry standards, ensuring uniform dimensional accuracy for every part and drawing requirement.

| General tolerance | ±0.08mm-0.2mm (metal/plastic part) |

|---|---|

| High precision tolerance | ±0.001mm-±0.05mm (metal/plastic) |

| Wall thickness minimum | 1mm(plastic)/0.5mm(metal) |

| Min size of end mill | 1 mm |

| Min size of drill | 0.5 mm |

| Max size of machining part | cnc milling : 3000mm*1600mm*1000mm cnc turning : Dia 200mm/len : 1000mm |

| Min size of machining part | cnc milling : 5 mm*5 mm*5 mm cnc turning : Dia 2mm/len : 2mm |

| Production quantity | Prototype:1-50 pcs Small production:50-100 pcs Bulk production:100-500 pcs |

| Delivery time | Prototype : 1-5 days Bulk:need to discuss |

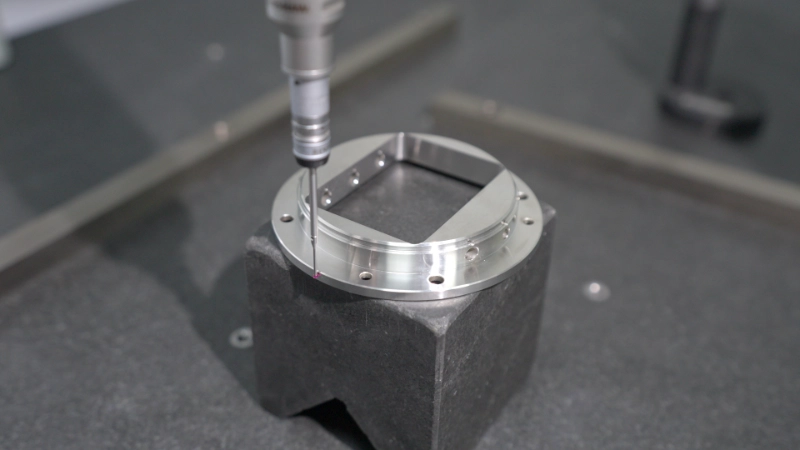

High-standard precision CNC machining for your part

At Weldo, each of our CNC machining services is tailored to your drawing requirements and precision. Our employees understand that every customer is the driving force behind our company’s growth, and that serving them well drives our company forward.

Our engineers perform dimensional measurement and control at every CNC machining step. Regardless of the quantity of your parts order, they will ultimately be sent to our quality inspection department for final inspection. We use vernier calipers, micrometers, height gauges, and projectors to measure parts. For difficult parts, we use automatic coordinate measuring machines. This ensures that the parts shipped meet your drawing’s accuracy requirements.

Our CNC machine operators and inspectors ensure that parts meet customer specifications for dimensional accuracy and quality. If a customer is dissatisfied with a product, we quickly implement adjustments to maintain our brand image.

With over 20 years of machining experience and ISO 9001 certification, we stand out in today’s CNC machining industry and earn unanimous praise from our customers.

*20+ size testing equipment *30+ quality inspectors *ISO 9001:2015 certification

Weldo cnc machining solutions

Whether your CNC precision machining project production quantity is 1 or dozens or hundreds of batches, Weldo’s processing team can flexibly schedule your project and deliver it on schedule.

Fast Prototyping

CNC machining allows for rapid prototyping of parts due to its flexibility and efficiency. We at Weldo provide fast quotes and on-time delivery, providing precision parts that meet your drawing dimensions and accuracy requirements.

Lead time : 1-3 days

Capability : 1-100 units

Get a minimum discount of 15%

Small-batch production

Small-batch CNC machining often serves as a transition from prototyping to mass production. We can further optimize production processes and details during this process, reducing your unit costs while improving quality and machining accuracy, helping you expand your sales.

Lead time : 5-15 business days

Capability : 100-1000 units

Meet your precision machining requirements

Finally, full-scale production

CNC machining is an excellent choice for producing large quantities of parts with high standards and precision. With accumulated experience in processing a variety of materials, automated and multi-axis machining equipment, WELDO can achieve comprehensive control of quality, performance, precision, and delivery speed in large-scale part production.

Lead time : 2- 5 weeks

Capability : above 1000 units

Consistent quality and high cost performance

Start your precision machining business

Upload your cad/PDF file to get quote and catalog

CNC Machining for Various Industries

From consumer electronics, automotive parts, medical devices, to aerospace, WELDO’s CNC machining services can meet the needs of producing components from small to large. We have partnered with renowned local companies in over 100 countries and regions worldwide and have received positive feedback.

CNC machining FAQ

1. What is CNC machining?

CNC machining (Computer Numerical Control machining) is a subtractive manufacturing process where computer programs control cutting tools to remove material from a workpiece, creating precise parts with tight tolerances.

2. What are the main CNC machining processes?

Common processes include CNC milling (for complex 3D shapes), CNC turning (for round or cylindrical parts), CNC drilling (for accurate holes), and CNC routing (for flat sheets and panels).

3. What materials can be machined?

CNC machining can process metals (aluminum, steel, titanium, brass), plastics (ABS, PC, PEEK, Nylon, Acrylic), and composites. Material selection depends on strength, weight, cost, and functional requirements.

4. What tolerances are achievable in CNC machining?

Standard tolerances are typically ±0.01 mm. High-precision 5-axis machines can achieve up to ±0.005 mm, and with specialized setups, tolerances as tight as ±0.002 mm may be possible.

5. What are G-codes and M-codes in CNC machining?

G-codes are programming commands that control tool movement, such as positioning and cutting paths (e.g., G00 for rapid move, G01 for linear cut). M-codes control machine functions like spindle on/off, coolant control, or tool changes (e.g., M03 for spindle on clockwise, M05 for spindle stop). Together, they form the CNC program.

6. How does CNC machining compare to 3D printing?

CNC machining offers higher accuracy, better material properties, and smoother surface finishes. 3D printing is faster and cheaper for concept prototypes, but CNC machining is preferred for functional parts and production runs.

7. Is CNC machining suitable for small-batch production?

Yes. CNC machining does not require molds, making it highly cost-effective for small to medium production runs. It also allows easy design modifications during development.

8. How long does CNC machining take?

Lead times vary by complexity and volume. Simple prototypes can be completed in 1–3 days, while complex parts or larger orders may take 1–2 weeks.

9. What industries commonly use CNC machining?

CNC machining is widely used in aerospace, automotive, medical devices, electronics, robotics, consumer products, and energy industries. It’s valued for precision, repeatability, and versatility.

10. What surface finishes are available for CNC machined parts?

Options include bead blasting (matte finish), polishing (high gloss or transparency for plastics), painting, powder coating, anodizing (for aluminum), and electroplating. The choice depends on functional and aesthetic requirements.