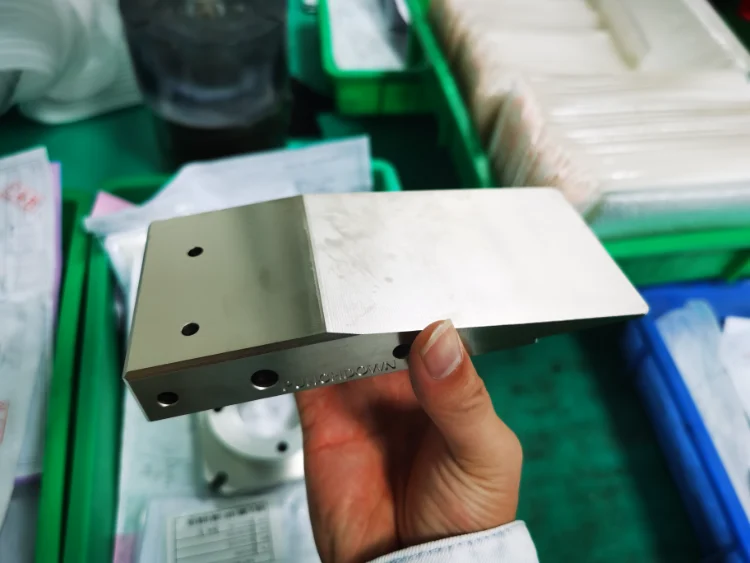

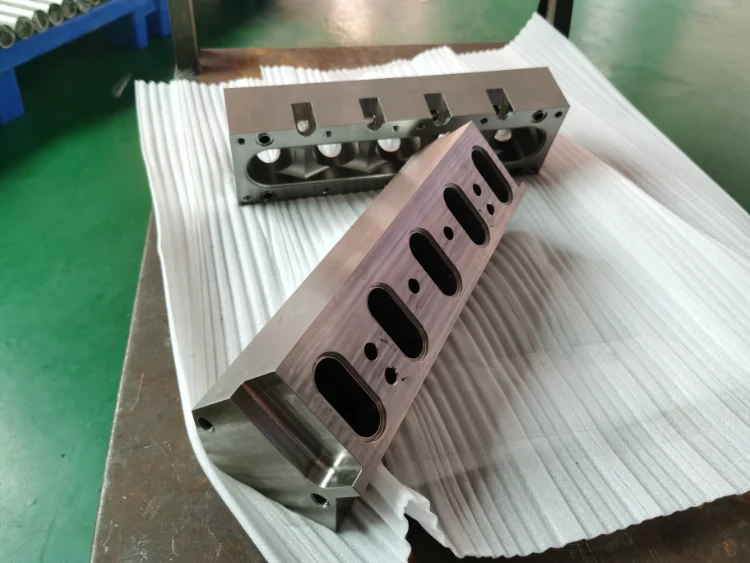

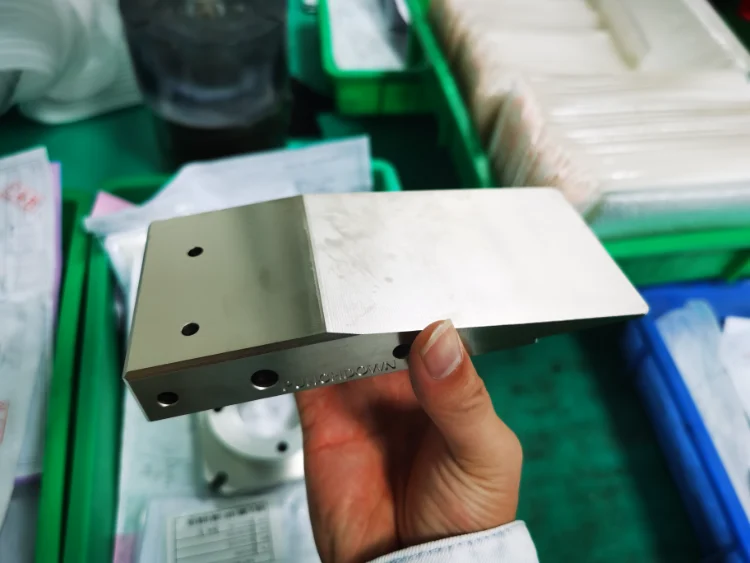

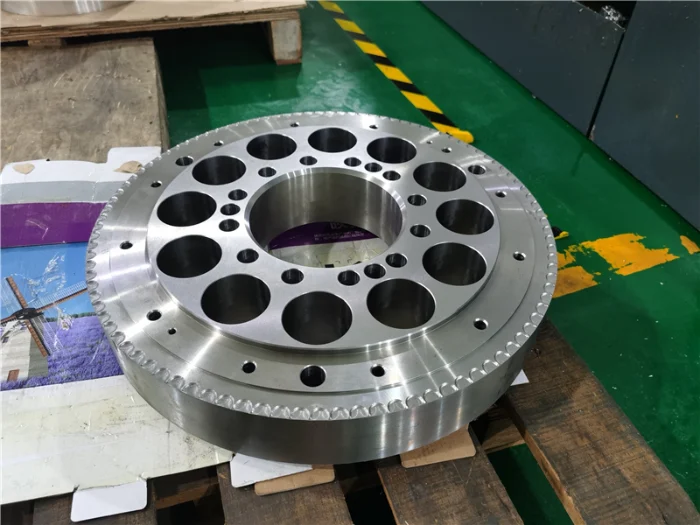

CNC steel machining

Overview:

We offer high-precision CNC steel machining services down to 0.001 inch, specializing in the manufacturing of complex parts for the aerospace, medical, and automotive. Inquire now for a customized quote and experience end-to-end process optimization and surface finish solution.

Tolerance: up to 0.001 inch

MOQ: prototype design welcomed

Price: 20-200 USD/PCs

Delivery time: 1-3 days

What is cnc steel machining ?

CNC steel machining is an automated process that uses computer programming to control machine tools to perform high-precision cutting, drilling, milling, and other operations on steel. Its core lies in the realization of precision manufacturing through digital instructions.

Carbon Steel

Carbon steel is one of the most commonly used steel grades in CNC machining. Based on carbon content, it is divided into low-carbon steel, medium-carbon steel, and high-carbon steel.

Low-carbon steel (e.g., AISI 1018, 1020)

Characteristics: Easy to cut, low cost, good plasticity.

Applications: Bolts, brackets, machine bases, lathe parts, etc.

Medium-carbon steel (e.g., AISI 1045)

Characteristics: Combines strength and toughness, good machinability.

Applications: Shafts, gears, couplings, hydraulic parts.

High-carbon steel (e.g., AISI 1095)

Characteristics: High hardness, strong wear resistance.

Applications: Cutting tools, springs, measuring tools, stamping dies, etc.

Tool steel

Used for manufacturing molds and cutting tools, extremely high hardness and excellent wear resistance. Common types include D2, O1, A2, etc.

Applications: Molds, punches, cutting tools, forming tools, etc.

Alloy steel

Adding alloying elements such as chromium, molybdenum, nickel, and vanadium to carbon steel improves its strength, wear resistance, and toughness.

Cr-Mo steel (e.g., 4140, 4340)

Features: High strength, impact resistance, fatigue resistance.

Applications: Aerospace parts, automotive crankshafts, mold components.

Ni-Cr steel (e.g., 8620)

Features: Can be carburized, possesses high surface hardness and good toughness.

Applications: Gears, bearing sleeves, transmission components.

Special steels

Including heat-resistant steel, high-speed steel, duplex steel, etc., used in extreme environments or special industries.

Examples:

H13 hot work die steel: Suitable for high-temperature molds.

M2 high-speed steel: Used for manufacturing high-cutting-speed cutting tools.

Surface finish for CNC machining parts

Based on over 15 years of CNC machining experience, we have compiled the following list of surface finish processes used for various precision-machined parts made from steel material.

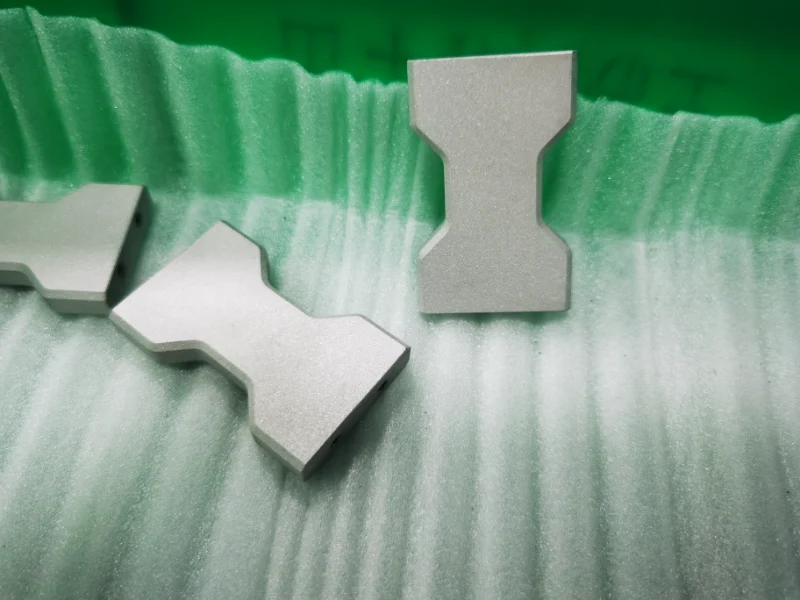

Machined finish

The prototype processed by the machine tool retains traces of tool machining.

Anodizing

Anodizing enhances the corrosion and wear resistance of metals and enables coloring and coating, suitable for metals.

Polish

Polishing enhances surface finish and aesthetic appeal, suitable for materials such as metals, ceramics, plastics, and PMMA.

Sand blasting

Sandblasting involves propelling abrasive material at high pressure or mechanically onto a workpiece to achieve a clean, roughened, and matte finish.

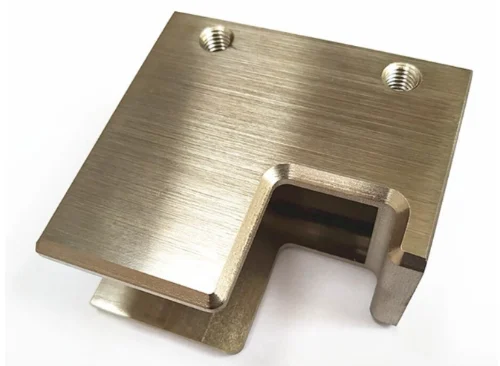

Brushed finish

Brushed finish creates a textured pattern on metal surfaces, enhancing aesthetic appeal. Suitable for aluminum, copper, stainless steel, and other materials.

Powder coating

Powder coating is applied to the workpiece surface via electrostatic adhesion, then cured at high temperatures to form a dense coating, enhancing the corrosion resistance of metal and plastic surfaces.

Electroplating finish

Metal plating is deposited onto material surfaces through electrolytic processes to enhance corrosion resistance and wear resistance. This technique is suitable for metals and certain plastics.

Black oxidize

A black oxide coating is formed on metal surfaces through chemical oxidation, offering low cost, a simple process, and reduced light reflection.

Heat treatment

By altering the internal microstructure of metallic materials through heating, enhances hardness, strength, toughness, and wear resistance.

Alodine

Forms a protective coating on surfaces through chemical conversion, enhancing corrosion resistance and adhesion. Environmentally friendly with excellent conductivity.

Advantage of cnc machined steel parts

High Precision: Errors can be controlled within ±0.005mm, ensuring batch consistency.

Example: Aero-blade thickness error ≤0.01mm, improving airflow efficiency.

Material Performance Optimization: Precise control of cutting parameters avoids heat-induced hardness reduction.

Example: During 42CrMo steel machining, proper cooling prevents tempering and softening.

Complex Structure Machining: Five-axis linkage technology enables one-time forming of multi-faceted and curved surfaces.

Example: Simultaneous machining of turbocharger housing flow channels and interfaces.

Application area of cnc machined steel parts

Aerospace: Aircraft structural components, engine parts (requiring high temperature/high pressure resistance).

Automotive Industry: Engine blocks, drive shafts (emphasizing strength and wear resistance).

Energy Equipment: Wind turbine gears, solar panel mounting systems (adaptable to harsh environments).

Medical Equipment: Orthopedic implants, surgical instruments (requiring biocompatibility).

Construction Machinery: Excavator track frames, crane booms (load-bearing capacity preferred).

FAQ of cnc steel machining

What are the requirements for steel material in CNC steel machining? Can commercially available steel be used directly?

No, commercially available steel cannot be used directly. The material must be confirmed to match the drawings, and a test report must be provided to avoid substandard performance.

How to solve the problem of scratches or burrs on the steel surface during machining?

Scratches/burrs are mostly caused by tool wear or improper parameters.

Tools: Replace with coated tools (e.g., TiAlN);

Parameters: Reduce feed rate (e.g., 0.1mm/rpm), increase cutting fluid;

Post-processing: Light burrs are sanded, heavy burrs are electrolytically machined.

What is the achievable precision of CNC steel machining? How to ensure batch consistency?

Ordinary precision ±0.05mm, high precision (e.g., aerospace parts) within ±0.005mm.

Equipment: Use a high-rigidity CNC machine tool (e.g., five-axis), calibrate regularly;

Process: Fixed path and parameters;

Inspection: Online measurement and real-time compensation.

How to avoid deformation when machining thick steel plates or large steel parts?

Thick parts are prone to deformation due to cutting forces, requiring:

Clamping: Multi-point support or vacuum chuck;

Cutting: Layered removal of allowance (≤5mm each time), symmetrical machining;

Heat treatment: Stress-relieving annealing after rough machining (550℃ for 2 hours).

What are the main factors determining the cost of CNC steel machining? How to reduce costs?

Cost composition:

Equipment: High-precision machine tools have high depreciation;

Tools: Carbide tools are expensive;

Time: Machining time affects labor and energy consumption.

Cost reduction methods:

High-speed cutting (speed ≥10000rpm) to shorten time;

Extending tool life with coatings (e.g., TiN coating increases life by 2-3 times);

Spreading costs when batch size ≥100 pieces, reducing unit price by 30%-50%.