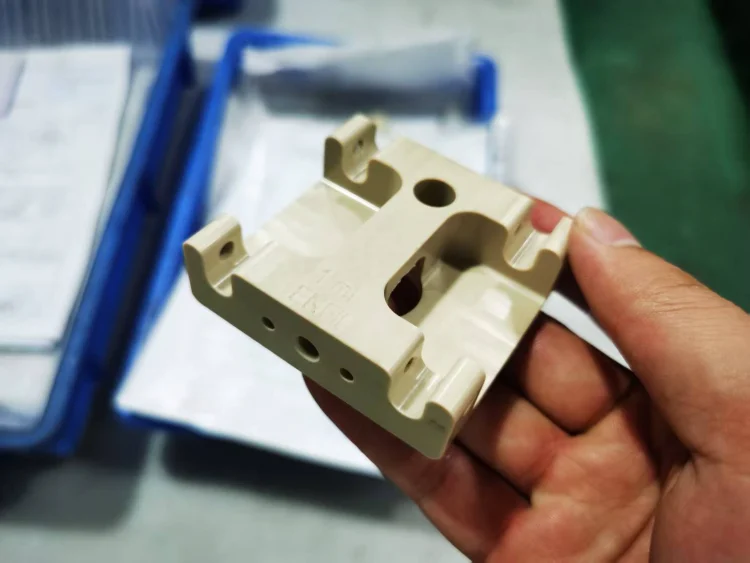

Peek cnc machining

Overview

We can achieve an accuracy of 0.005mm in Peek CNC machining. If you would like to learn more about peek machining case studies and pricing, please feel free to contact us.

Tolerance: up to 0.005 mm

MOQ: 1 PCs

Machining process: cnc milling/turning/grinding etc.

Pricing: 30-500 USD/PCs

What is peek cnc machining ?

PEEK is a semi-crystalline thermoplastic that is heat-resistant (can operate continuously at 260℃), has strong mechanical properties, is resistant to chemical corrosion, has good biocompatibility, and is also wear-resistant and radiation-resistant. Through milling using CNC machine tools according to G-code instructions, complex shapes can be manufactured with high precision, meeting the stringent requirements for dimensional accuracy and surface quality in fields such as medical and aerospace.

Types of peek for cnc machining

PEEK is a commonly used material in CNC machining. Its properties are modified by adding reinforcing agents or combining it with other materials. Specific classifications are as follows:

Pure PEEK

Unreinforced PEEK: High temperature resistance and chemical corrosion resistance; used in electronic insulation components, food processing parts, etc.

Glass Fiber Reinforced PEEK (PEEK-GF): Improved rigidity, strength, and heat resistance; used in automotive gears, oil screens, etc.

Carbon Fiber Reinforced PEEK (PEEK-CF): Higher strength, modulus, and wear resistance; used in aerospace and high-end automotive parts.

PEEK Composite Materials

PEEK-PI: Enhanced heat resistance and chemical corrosion resistance; used in deep-sea oil fields and nuclear power equipment components.

PEEK-PTFE: Improved self-lubricating properties; used in bearings, seals, and other low-friction components.

PEEK-PPS: Combines heat resistance, rigidity, and chemical stability; used in automotive engine covers and electronic components.

PEEK-PPSU: Improved toughness and impact resistance; used in medical devices and sports equipment components.

Specialty PEEK Materials

Medical-grade PEEK: Excellent biocompatibility, used in orthopedic instruments, artificial joints, etc.

Bearing-grade PEEK: Self-lubricating and highly wear-resistant, used in bearings, sliders, and other components.

Surface finish for cnc machining Peek parts

Based on over 15 years of CNC plastic machining experience, we have compiled the following list of surface finish processes used for various precision-machined parts made from peek material.

| Surface Finish | Description | Typical Applications |

|---|---|---|

| As-Machined | Smooth machined surface with fine tool marks; maintains excellent dimensional stability and material properties. | Aerospace, medical, precision mechanical parts |

| Polishing | Mechanical polishing to reduce surface roughness and improve smoothness without affecting material integrity. | Parts requiring low friction or clean surfaces |

| Sandblasting | Creates a uniform matte finish to hide machining marks and improve visual consistency. | Non-contact surfaces, cosmetic areas |

| Laser Engraving | Permanent marking of logos, part numbers, or serial codes with high precision and durability. | Identification and traceability |

| Printing (Limited) | Silk screen or pad printing with surface pretreatment; adhesion depends on application requirements. | Labels, low-wear markings |

| Functional Coating (Limited) | Special coatings applied after surface activation to enhance properties such as anti-static or wear resistance. | Specialized industrial applications |

Advantage of peek cnc machining

High Precision and Repeatability: Tolerances up to ±0.001 inches, suitable for demanding applications such as medical and aerospace, ensuring strong dimensional consistency in mass production.

Complex Structure Machining: Supports turning, milling, drilling, and other processes, enabling the manufacture of irregularly shaped parts (such as custom implants and stents) without molds.

Intact Performance Preservation: Mechanical cutting avoids thermal degradation, preserving PEEK’s high-temperature resistance (260°C), corrosion resistance, and high strength.

Flexibility and Low Cost: Small-batch production eliminates the need for molds, facilitating design modifications and shortening development cycles.

Surface Stability: Low creep and low water absorption (<0.5%), preventing deformation over long-term use, suitable for load-bearing or humid environments.

Applications of PEEK CNC Machining:

Medical: Temporary implants (skull plates, spinal fusion devices), surgical instruments, in vitro diagnostic equipment components.

Aerospace: High-temperature resistant stents, vacuum seals, lightweight gears/bearings.

Automotive: High-temperature resistant transmission gears, corrosion-resistant pumps and valves, fluid management system components.

Electronics and Semiconductors: Insulating stents, heat dissipation substrates, precision connectors. Industrial Energy: Corrosion-resistant pump bodies for chemical industry, downhole seals for oil wells, and wear-resistant casings.

FAQ of peek cnc machining

Is PEEK material suitable for CNC machining, and why?

PEEK is very suitable for CNC machining. It has high mechanical strength, high temperature resistance, chemical corrosion resistance, and dimensional stability. It is not easily deformed or burr-prone during machining, and its cutting performance is also good, ensuring high precision and high quality of parts.

What precautions should be taken during PEEK CNC machining?

Three points should be noted. First, use coolant or lubricant to cool the high-temperature chips to prevent material melting; second, take anti-static measures to avoid dust adsorption and affecting precision; third, pay attention to the clamping method to prevent part deformation and damage.

How should cutting tools be selected for PEEK CNC machining?

Select cutting tool materials with high hardness, wear resistance, and heat resistance, such as carbide tools. Select the tool type according to the shape of the part and machining requirements, such as end mills for milling planes and drills for drilling holes, and keep the cutting edge sharp.

How to improve the production efficiency of PEEK CNC machining?

Optimize the toolpath during programming, and plan it reasonably using CAM software; select appropriate cutting parameters, and experiment to find the best combination; batch machine similar parts; regularly maintain the equipment to keep it in good condition.

How to choose the right PEEK material for CNC machining?

Select the PEEK grade based on the part’s application environment and performance requirements, considering material purity and quality, supply availability, and cost-effectiveness. Consult with professional suppliers or processors for advice.