CNC MILLING SERVICE:

Service overview:

CNC milling can process metals such as aluminum, steel, copper, alloys, and titanium, as well as plastics like polypropylene and ceramics, fabricating the required shapes according to your drawings(CAD/pdf etc.).

Whether you require single parts or batch production, Weldo Machining offers cost-effective milling services.

Supports almost 50 materials.

Fast response time.

Accurate quotes within 30 minutes.

100% quality assurance on hardness, dimensions, tolerances, and more.

Advantage of CNC milling(mill):

High Precision—Consistently achieves tight tolerances and intricate details, surpassing manual machining capabilities.

Enhanced Productivity—Automated production with repeatable cycle times significantly shortens delivery cycles for prototypes and batch products.

Versatile Material Processing — Effortlessly machines diverse materials including metals (aluminum, copper, stainless steel, titanium), plastics, and ceramics.

Cost Reduction — Minimizes scrap through optimized toolpaths and lowers labor costs via automated operation after initial setup.

Batch Production Standardization — Ensures complete part consistency across every production run, critical for aerospace, medical devices, deep-sea operations, and other mission-critical industries.

Online cnc milling process for custom part

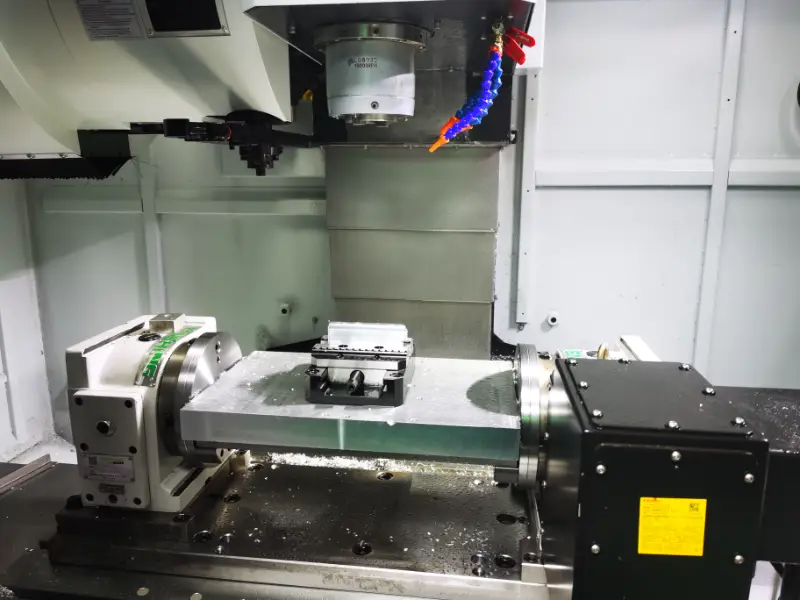

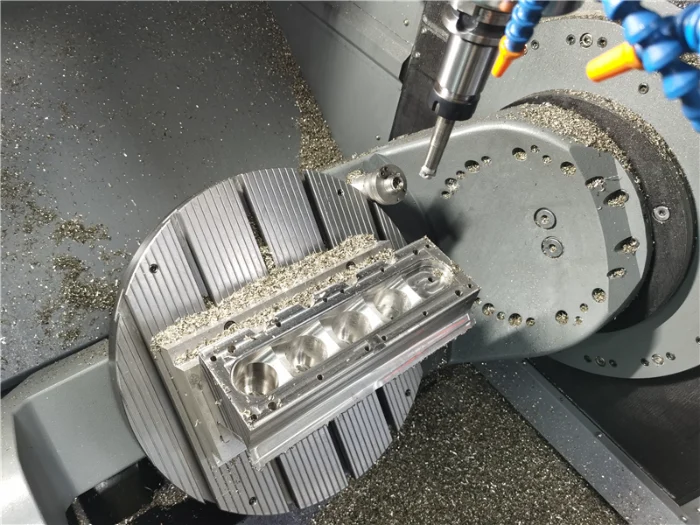

We have professional 3-axis, 4-axis, and 5-axis CNC machines. Weldo’s professional CNC milling service can help you present your design in a short time with high precision and high quality.

3-axis cnc milling

For parts with simpler designs, removing excess material in the x, y, and z directions can produce prototypes efficiently and economically.

4-axis cnc milling

The workpiece base has one more rotating plane (a-axis) than the three-axis, which is convenient for milling and drilling on the rotating surface.

5-axis cnc milling

additional rotation plane (C-axis) to control the horizontal and vertical rotation of the workpiece, making the milling process more complex and three-dimensional.

WELDO cnc milling solution

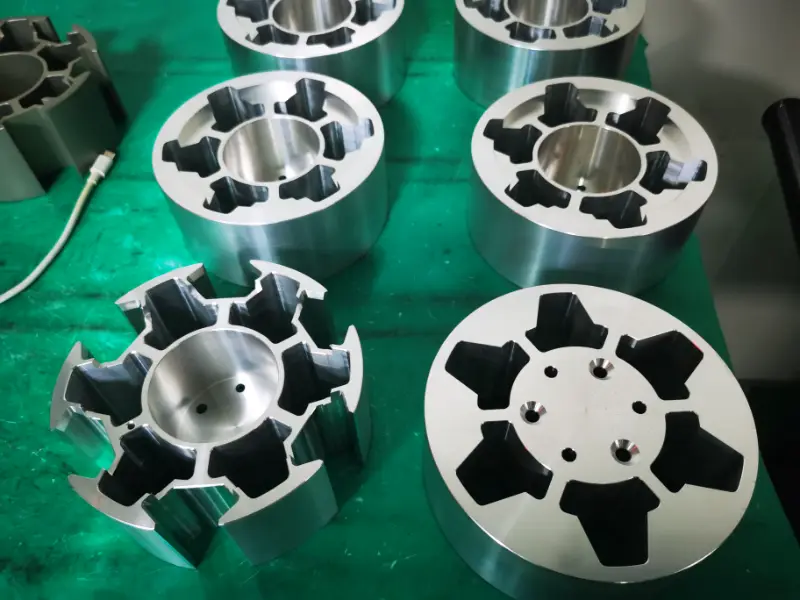

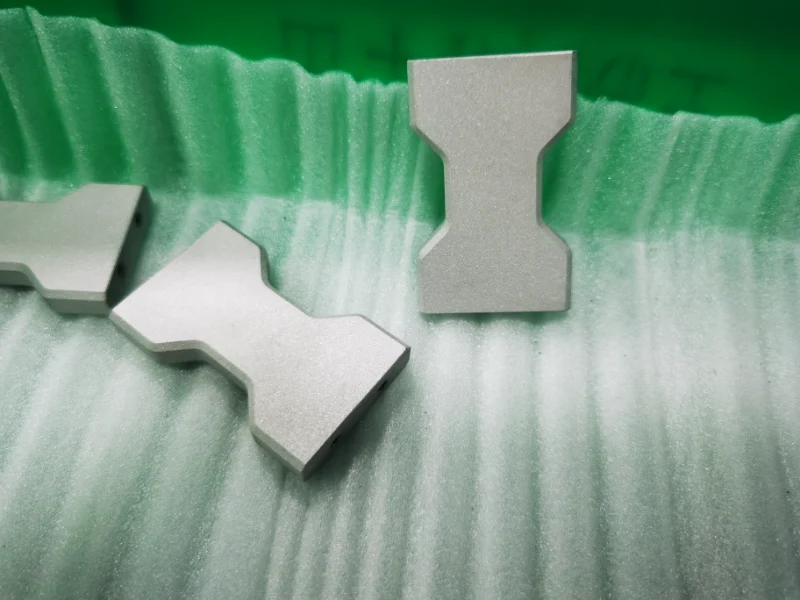

Prototyping sample

Through our experienced CNC milling engineers, we provide better and faster proofing solutions, so that your part prototype (mold) can be put into testing as soon as possible.

Small and large batch production

From small batches to large-scale parts production, our CNC milling team can always guarantee the quality of part materials and high standards of precision, ensuring that you no longer have to worry about finding a new cnc machining service provider.

CNC milling material

At Weldo, our engineering team can purchase and prepare materials according to customer needs before CNC milling. At the same time, we can provide customers with more material choices based on customer application scenarios, usage environment, cost budget, processing accuracy requirements, etc.

CNC Milling Common Materials

WELDO provides precision CNC milling services for materials ranging from common aluminum, stainless steel, alloys, and copper to plastics such as ABS and PC etc.

Metal cnc material type:

Aluminum

Aluminum is the most commonly used precision-machined component. It has a low density, a hard texture, and a soft material. Thanks to its corrosion resistance, it is widely used in aerospace, bionic bones, and automotive parts manufacturing.

Color : Silver.

Types : Aluminum 6061、7075、2024、5052、6063 and MIC-6.

Surface finish : Polishing, Brushing, Sandblasting, Chrome Plating, Anodizing, Electroplating, Powder Coating, Laser Etching.

Delivery time : 1-5 days.

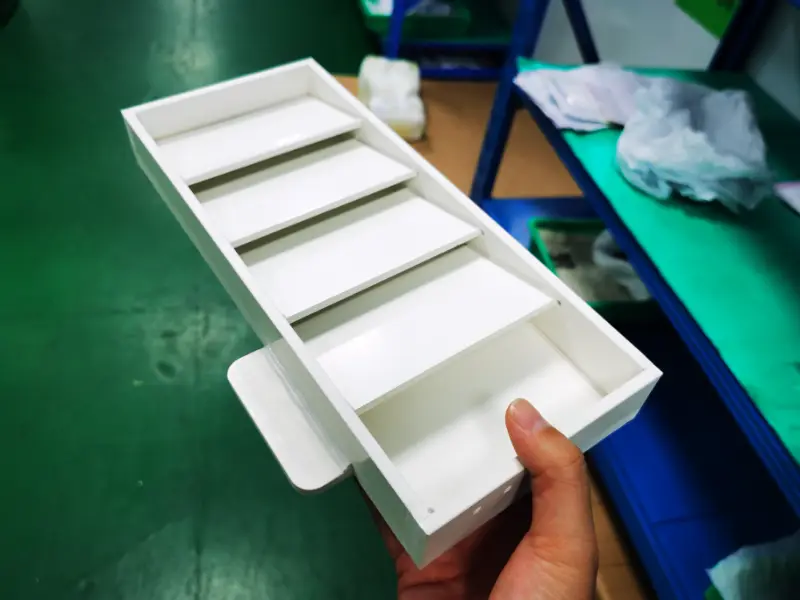

Plastic cnc material type:

ABS

ABS combines rigidity, toughness, and processability, offering strong impact resistance even at low temperatures. It is commonly used for moderate-load precision parts such as electronic enclosures and automotive trim components.

Color : Beige,black.

Types : General-purpose, flame-retardant, heat-resistant, high-impact-resistant, transparent (MBS), filled modified, alloyed, functionalized ABS.

Surface finish :Spray coating, electroplating, screen printing, laser engraving, hot stamping, vacuum coating, water transfer printing, sandblasting, anti-fingerprint coating.

Delivery time : 1-5 days.

PVC

Rigid PVC: Density approximately 1.35 g/cm³, high mechanical strength, tensile strength up to 34.5–49 MPa, elongation 20–40%, strong resistance to acids, alkalis, and oils, aging resistant, suitable for chemical and corrosive environments.

Color : White,Beige,black.

Types : Rigid PVC and Flexible PVC.

Surface finish : Painting and plating, polishing, sanding

Delivery time : 1-5 days.

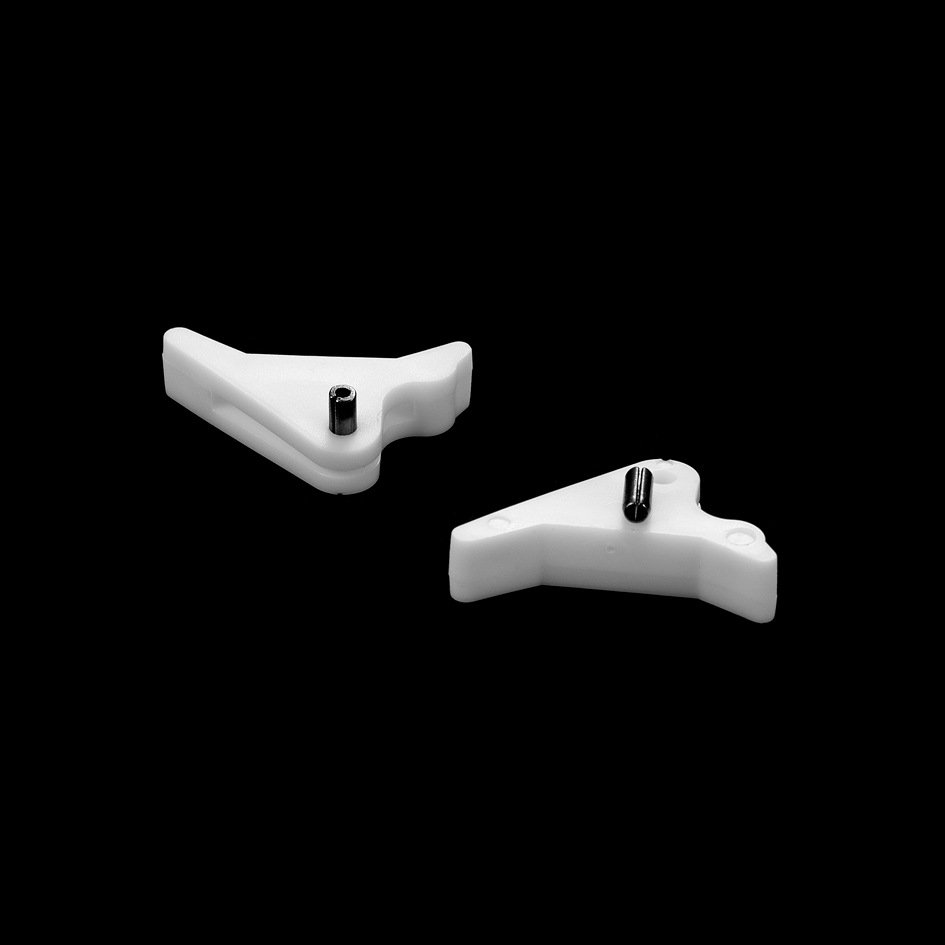

POM

High tensile strength and low friction coefficient, excellent dimensional stability, easy machinability, can replace metal as raw material for wear-resistant components such as gears and bearings, widely used in automotive industry, industrial machinery,medical tools, etc.

Color : white,black,blue,yellow,etc.

Types : POM-H, POM-C.

Surface finish : Polishing, sandblasting, chemical polishing, laser polishing, anodizing/painting.

Delivery time : 1-5 days.

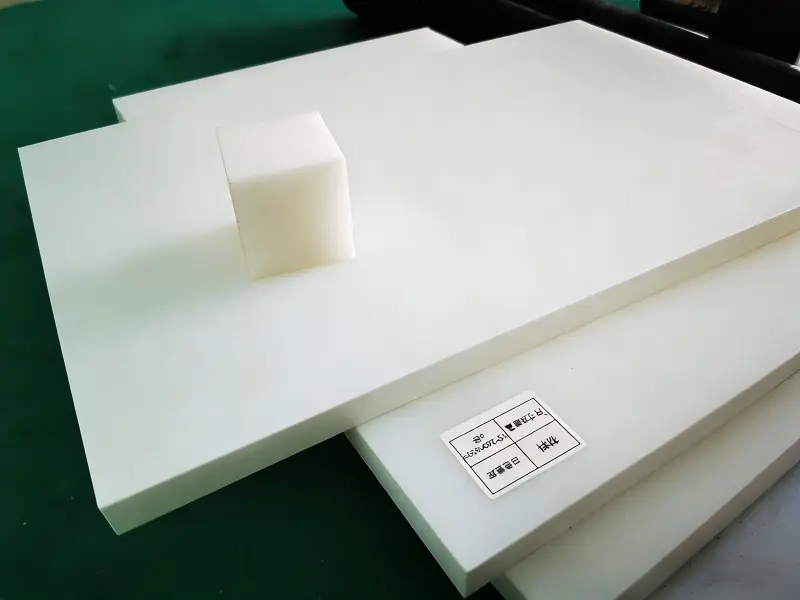

PTFE

PTFE is a high-performance engineering plastic with an extremely low friction coefficient, excellent chemical resistance, and outstanding electrical insulation. It remains stable across a wide temperature range and resists nearly all chemicals, solvents, and acids, making it ideal for precision parts such as seals, gaskets, bushings, insulators, and low-friction wear components used in chemical, medical, electronics, food, and aerospace industries.

Color : White, natural, black, filled or custom-colored.

Types : Virgin PTFE,Glass-filled PTFE,Carbon-filled PTFE,Bronze-filled PTFE,Modified PTFE

Surface finish : Machining finish, polishing, texturing, coating, engraving, anti-static treatment.

Delivery time : 1-5 days.

PMMA

With a light transmittance as high as 92%, it is hailed as “plastic crystal,” serving as material for optical components such as lenses and light guides. Its optical uniformity surpasses that of ordinary glass, while weighing only half as much. It offers easy machinability, moderate thermal stability, low shrinkage, and impact resistance. Primarily used in consumer electronics industries for display protective covers, lenses, and mobile phone frames.

Color : clear,white,black,colored.

Types : General-purpose / Impact-resistant / Heat-resistant / Pearlescent.

Surface finish : Polishing, enhanced coating, sandblasting for texture, printing for coloring, anti-scratch and anti-fingerprint treatments.

Delivery time : 1-5 days.

PC

High-performance thermoplastic with high toughness (low-temp resilient) and rigidity, ideal for CNC precision machining (cutting, drilling). Lighter than acrylic, it offers strong creep resistance and high-frequency insulation, suited for stress-resistant, insulated components. Eco-friendly via recycling by melting, used in electronics casings, spectrometer mounts, heat sinks.

Color : white or black.

Types : General Machinable/Flame Retardant/Reinforced/Blended PC.

Surface finish : Polishing, Hardening, Spraying, Laser Engraving, Electroplating, Hot Stamping.

Delivery time : 1-5 days.

FR4

FR4 is a glass-fiber-reinforced epoxy laminate with high mechanical strength, excellent electrical insulation, and strong dimensional stability. It offers good machinability, low moisture absorption, and reliable performance under mechanical load and elevated temperatures, and is commonly used for structural and insulating components such as electrical insulators, spacers, terminal blocks, mounting plates, fixtures, brackets, and support panels.

Color : Yellow, green, black, white, natural

Types : Standard FR4 / High-Tg FR4 / Halogen-free FR4

Surface finish : Machining finish, polishing, sandblasting, coating, painting, laser marking

Delivery time : 1–5 days

PA

PA (Polyamide, Nylon) exhibits tensile strength ranging from 62 to 85 MPa, low friction coefficient, and excellent heat resistance. Primarily used in high-load structural components such as gears and bearings, it facilitates the manufacturing of automotive parts, consumer electronics, and industrial machinery components.

Color : Colored.

Types : PA6, PA66, PA6T, PA9T.

Surface finish :Mechanical grinding, acid/alkali etching, hydrolysis technology, coating.

Delivery time : 1-5 days.

PE

PE (Polyethylene) is a thermoplastic material with a low melting point. During machining, tool temperature must be controlled to prevent adhesion, resulting in a smooth, burr-free surface. Its low friction and self-lubricating properties make it suitable for sliding/rotating components. It resists most acids, alkalis, salts, and organic solvents but is soluble in aromatic hydrocarbons and halogenated hydrocarbons. Common applications include food containers, trash bins, and toys.

Color : black,white,colored.

Types : LDPE, HDPE, UHMWPE, PEX, PEX-A, PEX-B.

Surface finish :Polishing, sandblasting, coating, etching.

Delivery time : 1-5 days.

PEEK

PEEK (Polyetheretherketone) is a semi-crystalline specialty engineering plastic characterized by high strength, high melting point, and low friction coefficient. It offers excellent chemical resistance and is suitable for aerospace structural components, high-temperature parts, and medical devices such as endoscopes and handles.

Color : Beige,black.

Types : CF-PEEK, GF-PEEK, PEEK with carbon black/ceramic/PTFE/graphite fillers.

Surface finish :Sandblasting, polishing, metal coating, polymer coating.

Delivery time : 1-5 days.

PP

PP (Polypropylene) is a semi-crystalline thermoplastic with a melting point of approximately 130-160°C. It exhibits excellent processing flow properties. During CNC machining, temperature control is essential (recommended range: 200-230°C). It is suitable for repeated bending operations. Tool selection must align with the material’s characteristics. Primarily used for containers, connectors, and structural components.

Color : black,white,colored.

Types : PP-H, PP-B, PP-R, HIPP.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HDPE

HDPE (High-Density Polyethylene) is a linear thermoplastic with excellent impact resistance and dimensional stability.Non-toxic and odorless, it is suitable for manufacturing valves, pump bodies, gears, sliding bearings, and as core material for surfboards.

Color : black,white.

Types : HI-HDPE, UV-HDPE, UHMWPE, Carbon Black-Filled HDPE.

Surface finish :Polishing, Sandblasting, Coating.

Delivery time : 1-5 days.

HIPS

HIPS is a non-crystalline thermoplastic containing 5-15% rubber content, offering both high impact resistance and ease of processing. It features moderate surface hardness, low moisture absorption (0.05-0.7%), low cost, and suitability for complex structures. Widely used in appliance housings, food packaging, automotive interiors, and industrial piping, it replaces metal to meet lightweight and impact-resistant requirements.

Color : black.

Types : Impact-resistant HIPS, Brominated flame-retardant HIPS, Glass-fiber reinforced HIPS.

Surface finish :Polishing ,Sandblasting ,Coating.

Delivery time : 1-5 days.

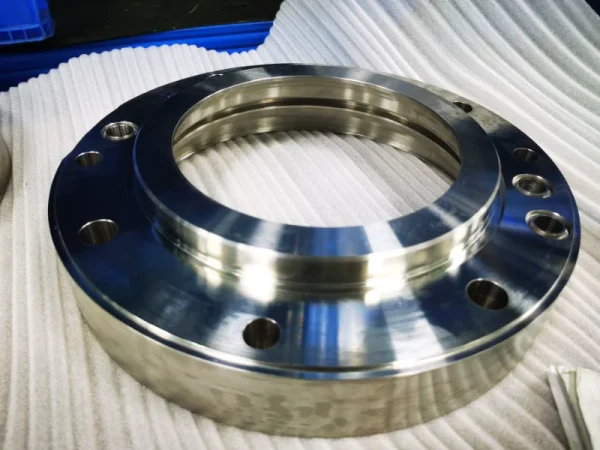

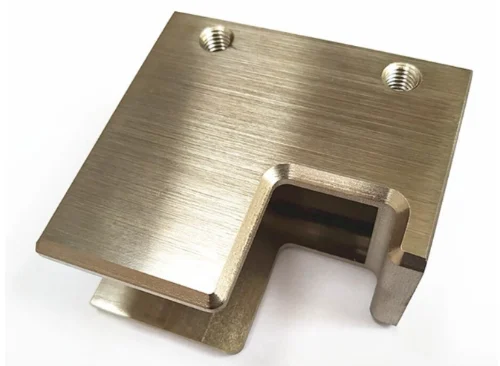

Stainless steel

Stainless steel offers strong corrosion resistance and a smooth, easy-to-clean surface. It is primarily used in kitchen equipment components, medical devices, building materials and construction, as well as automotive parts.

Color : Silver.

Types : Stainless steel 304/316/201/202/430/444/410/420/440c/2205/2507/17-4ph/17-7ph.

Surface finish : Polishing, Brushing, Sandblasting, Electroplating, Spraying, PVD (Physical Vapor Deposition), Passivation, Pickling, Coloring.

Delivery time : 2-5 days.

Copper

Possesses electrical conductivity, tensile ductility, and antimicrobial properties, primarily used for processing into crafts, decorative items, and medical equipment.

Color :Orange,yellow.

Types : copper H59/H62/Hpb59-1/C36000/HAI77-2/HSN62-1/HPb/HMn/HAl/HSn/HNi.

Surface finish : Passivation, Electroplating, Chemical Plating, Shot Peening, Sandblasting, Chemical Film Treatment, Polishing, Bright Cleaning.

Delivery time : 1-5 days.

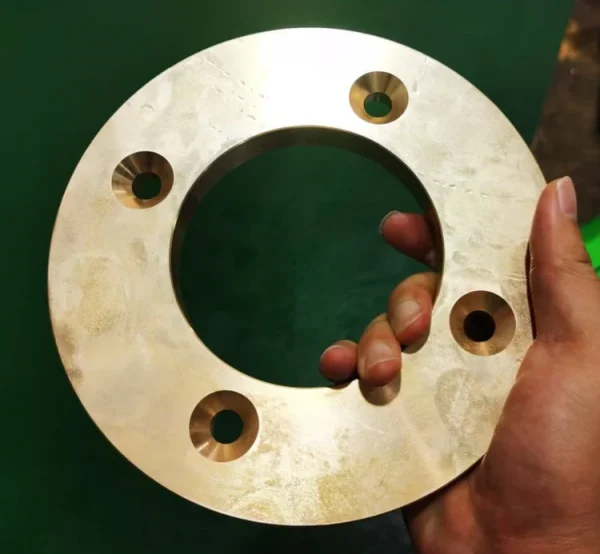

Bronze

Bronze is an alloy of copper and tin (possibly including lead, zinc, and phosphorus),low melting point (800-900°C) and excellent fluidity, along with corrosion resistance. Low-tin bronze exhibits a golden yellow hue, while high-tin bronze appears grayish-white or silver-gray. It is primarily used in mechanical manufacturing for sculptures, bearings, gears, valves, as well as in marine engineering components such as propellers, as well as marine engineering components like hull fittings and water pumps.

Color : gold/brown.

Types : Tin bronze, aluminum bronze, beryllium bronze, silicon bronze, manganese bronze.

Surface finish : Sandblasting, polishing, knurling, grinding, passivation, chemical film coating, impregnation coloring, brush/spray coloring, electroplating, anodizing, powder coating, brushing.

Delivery time : 1-5 days.

Steel

Iron alloyed with carbon (typically 0.1%-1.7%) and other alloying elements (such as chromium, nickel, manganese, etc.). By adjusting composition and heat treatment processes, diverse properties can be achieved, including high strength, high toughness, wear resistance, and corrosion resistance. It is suitable for producing components such as bolts, shafts, gears, drill bits, milling cutters, and turning tools, and is also frequently used in manufacturing engine valves and turbine blades.

Color : Silver .

Types : Steel S20C,S45C,S50C,SK85,SK95,40Cr,4140,4130,H13,D2,W1,A2,D2,M2,SKD11,ASP-23,S136.

Surface finish :Sandblasting, Mirror Finish, PVD Coating, Brushed Finish, Spray Coating, Electroplating.

Delivery time : 1-5 days

Magnesium

Magnesium has a density approximately two-thirds that of aluminum and one-quarter that of steel. Its low hardness results in minimal cutting force and reduced tool wear. With superior thermal conductivity compared to aluminum, it saves CNC machining time and material. Its strength-to-weight ratio outperforms both aluminum alloys and steel, while its damping capacity is 1.5 times that of aluminum, effectively absorbing vibrations and noise. These properties make it an ideal material for aerospace, automotive, and electronics industries.

Color : Silver.

Types : Magnesium alloy AZ91D/AM60B/AM50A/AS41B/ZK60/MB8/AZ31/WE43/ZE41/LA141/LZ91.

Surface finish : Chemical conversion coating, anodizing, nickel plating, electroplating, composite coating, spray painting, powder coating, electrophoretic coating.

Delivery time : 1-5 days.

Surface finish for CNC machining parts

Over the past 15 years, we have selected and briefly outlined more than 10 surface finished for various precision machined parts.

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity, suitable for aluminum and magnesium alloys.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance. suitable for metals such as steel, aluminum alloys, copper alloys, and titanium alloys.

Tolerance of cnc milling service

Weldo’s CNC milling can ensure that the tolerance accuracy meets customer requirements. We have a professional team responsible for measuring and recording the finished parts one by one, and remaking or reprocessing the unqualified products to ensure that the parts received by customers can be completed to high standards and high requirements. At the same time, the tolerance standards of our CNC milling of metal materials comply with ISO2768-m and the plastic milling standards comply with ISO2768-c.

| Item | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

|---|---|---|---|

| Min part size | 2000 mm × 1000 mm × 1000 mm | 1500 mm × 1000 mm × 800 mm | 1500 mm × 1000 mm × 1000 mm |

| Max part size | 5 mm × 5 mm × 5 mm | 5 mm × 5 mm × 5 mm | 5 mm × 5 mm × 5 mm |

| General tolerance | ±0.1 mm | ±0.1 mm | ±0.05 mm |

| Lead time | 1–3 days | 1–3 days | 1–3 days |

CNC milling design guideline

| Item | Design / Machining Guidelines |

|---|---|

| INTERNAL DIAMETER | The internal machining radius should be at least 1/3 of the workpiece cavity depth to avoid “tool chattering”. |

| THREADS AND THREADED HOLES | • The effective depth of the thread should be at least 1.5 to 2 times the nominal diameter• For precision fits or high-load applications, the depth should be 3 to 5 times the nominal diameter• The total depth of the threaded hole (including the ineffective depth) should be 2 to 3 thread pitches longer than the effective depth |

| MINIMUM WALL THICKNESS | • Metal CNC machining: 0.5 – 0.8 mm• Plastic CNC machining: 1.5 mm• Small wall thicknesses can increase wear, tear, and machining time costs |

| SIZE TEST | • CNC milling part: Minimum width of 0.5 mm and depth of 0.1 mm• The workpiece can be CNC routed or laser engraved according to customer needs |

| HOLES | • The recommended hole depth is 3–4 times its diameter• For example, using a 1 mm diameter tool, the recommended hole depth is no more than 4 mm |

How does CNC milling work ?

The CNC milling workflow can be divided into three core steps: “Command Generation → Machine Execution → Material Processing.” The specific principles are as follows:

I. Working Principle

CNC milling converts a part’s 3D design into digital instructions (G-code/M-code).

The CNC system (CNC controller) interprets the instructions and controls the milling machine’s spindle (tool) and worktable (workpiece) along a pre-set path. The relative motion between the tool and workpiece removes excess material, ultimately producing a component that meets the design.

II. Workflow

Step 1: Design and Programming

Engineers draw a 3D model of the part using CAD software (such as SolidWorks or AutoCAD). They then use CAM software (such as Mastercam or UG) to convert the model into machining paths (including parameters such as tool type, cutting speed, and feed rate). Finally, they generate G-codes (such as G01 for linear interpolation and G02 for circular interpolation) that the CNC system can understand.

Step 2: Clamping and Tool Setting

The workpiece is secured to the worktable (using a fixture, vise, etc.), and the relative position of the tool and workpiece is calibrated using a tool setter (determining the coordinate system origin) to ensure the correct starting point for machining.

Step 3: Automated Machining

After starting the program, the CNC controller, following G-code instructions, drives the servo motors that drive the worktable/spindle. The spindle rotates at high speed (typically 500-15,000 rpm), bringing the tool into contact with the workpiece surface. The worktable moves along the X/Y/Z axes (or the spindle moves), allowing the tool to cut along the pre-set path (e.g., milling planes, grooving, boring, threading, etc.). During the cutting process, the cooling system (cutting fluid) continuously operates to reduce tool and workpiece surface temperatures and remove chips. (A 4-axis machine has an additional rotational surface around the a-axis, while a 5-axis machine has additional rotational surfaces around the a- and c-axes.)

Step 4: Inspection and Correction

After machining is complete, use measuring tools (such as bar stock of the appropriate size, calipers, or a coordinate measuring machine) to check dimensional accuracy. If any deviation is found, re-machining can be performed by modifying the program parameters (or tool head).

Advantage of CNC milling

High Precision: Positioning accuracy of ±0.001~0.005mm, strong consistency in batch processing, scrap rate below 1%

High Efficiency: Spindle speed up to 10,000-40,000 rpm, 3-5 times more efficient than traditional milling, supports multi-process continuous machining

High Flexibility: 3-5 axis interpolation enables machining of complex surfaces and irregular structures; rapid part changeover via program switching

Broad Material Compatibility: Processes compatible with metals (steel, aluminum, titanium alloys), plastics, composite materials, and more

Automation: One-button initiation of full-process machining minimizes manual intervention; integrates with automated systems for unmanned production

Application of CNC milling

Aerospace: Machining titanium alloy turbine blades, aircraft frame cavities, and engine combustion chambers to meet high-strength and high-precision requirements

Automotive Manufacturing: Mass production of engine blocks/heads, transmission housings, and battery pack frames for new energy vehicles

Mold Industry: Fabricating injection molds/stamping dies/die-casting cavities to ensure mold dimensional accuracy and product consistency

Electronics & 3C: Machining smartphone midframes, laptop heat sinks, and micro-cavities for chip carriers (precision up to 0.01mm)

Medical Devices: Manufacturing artificial joints, surgical instrument blades, and sterile-grade equipment housings compliant with medical standards

General Machinery: Processing standard/non-standard components including gearbox housings, hydraulic valve block oil passages, and drive shaft flanges

CNC milling FAQ

What are the minimum hole diameter and wall thickness achievable with cNc milling?

Typical minimum hole diameters are approximately 0.5mm for metals and 0.3mm for plastics. Minimum wall thicknesses reach 0.5mm for metals and around 1.5mm for plastics, though these values depend on material hardness, tool precision, and machine rigidity.

What distinguishes CNC milling from 3D printing?

CNC milling employs “subtractive manufacturing” (material removal), ideal for high-precision parts in metals and rigid plastics. 3D printing uses “additive manufacturing,” suited for complex, irregular structures, though typically offering lower precision and material strength than milling.

What are the main advantages of 4-axis and 5-axis CNC milling?

Compared to 3-axis (X/Y/Z), 4-axis (+rotary axis) enables machining of inclined side structures on workpieces. 5-axis (dual rotary axes) achieves one-time complete machining of complex surfaces (e.g., impellers, mold cavities), reducing setup frequency and errors.

What files are required before CNC milling?

Provide the part’s 3D model (e.g., STL, STEP format) or 2D engineering drawings specifying dimensional tolerances, material type, and surface roughness requirements. CAM software generates machining code based on these specifications.

Which materials are unsuitable for CNC milling?

Ultra-soft materials (e.g., rubber), highly elastic materials (e.g., silicone), and brittle materials (e.g., certain ceramics) present significant machining challenges. They often result in surface roughness or tool damage and are better suited for alternative processes.